Page 128

TEST 65 – TEST STARTER MOTOR

CONDITIONS AFFECTING STARTER MOTOR

PERFORMANCE:

1. A binding or seizing condition in the starter motor bearings.

2. A shorted, open or grounded armature.

a. Shorted armature (wire insulation worn and

wires touching one another). Will be indicated

by low or no RPM.

b. Open armature (wire broken) will be indicated

by low or no RPM and excessive current draw.

c. Grounded armature (wire insulation worn and wire

touching armature lamination or shaft). Will be

indicated by excessive current draw or no RPM.

3. A defective starter motor switch.

4. Broken, damaged or weak magnets.

5. Starter drive dirty or binding.

DISCUSSION:

Test 62 verified that circuit board action is delivering

DC voltage to the starter contactor relay (SCR). Test

63 verified the operation of the SCR. Test 64 verified

the operation of the starter contactor (SC). Another

possible cause of an “engine won’t crank” problem is

a failure of the starter motor.

PROCEDURE:

The battery should have been checked prior to this

test and should be fully charged.

Set a VOM to measure DC voltage (12 VDC). Connect

the meter positive (+) test lead to the starter contactor

stud which has the small jumper wire connected to

the starter. Connect the common (-) test lead to the

starter motor frame.

Set the AUTO-OFF MANUAL Switch to its “MANUAL”

position and observe the meter. Meter should indicate

battery voltage, starter motor should operate and

engine should crank.

RESULTS:

1. If battery voltage is indicated on the meter but starter

motor did NOT operate, remove and bench test the

starter motor (see following test).

2. If battery voltage was indicated and the starter motor tried

to engage (pinion engaged), but engine did NOT crank,

check for mechanical binding of the engine or rotor.

If engine turns over slightly, go to Test 77 “Check and

Adjust Valves.”

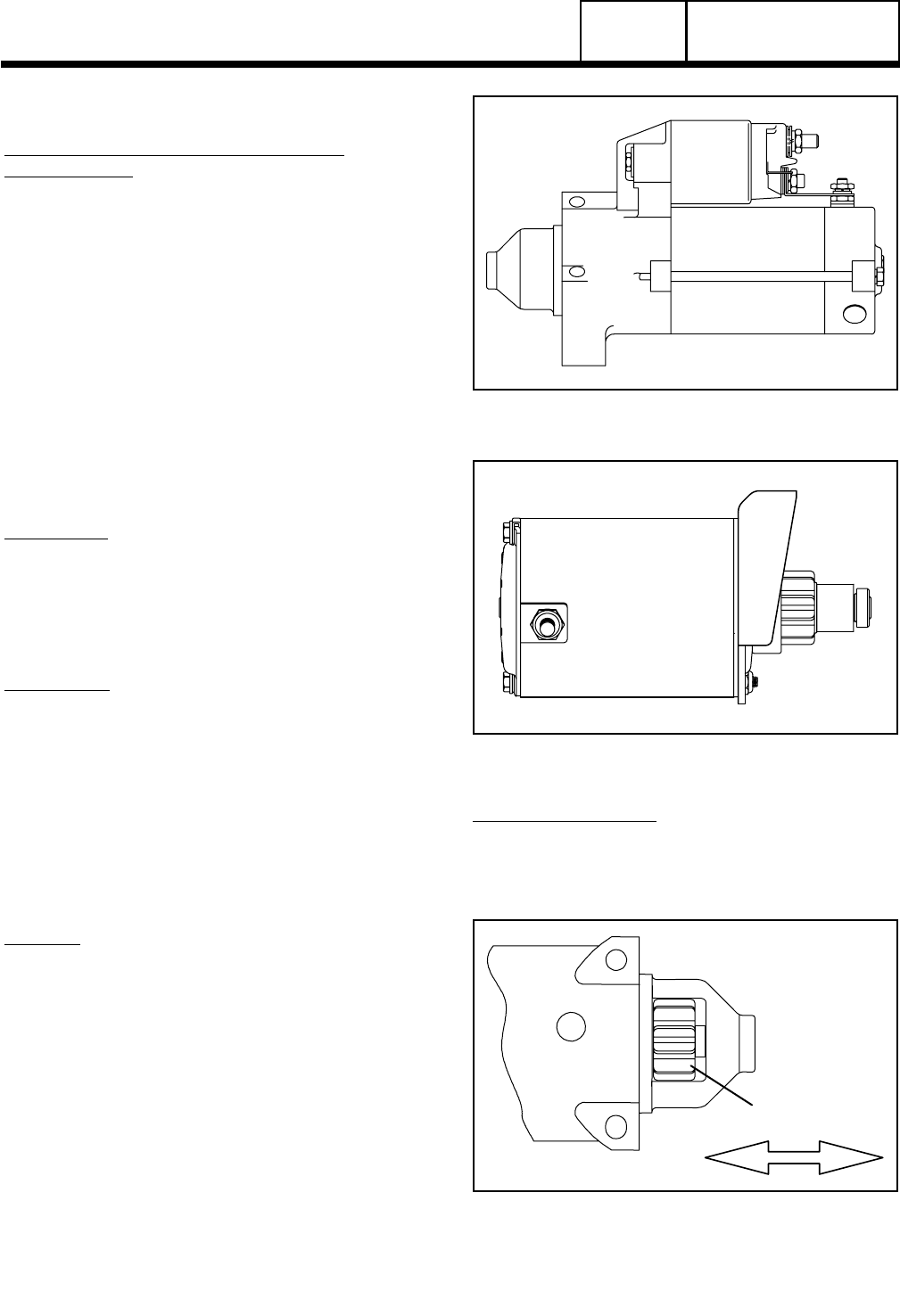

Figure 10. Starter Motor (V-Twin Engines)

Figure 11. Starter Motor (Single Cylinder Engines)

CHECKING THE PINION:

When the starter motor is activated, the pinion gear

should move and engage the flywheel ring gear. If the

pinion does not move normally, inspect the pinion for

binding or sticking.

PINION

Figure 12. Check Pinion Gear Operation (V-Twin)

PART 4

DC CONTROL

SECTION 4.4

DIAGNOSTIC TESTS