AC GENERATORS

SECTION 2.4

DIAGNOSTIC TESTS

INTRODUCTION

This section is provided to familiarize the service

technician with acceptable procedures for the test-

ing and evaluation of various problems that could be

encountered on standby generators with air-cooled

engine. Use this section of the manual in conjunction

with Section 2.3, “Troubleshooting Flow Charts”. The

numbered tests in this section correspond with those

of Section 2.3.

Test procedures in this section do not require the use

of specialized test equipment, meters or tools. Most

tests can be performed with an inexpensive volt-

ohm-milliammeter (VOM). An AC frequency meter is

required, where frequency readings must be taken. A

clamp-on ammeter may be used to measure AC loads

on the generator.

Testing and troubleshooting methods covered in this

section are not exhaustive. We have not attempted to

discuss, evaluate and advise the home standby ser-

vice trade of all conceivable ways in which service and

trouble diagnosis might be performed. We have not

undertaken any such broad evaluation. Accordingly,

anyone who uses a test method not recommended

herein must first satisfy himself that the procedure or

method he has selected will jeopardize neither his nor

the product’s safety.

SAFETY

Service personnel who work on this equipment must

be made aware of the dangers of such equipment.

Extremely high and dangerous voltages are present

that can kill or cause serious injury. Gaseous fuels are

highly explosive and can be ignited by the slightest

spark. Engine exhaust gases contain deadly carbon

monoxide gas that can cause unconsciousness or

even death. Contact with moving parts can cause seri-

ous injury. The list of hazards is seemingly endless.

When working on this equipment, use common

sense and remain alert at all times. Never work on

this equipment while you are physically or mentally

fatigued. If you don’t understand a component, device

or system, do not work on it.

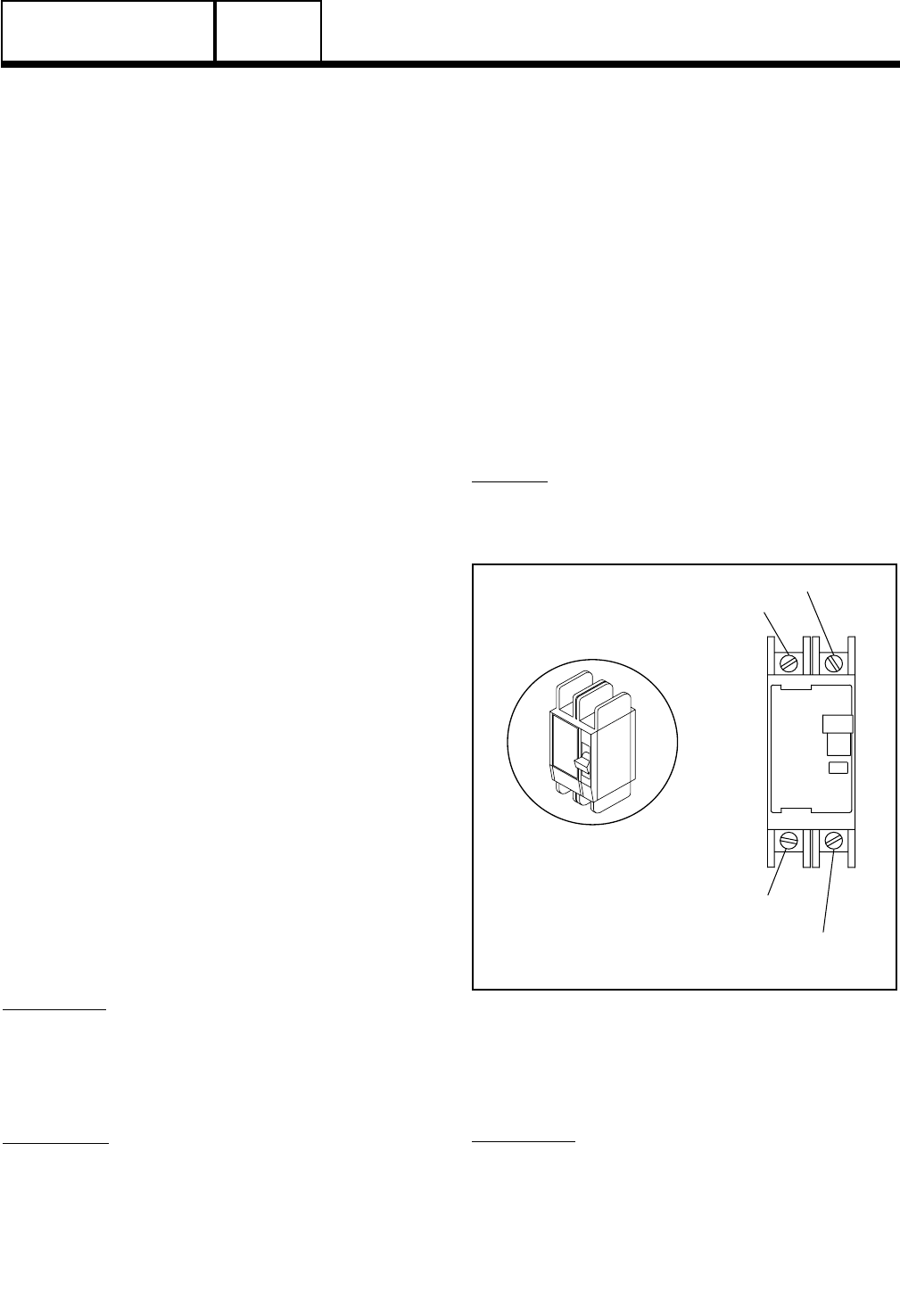

TEST 1 – CHECK MAIN CIRCUIT BREAKER

DISCUSSION:

Often the most obvious cause of a problem is over-

looked. If the generator main line circuit breaker is set

to OFF or “Open”, no electrical power will be supplied

to electrical loads. If loads are not receiving power,

perhaps the main circuit breaker is open or has failed.

PROCEDURE:

The generator main circuit breaker is located on the

control panel. If loads are not receiving power, make

sure the breaker is set to “On” or “Closed”.

If you suspect the breaker may have failed, it can be

tested as follows (see Figure 1):

1. Set a volt-ohm-milliammeter (VOM) to its “R x 1” scale

and zero the meter.

2. With the generator shut down, disconnect all wires from

the main circuit breaker terminals, to prevent interaction.

3. With the generator shut down, connect one VOM test

probe to the Wire 11 terminal of the breaker and the

other test probe to the Wire E1 terminal.

4. Set the breaker to its “On” or “Closed” position. The VOM

should read CONTINUITY.

5. Set the breaker to its OFF or “Open” position and the

VOM should indicate INFINITY.

6. Repeat Steps 4 and 5 with the VOM test probes con-

nected across the breaker’s Wire 44 terminal and the E2

terminal.

RESULTS:

1. If the circuit breaker tests good, go on to Test 2.

2. If the breaker tests bad, it should be replaced.

O

F

F

WIRE 11

TERMINAL

E1 TERMINAL

E2 TERMINAL

WIRE 44

TERMINAL

Figure 1. Generator Main Circuit Breaker Test Points

TEST 2 – CHECK AC OUTPUT VOLTAGE

DISCUSSION:

A volt-ohm-milliammeter (VOM) may be used to check

the generator output voltage. Output voltage may be

checked at the unit’s main circuit breaker terminals.

Refer to the unit’s DATA PLATE for rated line-to-line

and line-to-neutral voltages.

PART 2

Page 41