Groundsmaster 4100--D/4110--D Hydraulic SystemPage 4 -- 25

Engine Cooling Fan Circuit

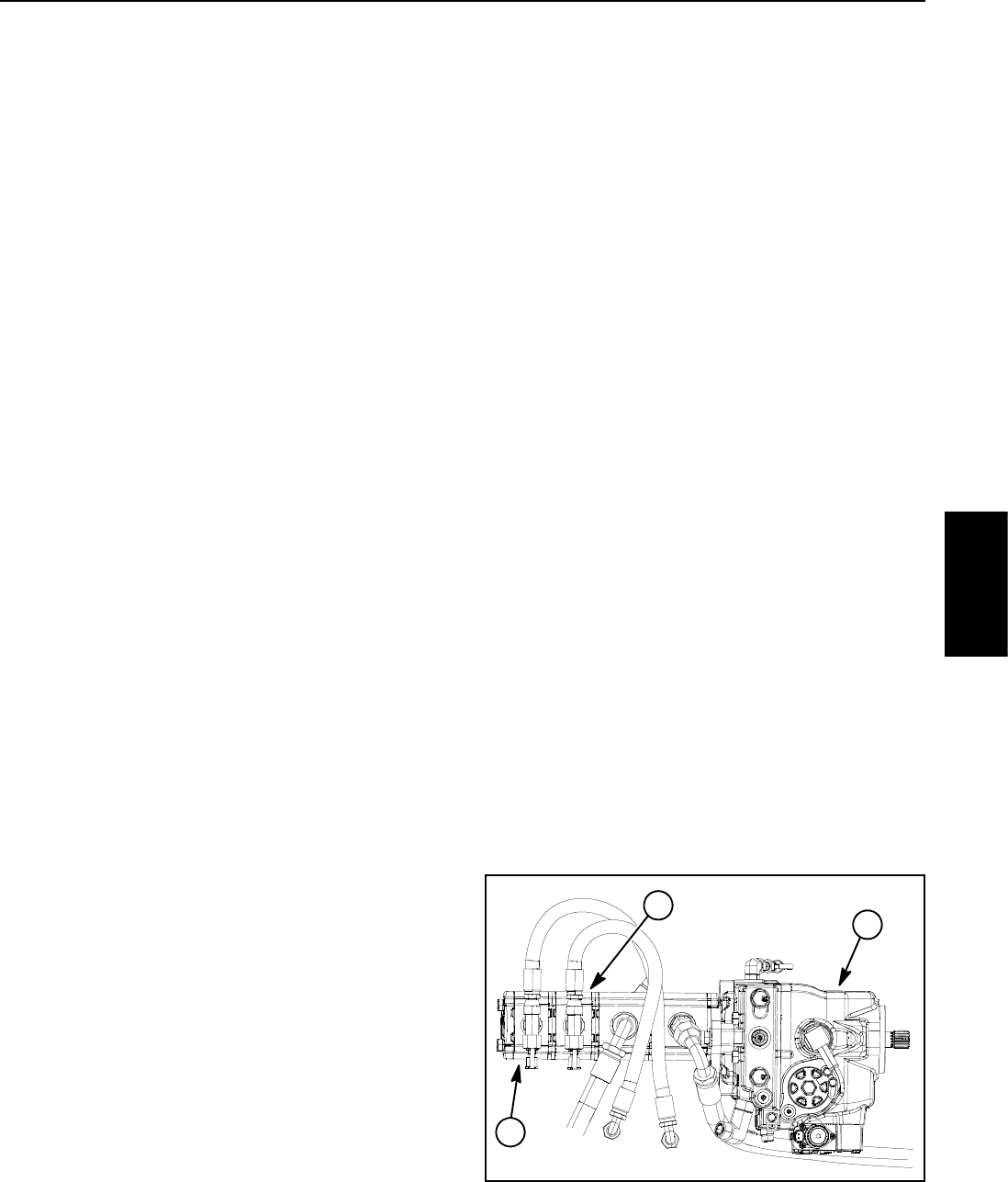

A four section gear pump is coupled to the piston (trac-

tion) pump (Fig. 14). The fourth gear pump section

(farthest from the piston pump) supplies hydraulic flow

to the steering circuit, the engine cooling fan circuit and

the traction charge circuit. The third gear pump section

supplies hydraulic flow to the engine cooling fan circuit,

the lift/lower circuit and the traction charge circuit.

