Groundsmaster 3505--DPage 6 -- 8Chassis

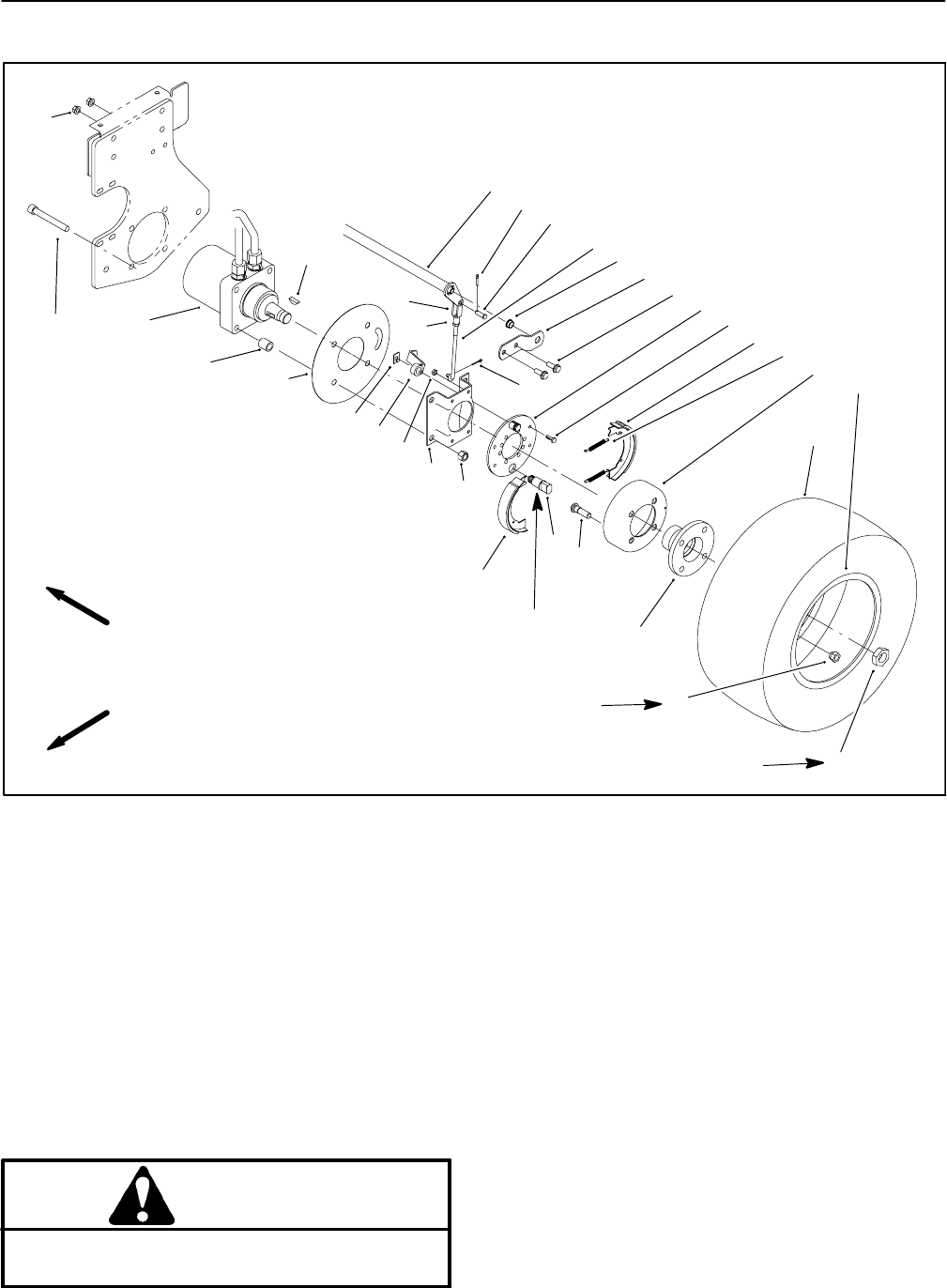

Front Wheels and Brakes

1. Lug nut (4 used per wheel)

2. Drive stud (4 used per wheel)

3. Wheel rim

4. Tire

5. Wheel hub

6. Lock nut

7. Hydraulic wheel motor

8. Brake drum

9. Woodruff key

10. Cotter pin

11. Adjustment rod

12. Brake lever

13. Lock nut (4 used per wheel)

14. Cap screw (4 used per wheel)

15. Brake bracket

16. Return spring (2 used per wheel)

17. Brake shoe (2 used per wheel)

18. Backing plate

19. Cam shaft

20. Retainer clip

21. Lock nut (4 used per wheel)

22. Socket head screw (4 used per wheel)

23. Spacer (4 used per wheel)

24. Wheel shield

25. Cotter pin

26. Clevis pin

27. Clevis

28. Jam nut

29. Flange bushing

30. Brake pivot bracket

31. Brake pivot shaft

32. Flange head screw (2 per wheel)

33. Flange nut (2 per wheel)

Figure 5

FRONT

RIGHT

250 to 350 ft--lb

(339 to 474 N--m)

45 to 65 ft--lb

(61to88N--m)

10

28

31

30

32

29

3

8

2

6

4

1

14

13

24

12

27

26

25

11

15

21

5

18

19

20

16

17

17

7

23

22

33

9

Antiseize

Lubricant

Removal (Fig. 5)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

WARNING

Before jacking upthe machine, reviewand follow

Jacking Instructions in Chapter 1 -- Safety.

2. Jack up front wheel and use jack stands or blocking

to keep the front tire off the floor.

3. Remove lug nuts from drive studs. Pull wheel from

drive studs and wheel hub.

NOTE: The installation torque of the lock nut is from

250 to 350 ft--lb (339 to 474 N--m). Use impact wrench

to remove lock nut from the hydraulic motor shaft.

4. Remove lock nut from the hydraulic motor shaft. Re-

lease parking brake.