Groundsmaster 3505--D Hydraulic SystemPage 4 -- 55

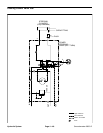

Hydraulic Tank Removal (Fig. 33)

1. Drain hydraulic oil from Hydraulic tank (see Traction

Unit Operator’s Manual).

2. Thoroughly clean hydraulichose ends and fittingson

hydraulic tank to prevent hydraulic system contamina-

tion.

3. Remove hydraulic tank using Figure 33 as a guide.

Discard and replace any o--rings that are removed.

Hydraulic Tank Inspection (Fig. 33)

1. Clean hydraulic tank and suction strainer with sol-

vent.

2. Inspecthydraulic tank for leaks, cracksor other dam-

age.

Hydraulic Tank Installation (Fig. 33)

1. Apply antiseize lubricant to the four (4) flange head

screws that secure the hydraulic tank to the frame.

2. Position hydraulic tank to machine. Secure tank to

frame with four (4) flange head screws, flat washers and

grommets. Torque screws from 30 to 60 in--lb ( 3.4 to 6.8

N--m).

3. Attach fittings withnew o--rings and hoses to hydrau-

lic tank using Figure 33 as a guide.

4. Thread suction strainer into hydraulic tank.

5. Using a wrench, turn strainer into tank port 1--1/2 to

2 full turns beyond finger tight.

6. Fill hydraulic tank with new hydraulic fluid (see Trac-

tion Unit Operator’s Manual).

7. Operate machine. Check hydraulic oil level and ad-

just ifnecessary.Check hydrauliccomponents forleaks.

Tighten any loose connections.

Hydraulic

System