*

DANGER: USE EXTREME CAUTION

DURING THIS TEST. THE GENERATOR WILL

BE RUNNING. HIGH AND DANGEROUS

VOLTAGES WILL BE PRESENT AT THE

TEST TERMINALS. CONNECT METER TEST

CLAMPS TO THE HIGH VOLTAGE TERMINALS

WHILE THE GENERATOR IS SHUT DOWN.

STAY CLEAR OF POWER TERMINALS

DURING THE TEST. MAKE SURE METER

CLAMPS ARE SECURELY ATTACHED AND

WILL NOT SHAKE LOOSE.

PROCEDURE:

1. With the engine shut down, connect the AC voltmeter

test leads across the Wires 11 and 44 terminals of the

generator main circuit breaker (see Figure 1). These

connections will permit line-to-line voltages to be read.

2. Set the generator main circuit breaker to its OFF or

“Open” position. This test will be conducted with the

generator running at no-load.

3. Start the generator, let it stabilize and warm up for a

minute or two.

4. Take the meter reading. On 12-20 kW units the no-load

voltage should be between 249-247 VAC. On 8-10 kW

units the no-load voltage should be between 220-235 VAC.

5. Shut the engine down and remove the meter test leads.

RESULTS:

1. If Step 4 indicated proper voltages, discontinue testing.

2. If any other readings were measured, refer back to flow

chart.

NOTE: “Residual” voltage may be defined as the

voltage that is produced by rotor residual mag-

netism alone. The amount of voltage induced into

the stator AC power windings by residual volt-

age alone will be approximately 2 to 16 volts AC,

depending on the characteristics of the specific

generator. If a unit is supplying residual voltage

only, either excitation current is not reaching the

rotor or the rotor windings are open and the exci-

tation current cannot pass. On current units with

air-cooled engine, “field boost” current flow is

available to the rotor only during engine cranking.

TEST 4 – FIXED EXCITATION TEST/

ROTOR AMP DRAW TEST

DISCUSSION:

Supplying a fixed DC current to the rotor will induce a

magnetic field in the rotor. With the generator running,

this should create a proportional voltage output from

the stator windings.

PROCEDURE:

