Groundsmaster 4100--D/4110--D Hydraulic SystemPage 4 -- 109

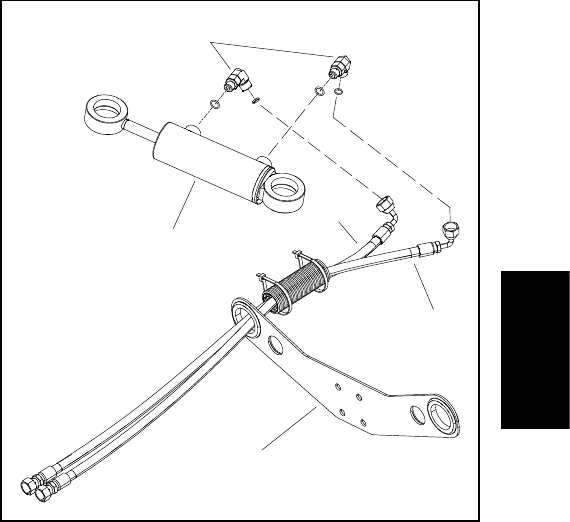

Removal (Fig. 81)

1. Park machine on a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

3. To prevent contamination of hydraulic system during

cylinder removal, thoroughly clean exterior of cylinder

and fittings.

NOTE: To ease installation, label the hydraulic hosesto

show their correct position on the steering cylinder.

4. Remove hydraulic hoses from steering cylinder (Fig.

82).

5. Remove cotter pins, slotted hex nuts, axle washer

and ball joint spacer from the threaded ends of ball

joints. Remove steering cylinder with ball joints from ma-

chine.

6. If hydraulic fittings are to be removed from steering

cylinder, mark fitting orientation to allow correct assem-

bly. Remove fittings from cylinder and discard O--rings.

7. If needed, remove ball joints from steering cylinder.

Installation (Fig. 81)

1. If removed, install ball joints into steering cylinder.

2. If fittings were removed from steering cylinder, lubri-

cate and place new O--rings onto fittings. Install fittings

into port openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of t his chapter).

3. Slide r am end ball joint through hole on steering arm.

Secure with axle washer and hex slotted nut. Slide fixed

end of cylinder through hole on axle. Secure with slotted

hex nut. Torque slotted hex nuts from 79 to 84 ft--lbs

(108 to 113 N--m) and then continue tightening the nut

until hex nut groove aligns with cotter pin hole in ball

joint. Install cotter pin to nut and ball joint.

4. Install hydraulic hoses to steering cylinder (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of this chapter).

5. Fill reservoir with new hydraulic fluid as required.

6. Properly fill hydraulic system (see Charge Hydraulic

System in this section).

7. After assembly is completed, operate steering cylin-

der to verify that hydraulic hoses andfittings are notcon-

tacted by anything.

1. Steering cylinder

2. Hydraulic hose

3. Hydraulic hose

4. 90

o

hydraulic fitting

5. Bulkhead mount plate

Figure 82

2

4

3

5

1

Hydraulic

System