SECTION 4.4

DIAGNOSTIC TESTS

Page 129

PINION

Figure 13. Check Pinion Gear Operation

(Single Cylinder)

TOOLS FOR STARTER PERFORMANCE TEST:

The following equipment may be used to complete a

performance test of the starter motor:

• Aclamp-onammeter.

• Atachometercapableofreadingupto10,000rpm.

• Afullycharged12voltbattery.

MEASURING CURRENT:

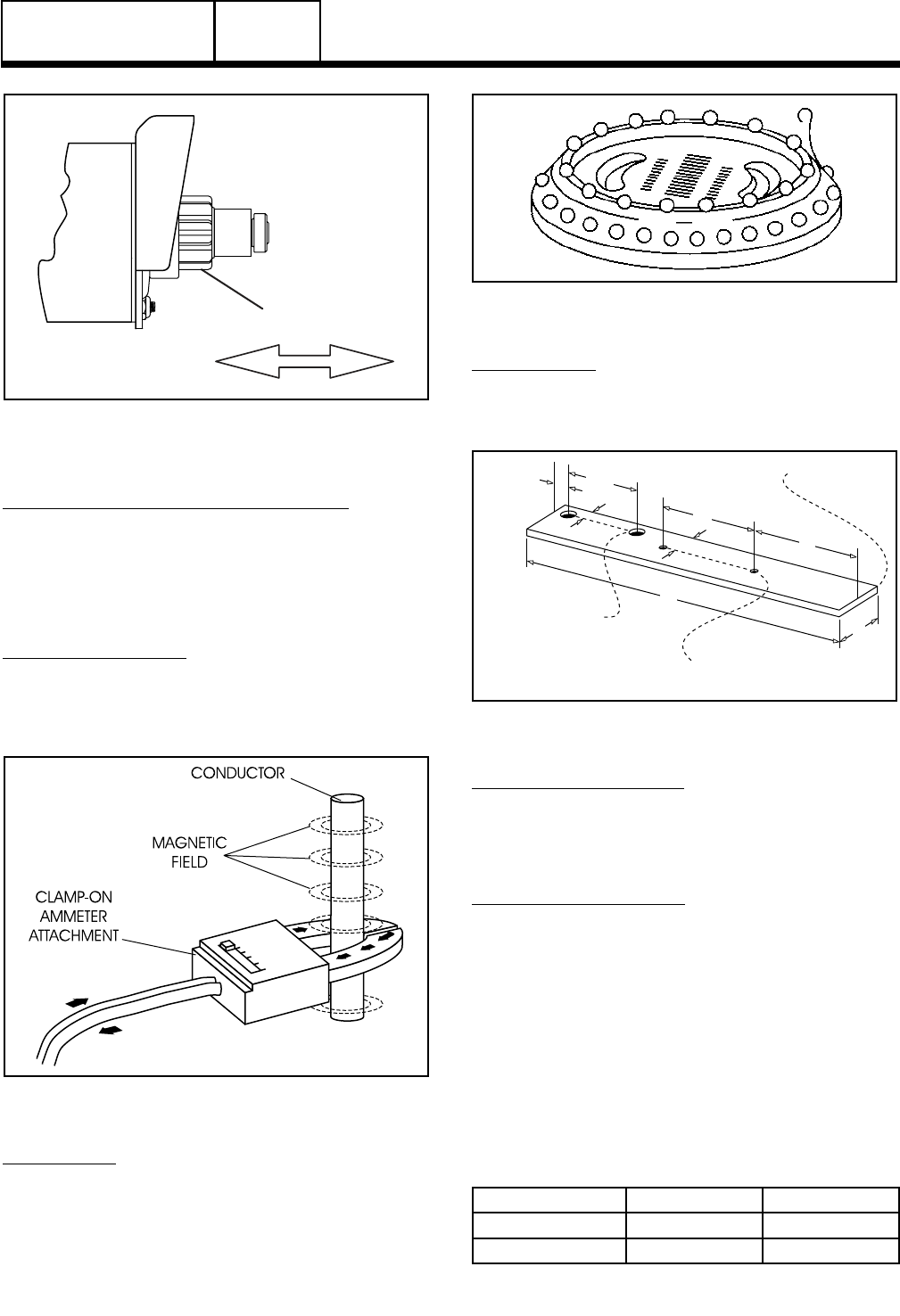

To read the current flow, in AMPERES, a clamp-on

ammeter may be used. This type of meter indicates

current flow through a conductor by measuring the

strength of the magnetic field around that conductor.

Figure 14. Clamp-On Ammeter

TACHOMETER:

A tachometer is available from your parts source.

The tachometer measures from 800 to 50,000 rpm,

(see Figure 15).

Figure 15. Tachometer

TEST BRACKET:

A starter motor test bracket may be made as shown

in Figure 16. A growler or armature tester is available

from an automobile diagnostic service supplier.

METAL STOCK

1/4" THICK STEEL

12"

1.0"

4"

2"

2.625"

3.5"

0.5"

0.5"

DRILL TWO HOLES — 1/2"

FOR STARTER

MOUNTING BRACKET

DRILL TWO HOLES — 1/2"

FOR MOUNTING TACHOMETER

TAP FOR 1/4-20 NC SCREWS

Figure 16. Test Bracket

REMOVE STARTER MOTOR:

It is recommended that the starter motor be removed

from the engine when testing starter motor perfor-

mance. Assemble starter to test bracket and clamp

test bracket in vise, Figure 17.

TESTING STARTER MOTOR:

1. A fully charged 12 volt battery is required.

2. Connect jumper cables and clamp-on ammeter as

shown in Figure 17.

3. With the starter motor activated (jump the terminal on the

starter contactor to battery voltage), note the reading on

the clamp-on ammeter and on the tachometer (rpm).

Note: Take the reading after the ammeter and

tachometer are stabilized, approximately 2-4

seconds.

4. A starter motor in good condition will be within the fol-

lowing specifications:

V-twin Single Cylinder

Minimum rpm 3250 4500

Maximum Amps 62 9

DC CONTROL

PART 4