AC GENERATORS

SECTION 2.4

DIAGNOSTIC TESTS

5. Turn the Main Breaker to the "ON" or CLOSED position.

6. Set a VOM to measure resistance.

7. Connect one meter test lead to Wire 11 on the load side

of the main breaker. Connect the other meter test lead

to Wire 22 (power winding). Note the resistance read-

ing and compare to the specifications in the front of this

manual.

8. Connect one test lead to stator lead Wire 44 on the load

side of the main breaker. Connect the other test lead to

stator lead Wire 33 (power winding). Note the resistance

reading and compare to the specifications in the front of

this manual.

Note: Wire 11 and Wire 44 could be switched on

the main breaker. If an INFINITY reading is indi-

cated try putting the meter leads on the other

output terminal of the breaker. If INFINITY is still

read then an actual fault may exist.

9. Connect one test lead to Wire 22 at the voltage regula-

tor. Connect the other test lead to Wire 11 at the voltage

regulator (power winding sense leads). Note the resis-

tance reading and compare to the specifications in the

front of this manual.

TEST WINDINGS FOR A SHORT TO GROUND:

10. Make sure all leads are isolated from each other and

are not touching the frame.

11. Connect one test lead to a clean frame ground. Connect

the other test lead to stator lead Wire 11 on the load

side of the main circuit breaker.

a. The meter should read INFINITY.

b. Any reading other than INFINITY indicates a

“short-to-ground” condition.

