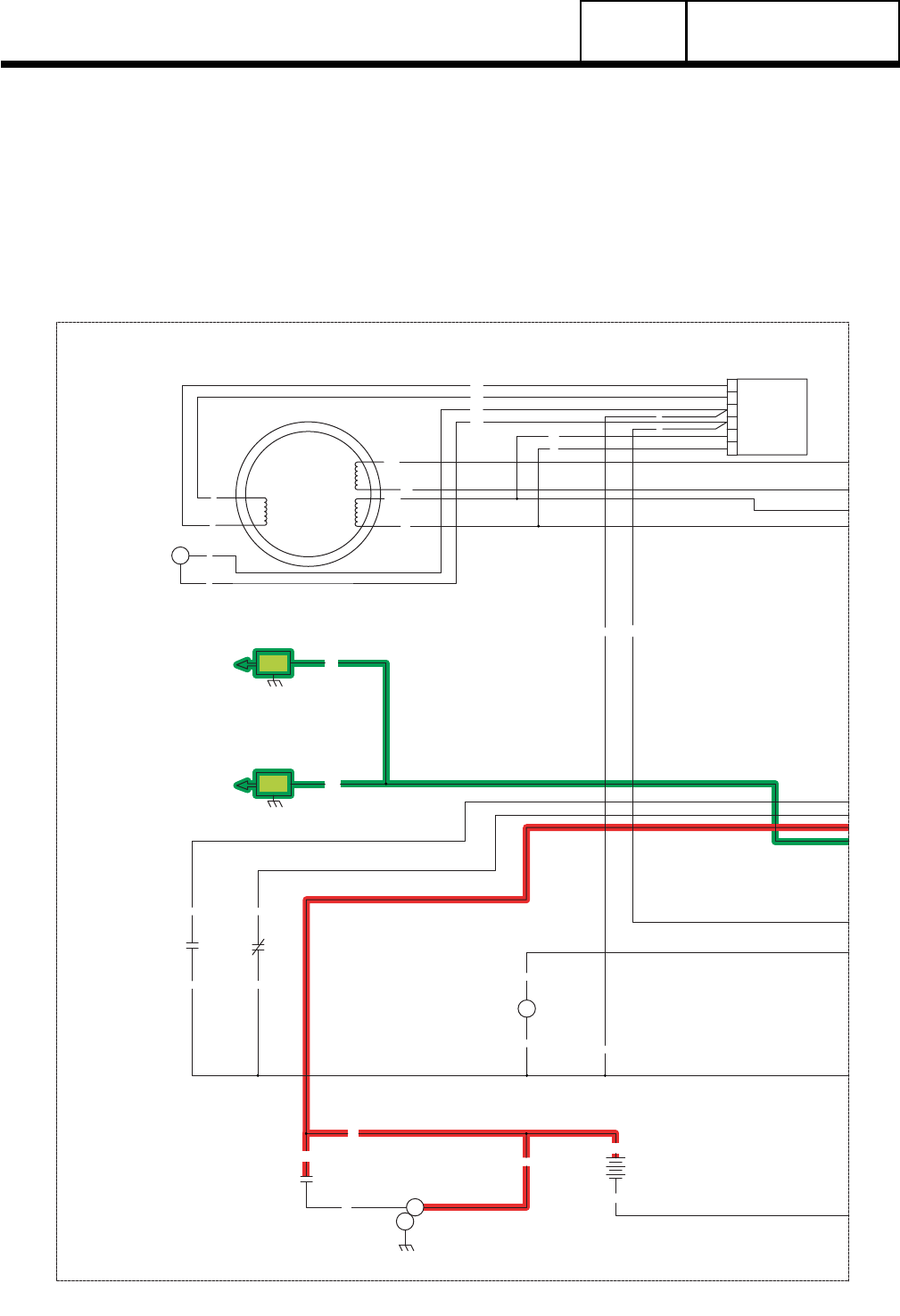

CONTROLLER DISPLAY

Ready to Run

= 12 VDC ALWAYS PRESENT

= AC VOLTAGE

= GROUND FOR CONTROL PURPOSES

= 12 VDC DURING CRANKING ONLY

= 12 VDC DURING ENGINE RUN CONDITION

= DC FIELD EXCITATION

= 5 VDC TO LED

0

4

4

0

BA

6

11

22

6

2

2

REGULATOR

11

2

6

0

4

22

VOLTAGE

4

0

0

13

13

18

SP2

IM2

16

13

SCR

0

0

86

85

HTO

LOP

18

0

13

12V

BATTERY

SCR

SM

IM1

SP1

44

11

POWER

WINDING

33

22

WINDING

POWER

STATOR

4

0

56

0

SC

820

817

818

819

819

818

817

820

L2

L1

LED BOARD

4

3

2

1

4

ACTUATOR

GOVERNOR

14

14

90

OUTPUT

GENERATOR

240 VAC

NEUTRAL

INPUT

UTILITY

240 VAC

TRANSFER

+ BATTERY

GROUND

56015B23

23

0

0

FS

BATTERY WARMER

OPTIONAL

N1

00

22

33

11

44

CB

15B

14

0

0

CS

N2

N1

21

N2

N1

18

13

86

85

4

3

2

1

18171615141312109 1186 743 5

CB - CIRCUIT BREAKER, MAIN OUTPUT

HTO - HIGH TEMPERATURE SWITCH

FS - FUEL SOLENOID

LEGEND

SCR - STARTER CONTROL RELAY

SC - STARTER CONTACTOR

CS - CHOKE SOLENOID

LOP - LOW OIL PRESSURE SWITCH

SM - STARTER MOTOR

BA - BRUSH ASSEMBLY

IM_ - IGNITION MODULE

SP_ - SPARK PLUG

0

J3

J1

PRINTED CIRCUIT BOARD

TO

PCB

7.5 AMP FUSE

SELF RESETTING FUSE

CONTROLLER

J2

Page 104

INTRODUCTION

This “Operational Analysis” is intended to familiarize the service technician with the operation of the DC control

system on units with air-cooled engine. A thorough understanding of how the system works is essential to sound

and logical troubleshooting. The DC control system illustrations on the following pages represent a 14 kW unit.

UTILITY SOURCE VOLTAGE AVAILABLE

See Figure 1, below. The circuit condition with the AUTO-OFF-MANUAL switch set to AUTO and with “Utility”

source power available can be briefly described as follows:

PART 4

DC CONTROL

SECTION 4.2

OPERATIONAL ANALYSIS