Groundsmaster 4100--D/4110--DPage 5 -- 36Electrical System

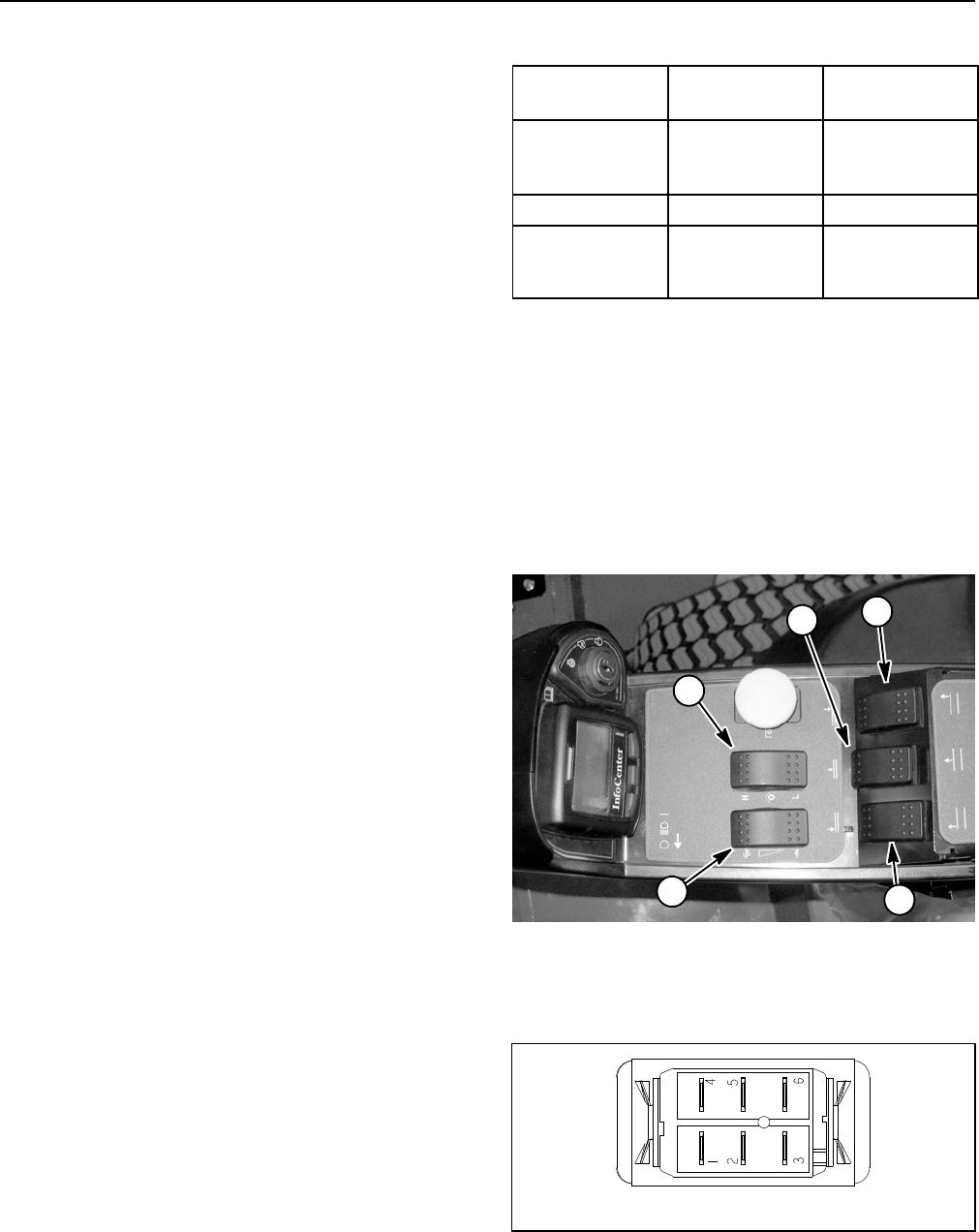

HI/LOW Speed, Engine Speed and Cutting Deck Lift Switches

The HI/LOW, engine speed and cutting deck lift

switches are all identical momentary switches. These

switches are located on the control arm (Fig. 39).

The HI/LOW speed switch is used as an input for the

TEC controller t o select either the HI (transport) or LOW

(mow) traction speed.

The engine speed switch is used as an input for the en-

gine electronic control unit to raise or lower the engine

speed. When the switchis depressed and held inthe for-

ward position, the engine speed will increase. Con-

versely, when the rear of the switchis depressed, engine

speed will decrease.

The cutting deck lift switches are used as inputs for the

TEC controller to raise or lower the cutting deck sec-

tions. When the front of a lift switch is depressed, the

controlled deck section will lower. When the rear of a lift

switch is depressed and held, the controlled deck sec-

tions will raise.

NOTE: To raise or lower the deck sections, the operator

seat has to be occupied. Also, to lower the cutting deck

sections, the traction speed has to be in LOW (mow)

range.

Testing

1. Before disconnecting a switch for testing, the switch

and its circuit wiring should be testedas a TEC input with

the InfoCenter Display (see InfoCenter Display in this

chapter). If the InfoCenter verifies that the switch and

circuit wiring are functioning correctly, no further switch

testing is necessary. If, however, the InfoCenter deter-

mines that the switch and circuit wiring are not function-

ing correctly, proceed with test.

2. Make sure ignition switch is OFF. Remove key from

ignition switch.

3. Disassemble control arm to gain access to switch

that is to be tested (see Control Arm in the Service and

Repairs section of Chapter 7 -- Chassis).

4. Disconnect harness electrical connector from the

switch that is to be tested.

5. The switch terminals are marked as shown in Figure

40. The circuit logic of the switch is shown in the chart

below. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the various terminals for each

position. Verify continuity between switch terminals. Re-

place switch if testing identifies a faulty switch.

SWITCH

POSITION

CLOSED

CIRCUITS

OPEN

CIRCUITS

FRONT OF

SWITCH

PRESSED

2+3

5+6

2+1

5+4

NEUTRAL NONE ALL

REAR OF

SWITCH

PRESSED

2+1

5+4

2+3

5+6

6. If switch tests correctly and circuit problem still ex-

ists, check wire harness (see Electrical Schematics and

Wire Harness Drawings in Chapter 10 -- Foldout Draw-

ings).

7. After testing is completed, connect wire harness

connector to the switch.

8. Assemble control arm (see Control Arm in the Ser-

vice and Repairs section of Chapter 7 -- Chassis).

1. HI/LOW speed switch

2. Engine speed switch

3. RH deck lift switch

4. Center deck lift switch

5. LH deck lift switch

Figure 39

2

1

3

5

4

Figure 40

BACK OF SWITCH