Groundsmaster 3505--D Page 6 -- 17 Chassis

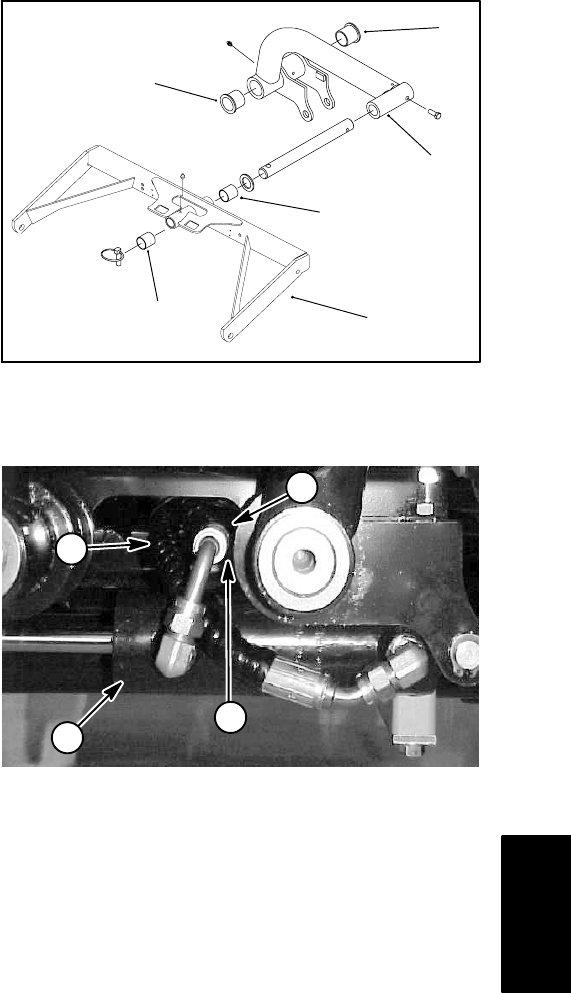

Removal (Fig. 11)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Remove cutting units from the pivot shaft of the front

lift arms (see Cutting Unit Operator’s Manual).

NOTE: Remove both spacers from the hydraulic cylin-

der shaft clevis when removing the right, front lift arm.

3. Disconnect hydraulic cylinder from the front lift arms

by removing external retaining rings and pins.

4. Remove both flange head screws and carrier stop

bracket from the lift arm pivot shafts.

5. Slide lift arm off the pivot shaft.

6. Disassemble lift arm as necessary using Figure 11

as a guide.

7. Inspect bushings in lift arm and carrier frame (Fig

12). If bushings are worn or damaged, replace bush-

ings.

Installation (Fig. 11)

1. Assemble lift arm using Figure 11 as a guide.

A. If clamps (item 20) were removed, torque cap

screws (item 20) from 55 to 65 ft--lb (75 to 88 N--m).

B. Ifcarrier frame pivotshaft (item40) was removed,

apply antiseize lubricant to pivot shaft before instal-

ling carrier frame.

2. Slide lift arm onto the lift arm pivot shaft.

3. Secure carrier stop bracket with both flange head

screws to the lift arm pivot shafts.

NOTE: Install both spacers to the hydraulic cylinder

shaft clevis when installing the right, front lift arm.

4. Secure hydraulic cylinder to the lift arm with pins and

external retaining rings.

5. Route hydraulic hoses so they clear the lift arm by

0.040” to 0.120” (1.0 to 3.0 mm) when the lift arm is fully

raised (Fig. 13).

6. Adjust lift arms for proper clearance (see Traction

Unit Operator’s Manual).

7. Install cutting unit to the front lift arm pivot shaft (see

Cutting Unit Operator’s Manual).

8. Grease front lift arms (see Traction Unit Operator’s

Manual).

1. Carrier frame

2. Front lift arm (LH shown)

3. Lift arm bushing

4. Frame bushing

Figure 12

2

4

1

3

3

4

1. Hydraulic hose

2. Hydraulic cylinder

3. Clearance

Figure 13

1

3

2

1

Chassis