12. Repeat Step 11 using stator lead Wire 33.

13. Repeat Step 11 using Wire 22 at the voltage regulator.

14. Repeat Step 11 using Wire 6 at the voltage regulator.

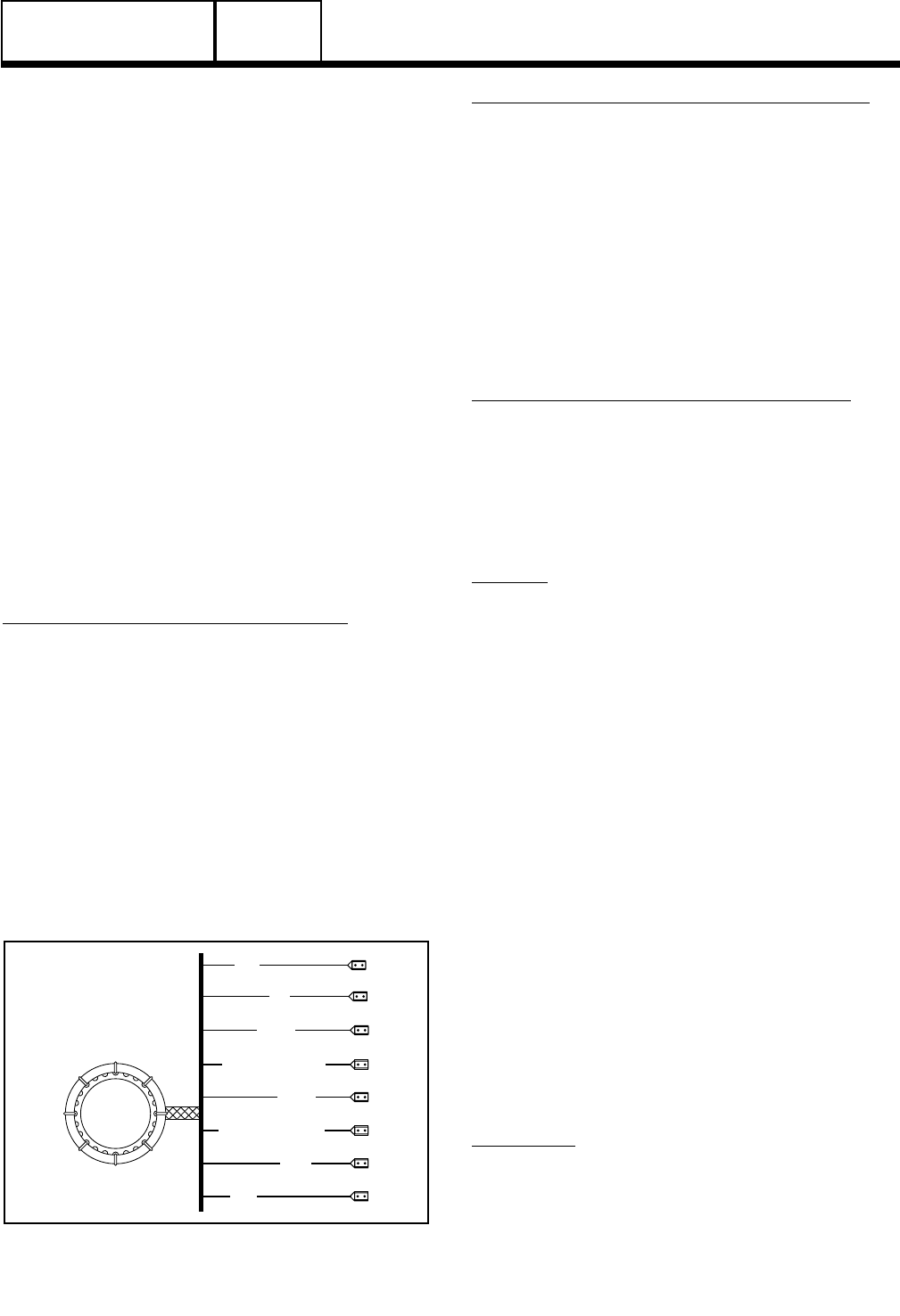

2

6

11P

44

33

22S (12-20 kW)

22P

11S (12-20 kW)

Figure 5. Stator Assembly Leads

TEST FOR A SHORT CIRCUIT BETWEEN WINDINGS:

15. Connect one test lead to stator lead Wire 11 on the load

side of the main circuit breaker. Connect the other test

lead to stator lead Wire 33.

a. The meter should read INFINITY.

b. Any reading other than INFINITY indicates a

short circuit between windings.

16. Repeat Step 15 using stator lead Wire 11; Wire 6.

17. Repeat Step 15 using stator lead Wire 33; Wire 6.

18. Repeat Step 15 using Wire 11 at the voltage regulator;

Wire 6 at the voltage regulator.

TEST CONTROL PANEL WIRES FOR CONTINUITY:

19. Connect one test lead to Wire 11 at the voltage regulator

and the other test lead at stator lead Wire 11

. Continuity

should be measured.

20. Connect one test lead to Wire 22 at the voltage regulator

and the other test lead at stator lead Wire 22

. Continuity

should be measured.

RESULTS:

1. Stator winding resistance values is a test of winding conti-

nuity and resistance. If a very high resistance or INFINITY

is indicated, the winding is open or partially open.

2. Testing for a “grounded” condition: Any resistance

reading indicates the winding is grounded.

3. Testing for a “shorted” condition: Any

resistance

reading

indicates the winding is shorted.

4. If the stator tests good and wire continuity tests good,

perform “Insulation Resistance Test” in Section 1.5.

5. If any test of wire continuity failed in the control panel,

repair or replace the wire, terminal or pin connectors for

that associated wire as needed.

NOTE: Read Section 1.5, “Testing, Cleaning and

Drying” carefully. If the winding tests good, per-

form an insulation resistance test. If the winding

fails the insulation resistance test, clean and dry

the stator as outlined in Section 1.5. Then, repeat

the insulation resistance test. If the winding fails

the second resistance test (after cleaning and

drying), replace the stator assembly.

TEST 8 – TEST BRUSHLESS STATOR

DISCUSSION:

The brushless stator has three internal windings,

two main power windings and a DPE winding. This

test will ensure that there are no shorts between the

power windings or shorts to ground.

A VOM meter can be used to test the stator windings

for the following faults:

PART 2

Page 45