Groundsmaster 3505--D Hydraulic SystemPage 4 -- 27

Procedure for Traction Circuit Working Pressure

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature. Park machine on a level surface with the cut-

ting units lowered and off. Make sure engine is off.

2. Read Precautions for Hydraulic Testing.

3. Make sure that traction pedal is adjusted to the neu-

tral position (see Traction Unit Operator ’s Manual).

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor -

mation section.

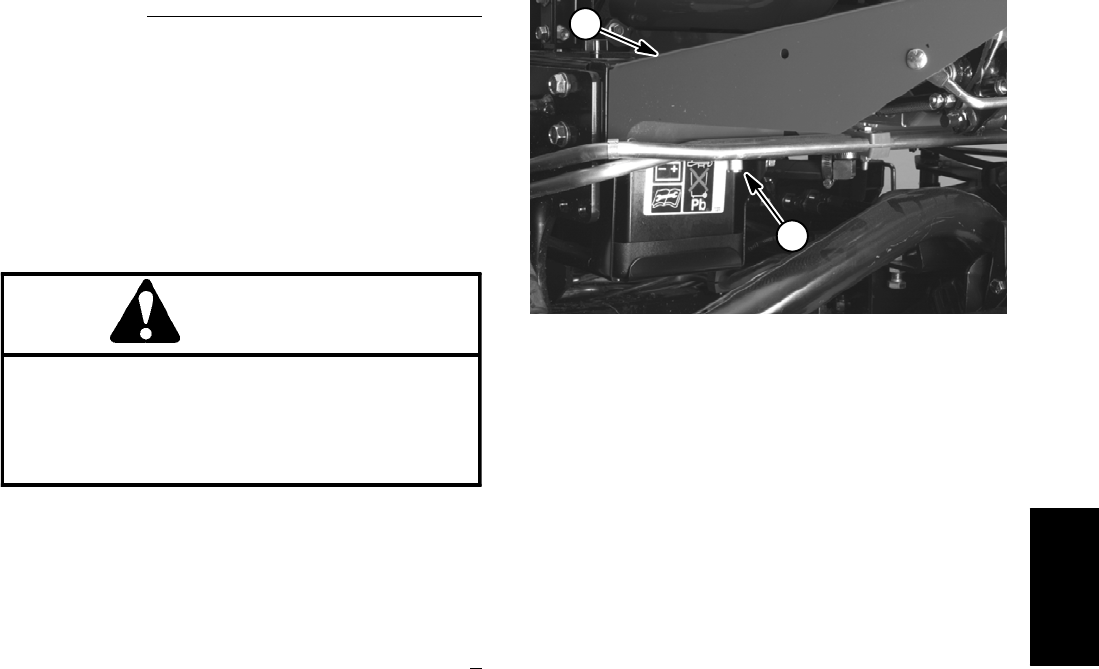

4. Remove plug from hydraulic tube connected to front

wheel motors (Fig. 16). Connect test gauge with an at-

tached hydraulic hose to the hydraulic tube opening.

Make sure hoseis long enough sothe operator can read

gauge while driving the machine.

5. Start engine and move throttle to full speed (3050 +

50 RPM).

6. Drivemachine in theforward direction. Observe test

gauge:

A. Pressure while transporting the machine over a

flat, level surface should be about 500 PSI.

B. Pressure driving the machine up a hill should be

about 2500 PSI but can reach relief settings (3000

PSI).

C. Pressure while mowing should range between

1000 to 2000 PSI and will vary with terrain condi-

tions.

7. Release traction pedal and turn off machine. Record

test results.

8. If specification is not met, the hydrostat needs to be

repaired or replaced as necessary.

9. Relieve hydraulic system pressure (See Relieving

Hydraulic System Pressure in the General Information

section). Disconnect test gauge and hose from the hy-

draulic tube. Install plug into tube opening.

1. Hydraulic tube with plug 2. Floor plate

Figure 16

1

2

Hydraulic

System