Rev. A

Groundsmaster 3505--D Page 6 -- 15 Chassis

Disassembly (Fig. 9)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Remove philips head screw and steering wheel cap

from the steering wheel.

3. Remove steering wheel nut from the steering control

valve. Pull steering wheel from the steering control

valve.

4. Remove steering cover (item 7) from the steering

control valve bracket.

5. Remove four (4) flange head screws securing the

steering control valve to the steering control valve

bracket.

6. Removeboth flange nuts,cap screws andpivot hubs

securing the steering control valve bracket to the steer-

ing arm. Slide bracket from the steering control valve

and steering arm.

7. Remove remaining parts as necessary to repair

steering column using Figure 9 as a guide. If steering

control valve requires service, see Steering Control

Valve in the Service and Repairs section of Chapter 4 --

Hydraulic System.

Assembly (Fig. 9)

1. Make sure lever and friction discs are properly as-

sembled to the steering control valve bracket using Fig-

ures 9 and 10 as guides.

2. Position steering control bracket to the steering con-

trol valve and steering arm. Secure bracket to the steer-

ing arm with pivot hubs, cap screws and flange nuts.

3. Secure steering control valve bracket to the steering

control valve with four (4) flange head screws.

4. Secure steering cover to the steering control valve

bracket with washer head screws.

5. Install steering wheel to the steering control valve.

Torque steering wheel nut from 20 to 26 ft--lb (28 to 35

N--m).

6. Secure steering wheel cap to thesteering wheelwith

philips head screw.

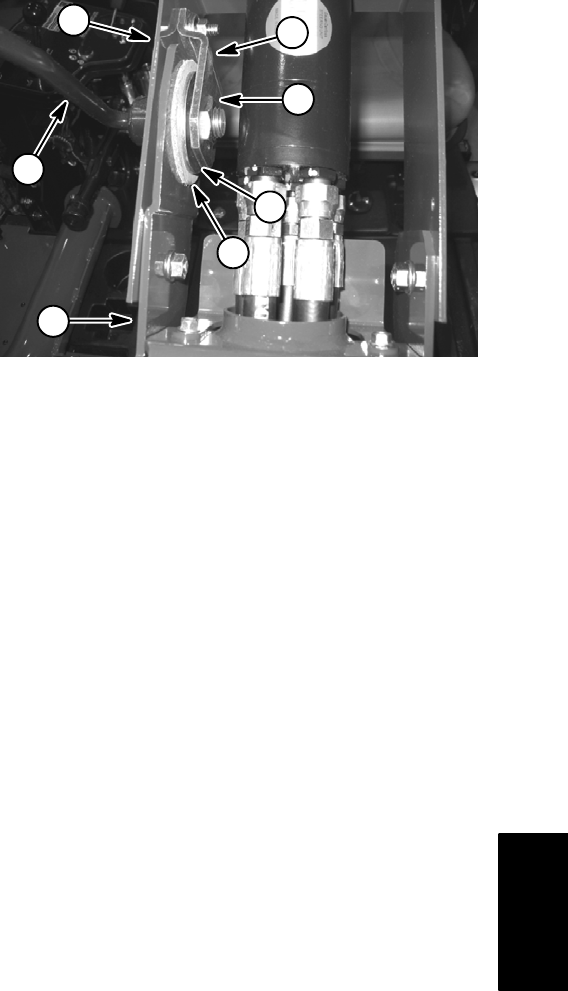

1. Tilt bracket

2. Steering valve bracket

3. Jam nut

4. Flat washer

5. Friction disc

6. Steering tilt lever

7. Steering arm

Figure 10

1

3

4

5

7

6

2

Chassis