Rev. A

Groundsmaster 3505--DPage 7 -- 12Cutting Units

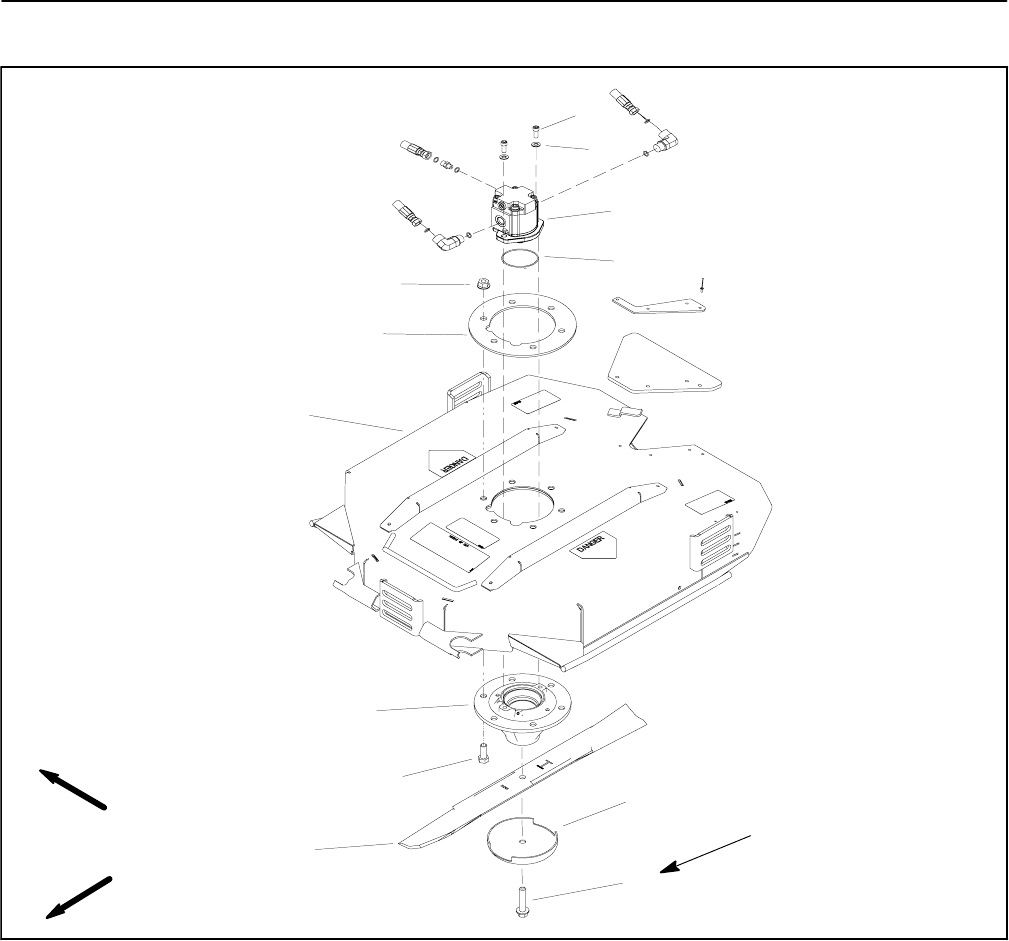

Blade Spindle

1. Socket head screw (2 per motor)

2. Flat washer (2 per motor)

3. Hydraulic deck motor

4. O--ring

5. Flange nut (6 used)

6. Spindle plate

7. Cutting deck

8. Spindle assembly

9. Cap screw (6 used)

10. Cutting blade

11. Anti--scalp cup

12. Blade bolt

Figure 13

FRONT

RIGHT

6

11

8

9

7

12

10

3

5

4

2

1

88 to 108 ft--lb

(119 to 146 N--m)

Removal (Fig. 13)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Remove two (2) socket head screws and flat wash-

ers that secure hydraulic motor to the cutting unit ( Fig.

14). Remove hydraulic motor from deck. Locate and re-

trieve o--ring from top of spindle housing.

3. Cover top of spindle to prevent contamination.

Spindle plug (ToroPart # 94--2703) can be used to cover

spindle.

4. Start the engine and raise the cutting unit. Stop en-

gine and remove key from the ignition switch. Support

the cuttingunit so itcannot lower accidentally.If required

for easier service, remove cutting unit from machine

(see Cutting Unit Operator’s Manual).

5. Remove cutting blade bolt, anti--scalp cup and cut-

ting blade (see Cutting Unit Operator’s Manual).

6. Remove six ( 6) cap screws and flange nuts securing

spindle housing to deck. Lower spindle assembly out

the bottom of the deck. Remove spindle plate from top

of deck.