So that there is sufficient oil flow for the engine co oling

fan circuit, oil flow from either or both of the third or fourth

gear pump section is used to drive the hydraulic cooling

fan motor depending on what other machine functions

are being used (steering, lift/lower). If additional oil flow

is needed for cooling fan operation in extreme condi-

tions (e.g. high ambient temperatures, cutting very

heavy grass), the TEC controller can allow flow from the

twopumpsectionstobecombined.

Oil flow from the third gear pump section is routed to the

combination manifold (port P3) where it is available

either for the lift/lower circuit or the engine cooling fan

circuit. When the lift/lower circuit is not being used (all lift

switches in the neutral position), solenoid valve (S1) in

the combination manifold is not energized and gear

pump section oil flow is directed toward the engine cool-

ing fan motor.

Priority oil flow from the fourth gear pump section is

provided to the steering circuit. All excess flow from this

gear pump section is no rmally routed to the traction

charge circuit by energized solenoid valve (S11). This

valve is energized by the T EC controller as long as the

lift/lower function is not being used and the hydraulic oil

and engine coolant temperatures are within normal

ranges. If inputs to the TEC controller suggest additional

oil flow is necessary for the cooling fan (e.g. lift/lower cir-

cuit is engaged or engine coolant temperature is elev-

ated), solenoid valve (S11) will be de--energized

allowing excess pump section oil flow to be directed to-

wardtheenginecoolingfanmotor.

Oil flow from the gear pump section(s) to the cooling fan

motor is controlled by the proportional relief valve (PRV)

in the combination manifold. This valve adjusts fan cir-

cuit pressure and flow based on a PWM (Pulse Width

Modulation) signal from the TEC controller. The control-

ler uses engine coolant and hydraulic oil temperatures

as inputs to determine the proper PWM signal for the

(PRV) valve. The fan circuit flow determines the speed

of the cooling fan motor a nd thus, the speed of the cool-

ing fan.

If the fan motor is stalled for any reason during machine

operation, the manifold proportional relief valve (PRV)

has a secondary function as a circuit relief to limit fan

motor pressure to 3250 PSI (224 bar).

When the engine is shut off, the over--running inertia

load of the engine cooling fan blades keeps driving the

fan motor and turns it into a pump. The check valve

(CV1) in the combination manifold will open to keep the

motor circuit full of oil so the fan motor will not cavitate.

Forward Direction Fan Operation

During normal, forward direction fan operation, circuit oil

flow is sent through the de--energized solenoid valve

(S10) in the combination manifold to rotate the cooling

fan motor. Return flow from the motor re--enters the

manifold (port M2), through the de--energized solenoid

valve (S10), to the oil filter and then out of the manifold

(port CH2). After exiting the manifold, circuit oil is routed

to the traction charge circuit.

Reverse Direction Fan Operation

The TEC controller can reverse the cooling fan to clean

debris from the rear intake screen. If hydraulic oil and/or

engine coolant temperatures increase to an unsuitable

level, a high PWM signal is sent to the (PRV) valve to

slow the cooling fan and direct all pump oil flow to the

traction charge circuit. The controller then energizes so-

lenoid valve (S10) in the combination manifold to re-

verse cooling fan motor oil flow so that the motor runs in

the r everse direction. A lower PWM signal is sent to the

(PRV) valve allowing oil flow to return to the fan motor

but in the reverse direction causing the motor and cool-

ing fan to run in reverse. The controller determines the

length of time that the fan should be run in reverse be-

fore fan rotation is returned to the forward direction.

NOTE: The operator can manually cause the cooling

fan to reverse by simultaneously pressing the right and

left buttons on the InfoCenter display.

1. Piston (traction) pump

2. 4

th

gear pump section

3. 3

rd

gear pump section

Figure 14

2

3

1

Hydraulic

System