Groundsmaster 4100--D/4110--DPage 3 -- 8Yanmar Diesel Engine

Yanmar Engine: Models 30606 and 30608

The engine used on Groundsmaster models 30606 and

30608 is a Yanmar TNV Series, turbocharged, diesel

engine that complies with EPA Tier 4 emission regula-

tions. Engine features include an electronic control unit

(ECU) that controls a common rail fuel injection system

with direct injection, water--cooled exhaust gas recircu-

lation (EGR), an electronic governor, an exhaust system

diesel oxidation catalyst (DOC) and an exhaust diesel

particulate filter (DPF) with active regeneration. Glow

plugs are used to assist starting the engine. Numerous

engine sensors are used to allow the engine ECU to

monitor and control engine operation for optimum en-

gine performance.

During machine operation, if an engine fault occurs, the

machine InfoCenter display can be used to identify the

fault. Also, the Yanmar SMARTASSIST--Direct electron-

ic control diagnostics service system is available to con-

firm the real--time engine running status and to offer

timely technical services.

The exhaust system DPF has four (4) modes for main-

tenance: passive regeneration, assist regeneration, re-

set regeneration and stationary regeneration.

Passive regeneration is the primary mode regenera-

tion that occurs during normal operation. When the en-

gine is running at normal loads, the exhaust

temperature will keep the DPF above the minimum tem-

perature for regeneration so normal particulate matter

(PM) accumulation in the DPF is expected.

Assist regeneration occurs if the engine ECU senses

that the DPF backpressure has increased to its maxim-

um threshold. During assist regeneration, the intake

throttle valve limits the air flow into the engine while the

injectors add additional fuel. This process increases the

DPF temperature which allows accumulated particulate

to burn off, without changing the load on the engine.

Burning of the accumulated PM decreases the pressure

across the DPF. The assist regeneration is completed

automatically when necessary. A small icon will be dis-

played on the I nfoCenter during assist regeneration

(Fig. 5) to inform the operator. The machine can contin-

ue to be used during an assist regeneration.

Reset regeneration takes place at a time interval

(every 100 hours) to reset the baseline sensor readings

in the DPF. The reset regeneration ensures that the en-

gine is running at peak efficiency. During this mode, post

injection is the means of increasing the DPF temperat-

ure. The reset regeneration is completed automatically

when necessary. A small icon willbe displayed on the In-

foCenter during reset regeneration (Fig. 5) to inform the

operator. The machine can continue to be used during

a reset regeneration.

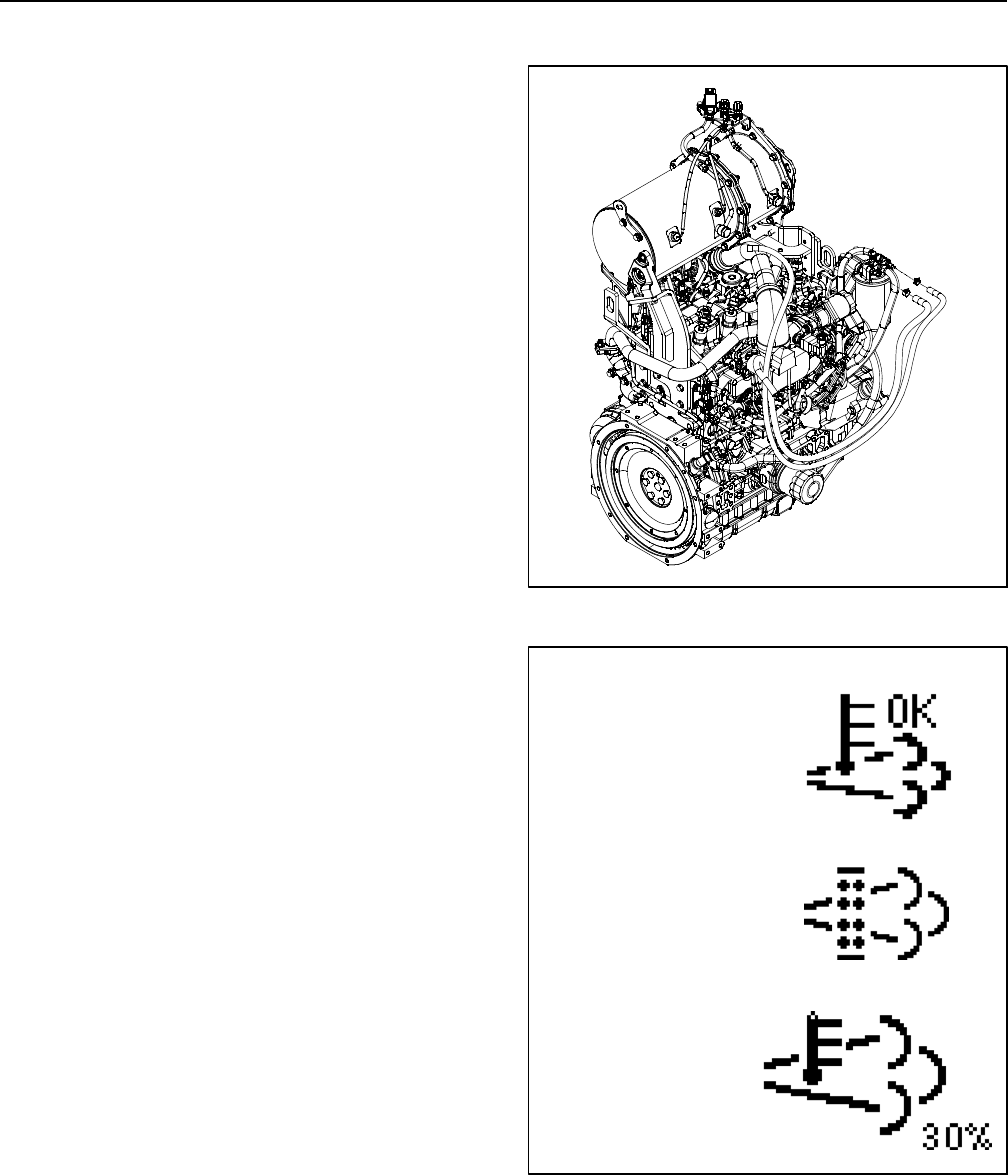

Figure 4

Figure 5

ICON

ASSIST OR RESET

REGENERATION

ICON

REGENERATION

STATIONARY

IN PROCESS

ICON

REGENERATION

STATIONARY

REQUEST

NOTE: If the engine is turned off during an assist or re-

set regeneration process, the regeneration will resume

once the engine is restarted and required temperature

level is reached.