Page 130

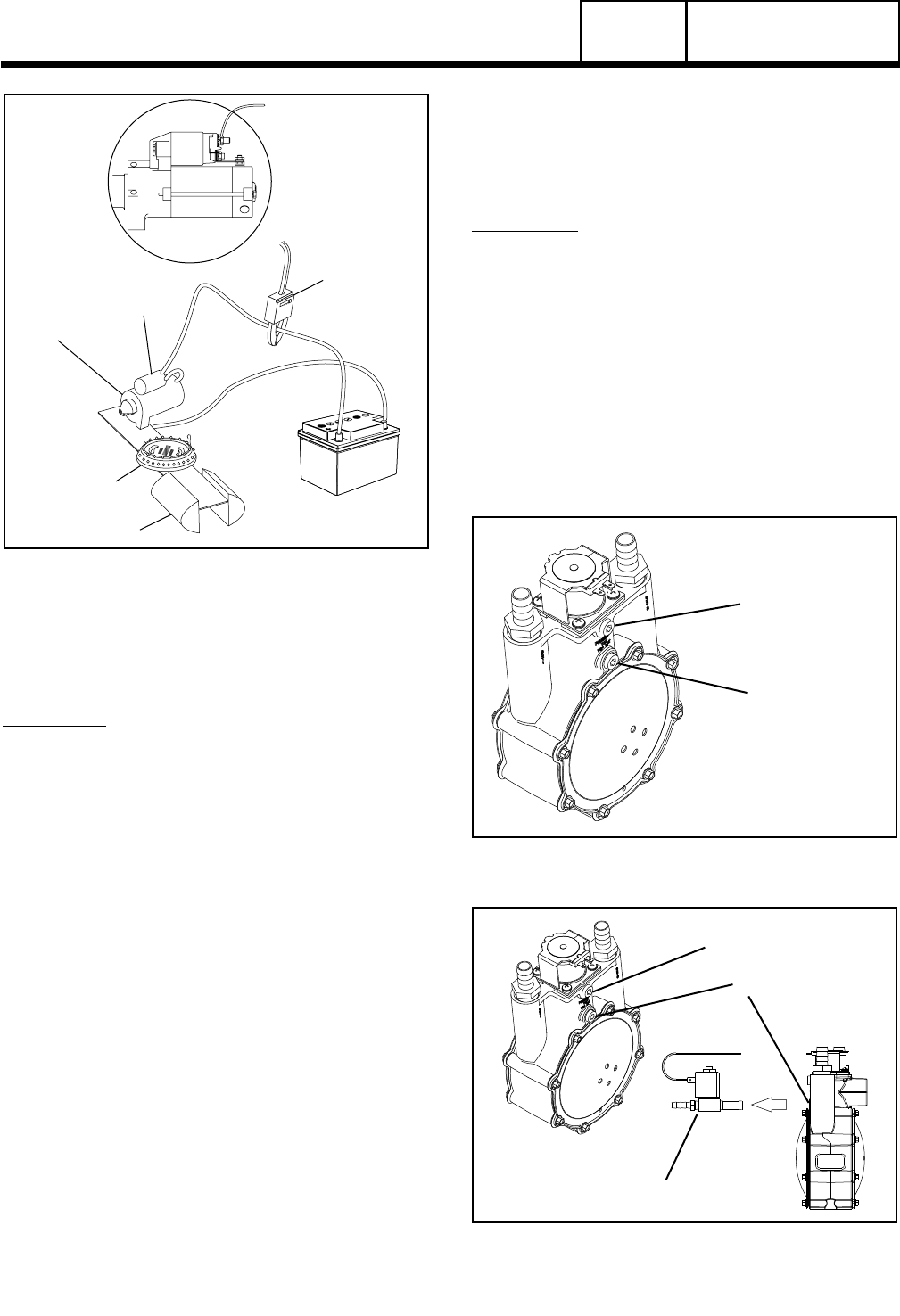

STARTER

CONTACTOR

STARTER

MOTOR

TACHOMETER

12 VOLT

BATTERY

CLAMP ON

AMP METER

VISE

Figure 17. Testing Starter Motor Performance

TEST 66 – CHECK FUEL SUPPLY AND

PRESSURE

DISCUSSION:

The air-cooled generator was factory tested and

adjusted using natural gas as a fuel. If desired, LP

(propane) gas may be used. However, when convert-

ing to propane, some minor adjustments are required.

The following facts apply:

• Anadequategassupplyandsufficientfuelpressure

must be available or the engine will not start.

• Minimum recommended gaseous fuel pressure

at the generator fuel inlet connection is 5 inches

water column for natural gas (NG) or 10 inches

water column for LP gas.

• Maximum gaseous fuel pressure at the generator

fuel inlet connection is 7 inches water column for

natural gas or 12 inches water column for LP gas.

• Whenpropanegasisused,onlya“vaporwithdrawal”

system may be used. This type of system utilizes

the gas that forms above the liquid fuel. The vapor

pressure must be high enough to ensure engine

operation.

• Thegaseousfuelsystemmustbeproperlytestedfor

leaks following installation and periodically thereafter.

No leakage is permitted. Leak test methods must

comply strictly with gas codes.

*

DANGER: GASEOUS FUELS ARE HIGHLY

EXPLOSIVE. DO NOT USE FLAME OR HEAT

TO TEST THE FUEL SYSTEM FOR LEAKS.

NATURAL GAS IS LIGHTER THAN AIR, AND

TENDS TO SETTLE IN HIGH PLACES. LP

(PROPANE) GAS IS HEAVIER THAN AIR, AND

TENDS TO SETTLE IN LOW AREAS. EVEN

THE SLIGHTEST SPARK CAN IGNITE THESE

GASES AND CAUSE AN EXPLOSION.

PROCEDURE:

A water manometer or a gauge that is calibrated in

“ounces per square inch” may be used to measure

the fuel pressure. Fuel pressure at the inlet side of

the fuel solenoid valve should be between 5-7 inches

water column for natural gas (NG) or 10-12 inches

water column for LP gas.

1. See Figures 18, 19 or 20 for the gas pressure test point on

the fuel regulator. The fuel pressure can be checked at Port

1 on all fuel regulators, and at Port 3 on 12-20 kW units.

2. With the manometer connected properly, crank the engine.

Nominal fuel pressure should be measured. If pressure is

not measured while cranking refer back to flow chart.

PORT 1

PORT 2

Figure 18 (8 kW) Gas Pressure Test point

PORT 1

PORT 2

SOLENOID REMOVED

Figure 19 (10 kW) Gas Pressure Test point

PART 4

DC CONTROL

SECTION 4.4

DIAGNOSTIC TESTS