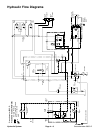

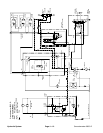

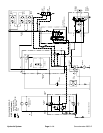

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 15

Lift Circuit (Lower)

Circuit operation for lowering the cutting units is similar

to raising them. However, pressure is relieved from the

lift cylinders and this action allows the cutting units to

lower.

During conditions of not lifting or lowering cutting units,

flow from gear pump (P2) is by--passed through the

steering control valve, lift control valve and hydraulic

manifold directly to the hydrostat (charge). Flow then re-

turns to gear pump (P1) inlet.

When the cutting units are to be lowered, the lift control

valve is positioned by moving the lift control lever to

LOWER. Pressure from gear pump (P2) is used to shift

the pilot valvein the control valve.This shifted pilot valve

allows hydraulic pressure to relieve from the cap end of

the lift cylinders. Flow from the cap end of the lift cylin-

ders causes the cutting units to lower. At the same time,

the fluid relieved from the cap end of the lift cylinders

goes into the rod end of the cylinders and back through

the hydraulic manifold block to the hydrostat (charge).

When the lift control lever is released, spring action re-

turns the valve to its original position and by--passes

flow back to the hydrostat (charge). The pilot valve re-

mains shifted to allow the lift cylinders to float until the

lift control valve is moved to the raise position.

The logic cartridge valve (LC1) in the manifold block

maintains 250 PSI (17.2 bar) back pressure on the lift

cylinders. This counterbalance pressure transfers cut-

ting unit weight to the machine to improve traction.

Hydraulic

System