Groundsmaster 4100--D/4110--D Page 7 -- 5 Chassis

Removal (Fig. 3)

1. Park machine on a level surface, lower cutting deck,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Remove front cutting deck (see Cutting Deck Re-

moval in Chapter 8 -- Cutting Deck).

CAUTION

When changing attachments, tires or perform -

ing other service, use correct jacks and sup-

ports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

the machine. Always chock or blockwheels. Use

jack stands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

3. Chock rear wheels and jack u p front of machine.

Support machine on jack stands. Remove front wheel

next to lift arm that is being removed.

4. Remove flange head screw and lock nut that secure

lift cylinder pin to lift arm. Remove pin and separate lift

cylinder from lift arm.

5. Remove lock nut that secures lift arm pin. Support lift

arm and slide pin from frame and lift arm. Remove lift

armfromframe.

6. As needed, disassemble lift arm:

A. Remove height--of--cut chain (items 21 and 22 in

Fig. 3).

B. Remove damper assembly (items 6, 7 and 8 in

Fig. 3).

C. Remove flange nut, flat washer and support hub

(item 39 in Fig. 3) from tapered stud in end of lift arm.

D. Remove tapered stud with spherical bearingfrom

lift arm after removing retaining ring from lift arm (Fig.

5). Remove flange nut and spherical bearing from

stud.

E. Press flange bushings from lift arm (Fig. 5).

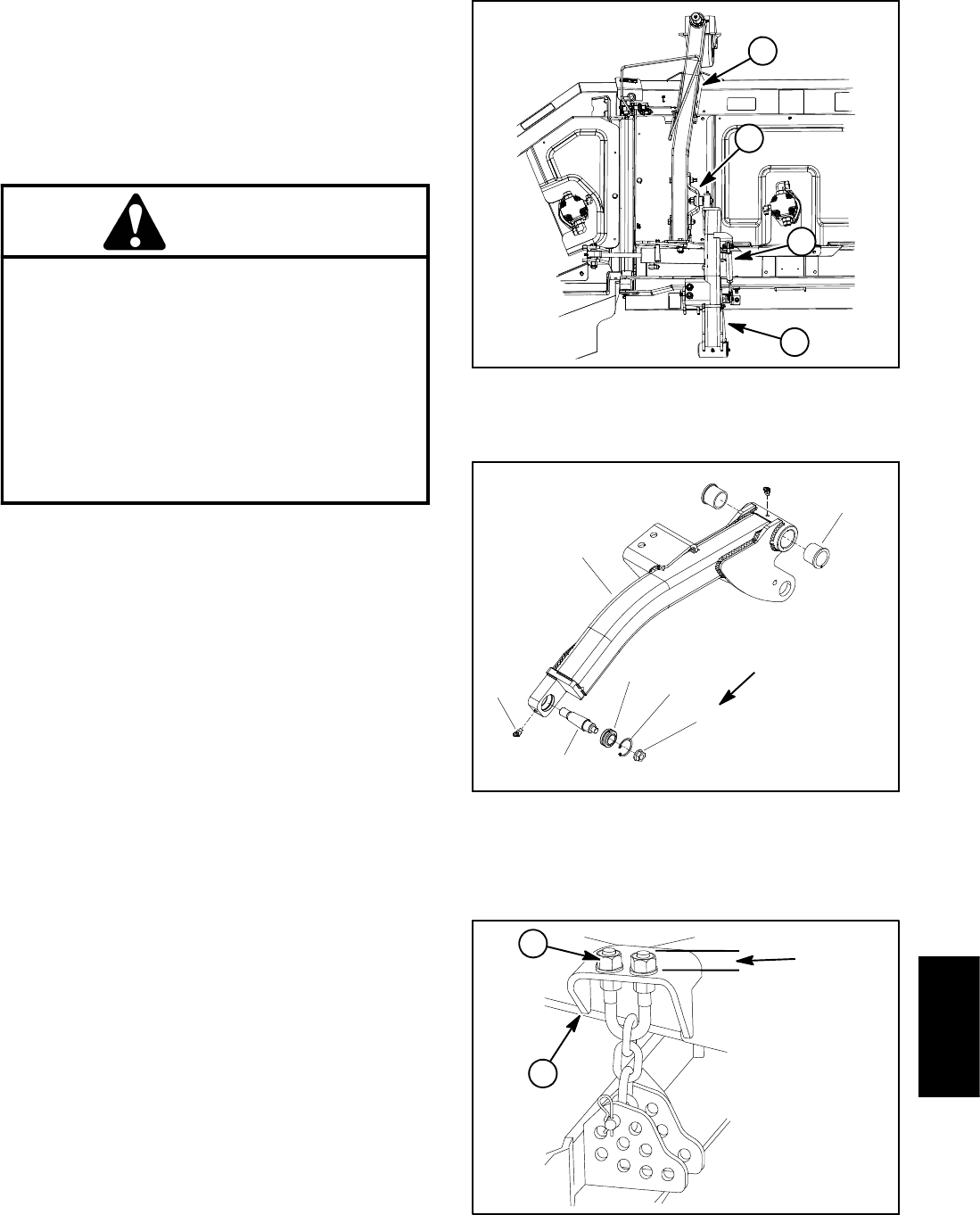

Figure 4

1. Lift arm

2. Deck castor arm

3. Support hub

4. Damper

1

2

3

4

1. Lift arm (RH shown)

2. Flange nut

3. Retaining ring

4. Spherical bearing

5. Tapered stud

6. Flange bushing (2 used)

7. Grease fitting (2 used)

Figure 5

2

1

4

3

5

6

7

100 to 140 in--lb

(12to15N--m)

1. Lift arm 2 . U--bolt threads

Figure 6

0.750 in.

(19.1 mm)

1

2

Chassis