"C"

"B"

"C"

ROTOR

"B"

"C"

9

"D"

"B"

"C"

"D"

BEARING CARRIER

BRUSH HOLDER

ASSEMBLY

ENGINE ADAPTOR

"8KW"

"8KW - 10KW"

ENGINE ADAPTOR

"10KW"

0.8

"D"

"D"

STATOR

"12KW - 20KW"

"12KW - 20KW"

INTRODUCTION

The air-cooled, automatic standby system is an easy

to install, fully enclosed and self-sufficient electric

power system. It is designed especially for homeown-

ers, but may be used in other applications as well.

On occurrence of a utility power failure, this high

performance system will (a) crank and start automati-

cally, and (b) automatically transfer electrical loads to

generator AC output.

The generator revolving field (rotor) is driven by an

air-cooled engine at about 3600 rpm.

The generator may be used to supply electrical power

for the operation of 120 and/or 240 volts, 1-phase, 60

Hz, AC loads.

A 2-pole, “W/V-Type” transfer switch is offered (see

Part 3). The transfer switch does not include an “intel-

ligence circuit” of it’s own. Instead, automatic startup,

transfer, running, retransfer and shutdown operations

are controlled by a solid state circuit board in the

generator control panel.

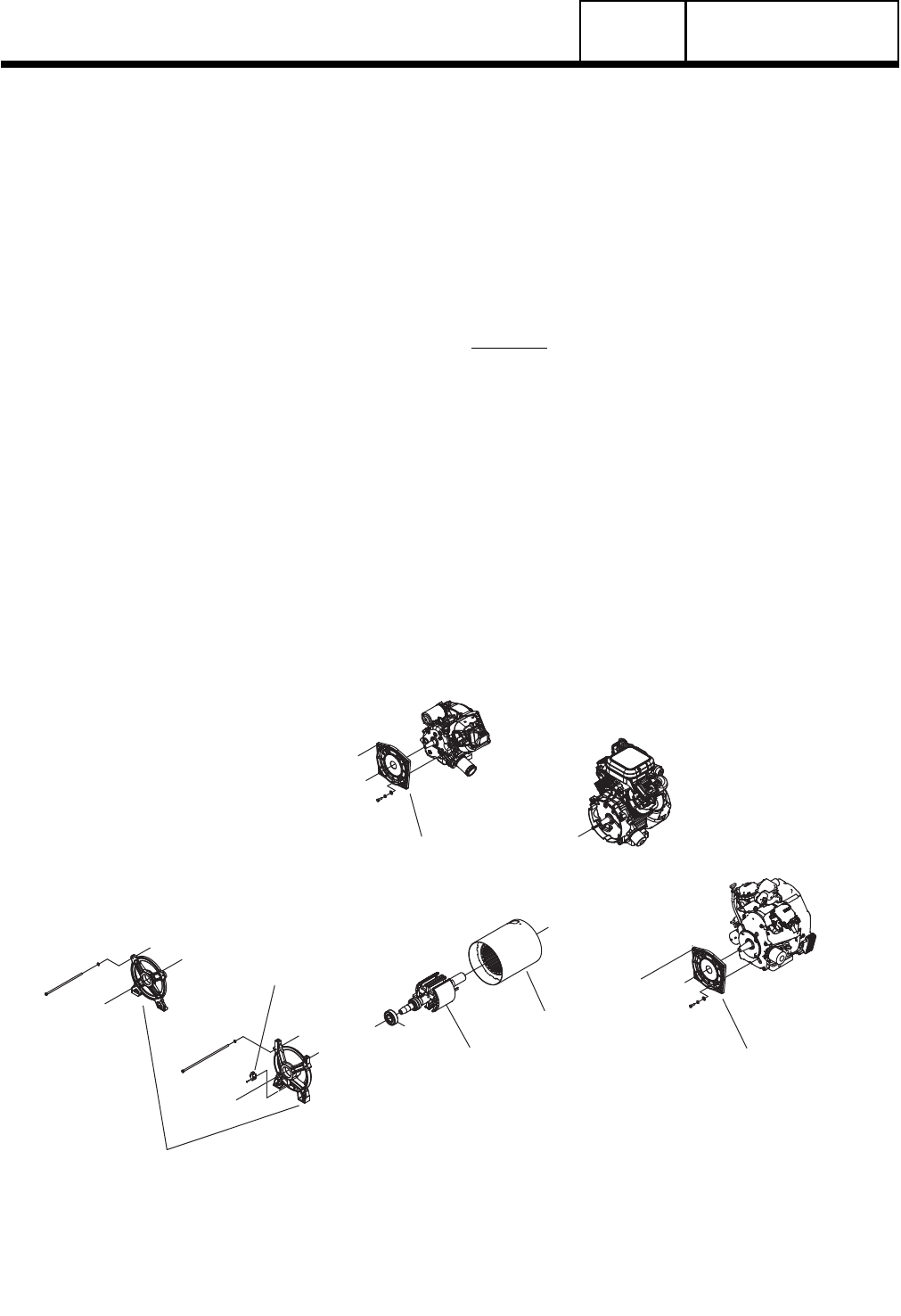

ENGINE-GENERATOR DRIVE SYSTEM

The generator revolving field is driven by an air-

cooled, horizontal crankshaft engine. The generator is

directly coupled to the engine crankshaft (see Figure

1), and mounted in an enclosure. Both the engine and

generator rotor are driven at approximately 3600 rpm,

to provide a 60 Hz AC output.

THE AC GENERATOR

Figure 1 shows the major components of the AC

generator.

ROTOR ASSEMBLY

12-20 KW:

The 2-pole rotor must be operated at 3600 rpm to

supply a 60 Hertz AC frequency. The term “2-pole”

means the rotor has a single north magnetic pole and

a single south magnetic pole. As the rotor rotates, its

lines of magnetic flux cut across the stator assem-

bly windings and a voltage is induced into the stator

windings. The rotor shaft mounts a positive (+) and

a negative (-) slip ring, with the positive (+) slip ring

nearest the rear bearing carrier. The rotor bearing is

pressed onto the end of the rotor shaft. The tapered

rotor shaft is mounted to a tapered crankshaft and is

held in place with a single through bolt.

Figure 1. AC Generator Exploded View

PART 2

Page 32

AC GENERATORS

SECTION 2.1

DESCRIPTION & COMPONENTS