Groundsmaster 3505--D Hydraulic SystemPage 4 -- 45

Procedure for Steering and Lift Relief Pressure

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature.

2. Park machine on a levelsurface with the cuttingunits

lowered and off. Make sure engine is off and the parking

brake is engaged.

3. Read Precautions for Hydraulic Testing.

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor -

mation section.

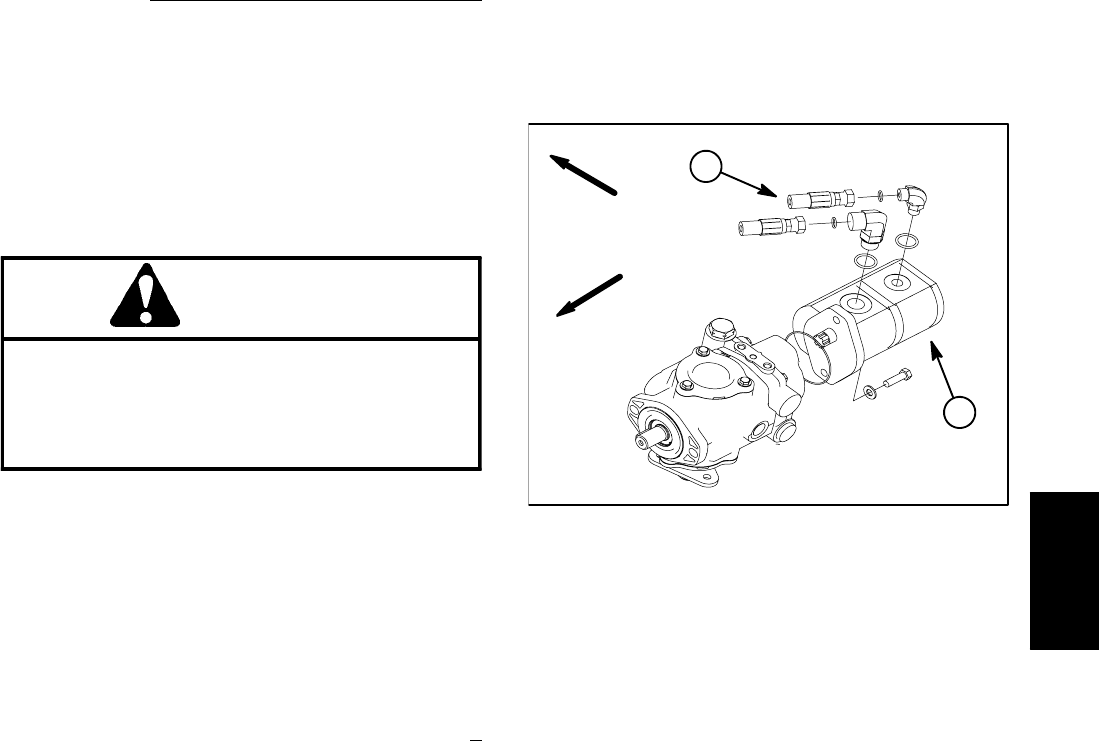

4. Disconnect hose connection on gear pump (P2)

leading to the steering control valve (Fig. 30).

5. Install T-- connector with hydraulic pressure gauge in

series with the discharge of the gear pump and the dis-

connected hose leading to the steering control valve.

6. Make sure steering wheel is positioned so the rear

wheel points directly ahead.

7. Start engine and move throttle to full speed (3050 +

50 RPM).

IMPORTANT: Do not allow pressure to exceed 1500

PSI.

IMPORTANT: Hold steering wheel at full lock only

long enough to get a system pressure reading.

Holding the steering wheel against t he stop for an

extended period may damage the steering control

valve.

8. Watch pressure gauge carefully while turning the

steering wheel completely in one direction and holding.

9. System pressure should be from 845 to 995 PSI as

the relief valve lifts. Return steering wheel to the center

position.

10.Shut off engine. Record test results.

11.If specification is not met, repair or replace steering

control valve (relief valve in steering control valve is not

replaceable).

12.Relieve hydraulic system pressure (See Relieving

Hydraulic System Pressure in the General Information

section). Disconnect T--connector with test gauge from

pump connection and hose. Reconnect hydraulic hose

to gear pump (P2).

1. Gear pump (P2) 2. To steering control valve

Figure 30

FRONT

RIGHT

1

2

Hydraulic

System