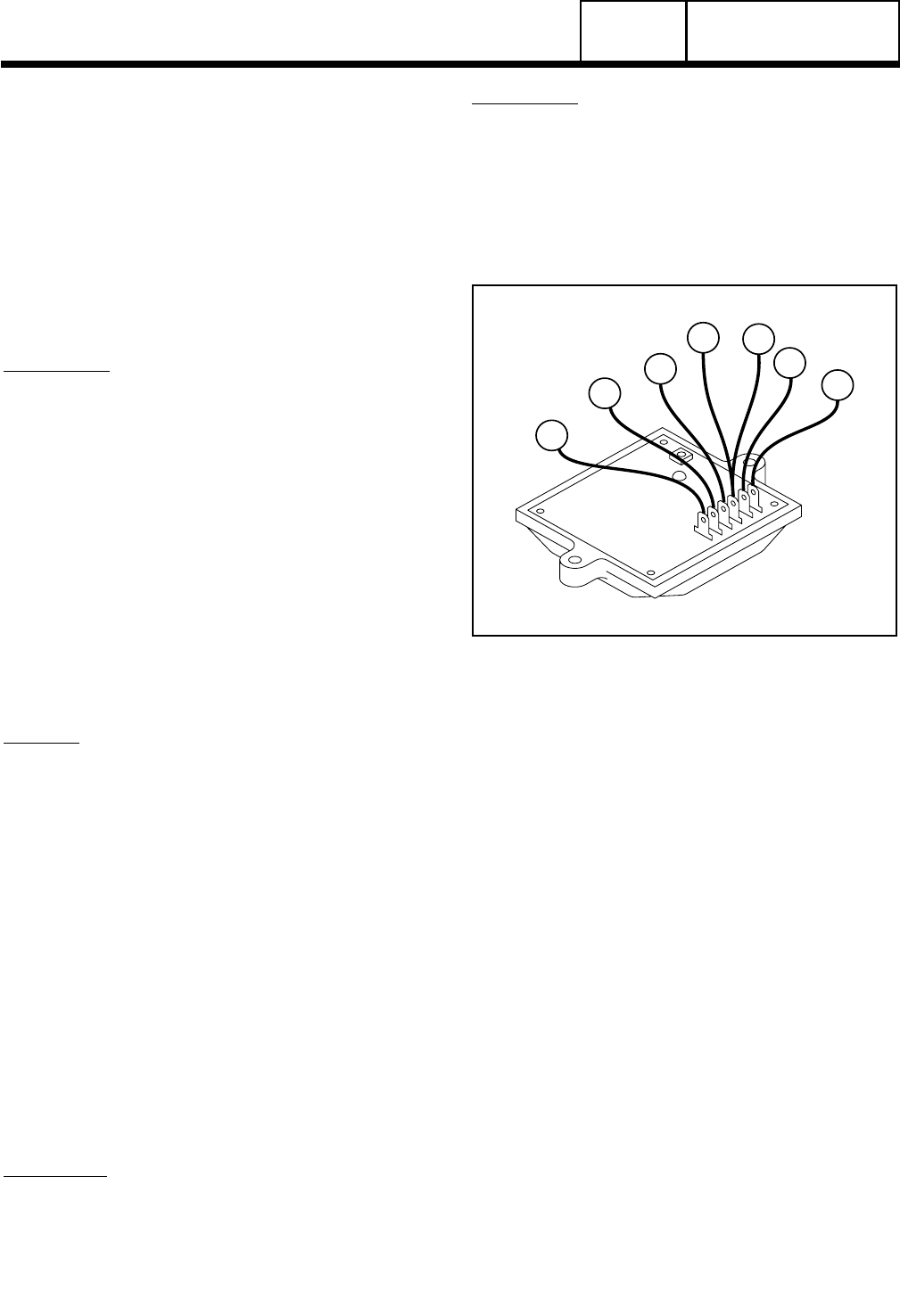

1. Disconnect Wire 4 from the voltage regulator, 3rd

terminal from the top. See Figure 2.

2. Connect a jumper wire to the disconnected Wire 4 and

to the 12 volt fused battery supply Wire 15B (located at

TB1 terminal board).

3. Set VOM to AC volts.

11

22

4

4

0

6

2

Figure 2. Voltage Regulator

4. Disconnect Wire 2 from the voltage regulator and con-

nect one meter test lead to that wire. Disconnect Wire

6 from the voltage regulator and connect the other

meter test lead to that wire. Wires 2 and 6 are located

at the bottom two terminals of the voltage regulator

(see Figure 2).

5. Set the AUTO-OFF-MANUAL switch to MANUAL. Once

the engine starts, record the AC voltage.

6. Set the AUTO-OFF-MANUAL switch to OFF. Reconnect

Wire 2 and Wire 6.

7. Disconnect Wire 11 from the voltage regulator and con-

nect one meter test lead to that wire. Disconnect Wire

22 from the voltage regulator and connect the other

meter test lead to that wire (both wires are located at the

top two terminals of the voltage regulator, see Figure 2).

8. Set the AUTO-OFF-MANUAL switch to MANUAL. Once

the engine starts, record the AC voltage.

9. Set the AUTO-OFF-MANUAL switch to OFF. Reconnect

Wire 11 and Wire 22.

10. Set VOM to DC amperage.

11. Remove jumper lead connected to Wire 4 and Wire 15B.

12. Connect one meter test lead to battery positive 12

VDC supply Wire 15B, located at TB1 terminal board.

Page 42

PART 2

AC GENERATORS

SECTION 2.4

DIAGNOSTIC TESTS