Groundsmaster 3505--DPage 5 -- 14Electrical System

Neutral Switch

The neutral switch is a proximity type, normally open

reed switch that closes when the traction pedal is in the

neutral position. The neutral switch is located under the

floor support plate (Fig. 15).

The Standard Control Module monitors the operation of

the neutral switch. If the ignition switch is in the ON posi-

tion and the traction pedal is in the neutral position, the

Module Neutral input LED should be illuminated.

Testing

1. Make sure ignition switch is in the OFF position. Dis-

connect electrical connector from the neutral switch.

2. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the connector termi-

nals.

3. With the traction pedal in the neutral position, there

should be continuity between the two switch leads.

4. Slowlydepress the tractionpedal. Thecontinuity tes-

ter should show no continuity as the pedal is moved in

either the forward or reverse direction.

5. Reconnect switch after testing.

6. Switch adjustment: neutral switch should be

installed so that the pin on the traction pedal (neutral

position) is centered with the switch when the pedal is

in the neutral position.

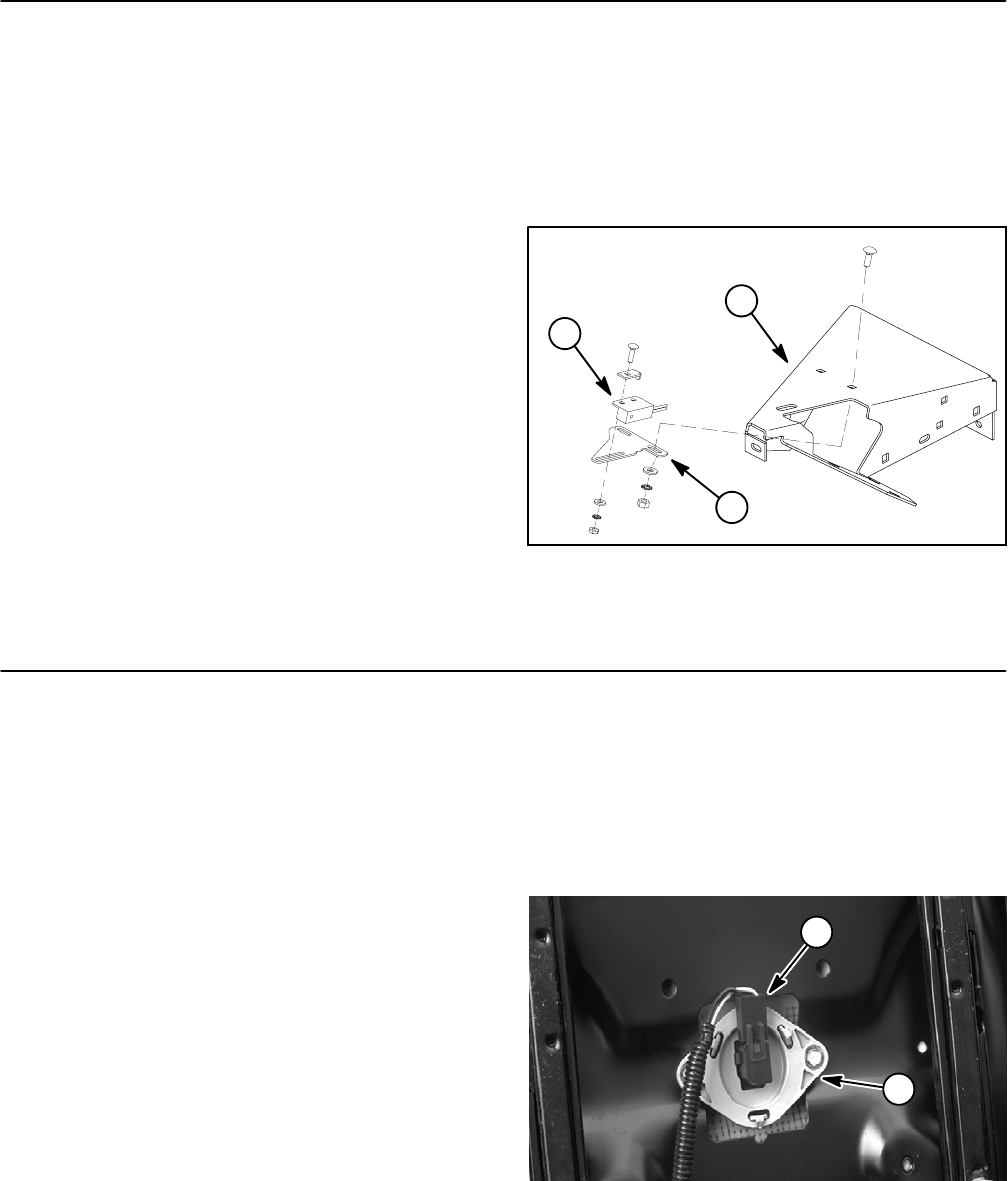

1. Neutral switch

2. Floor support plate

3. Switch bracket

Figure 15

2

1

3

Seat Switch

The seat switch is normally open and closes when the

operator is on the seat. If the traction system or PTO

switch is engaged when the operator raises out of the

seat, the engine will stop. The seat switch (Fig. 16) and

its electrical connector are located directly under the

seat.

The Standard Control Module monitors the operation of

the seat switch. If the ignition switch is in the ON position

and the seat is occupied, the Module in seat input LED

should be illuminated.

Testing

1. Make sure ignition switch is in the OFF position. Re-

move seat (see Operator Seat in Service and Repairs

section of Chapter 6 -- Chassis).

2. Disconnect electrical connector from the switch.

3. Check the continuity of the switch by connecting a

multimeter (ohms setting) across the connector termi-

nals.

4. With no pressure on the seat, there should be no

continuity between the seat switch terminals.

5. Press directly onto the seat switch through the seat

cushion. There should be continuity as the seat cushion

approaches the bottom of its travel.

6. Reconnect seat switch connector. Reinstall seat as-

sembly.

1. Seat switch 2. Electrical connector

Figure 16

2

1