Groundsmaster 4100--D/4110--DPage 5 -- 46Electrical System

Relays with Four (4) Terminals

Your Groundsmaster uses a number of electrical relays

that have four (4) terminals. A tag near the wire harness

relay connector can be used to identify each relay.

The main power relay is used to provide current to most

of the fuse protected circuits (operator seat, InfoCenter

display, power point and optional electric equipment).

The main power relay is energized when the ignition

switch is in the RUN or START position.

The TEC power relay is used to provide current to the

fuse protected circuits for the TEC controller. The TEC

power relay is energized when the ignition switch is in

the RUN or START position.

The cab power r elay is used on Groundsmaster 4110--D

machines to provide current to the operator cab electri-

cal components. The cab power relay is energized when

theignitionswitchisintheRUNorSTARTposition.

The start relay is used to provide current to the engine

starter motor solenoid. The start relay is energized by

the engine ECU.

The air heater relay is used on models 30602 and 30604

to provide current for the engine air heater used forstart-

ing a cold engine. When necessary, the air heater relay

is energized by the engine ECU.

The glow relay is used on models 30606 and 30608 to

provide current to the engine glow p lugs when ener-

gized by the engine ECU.

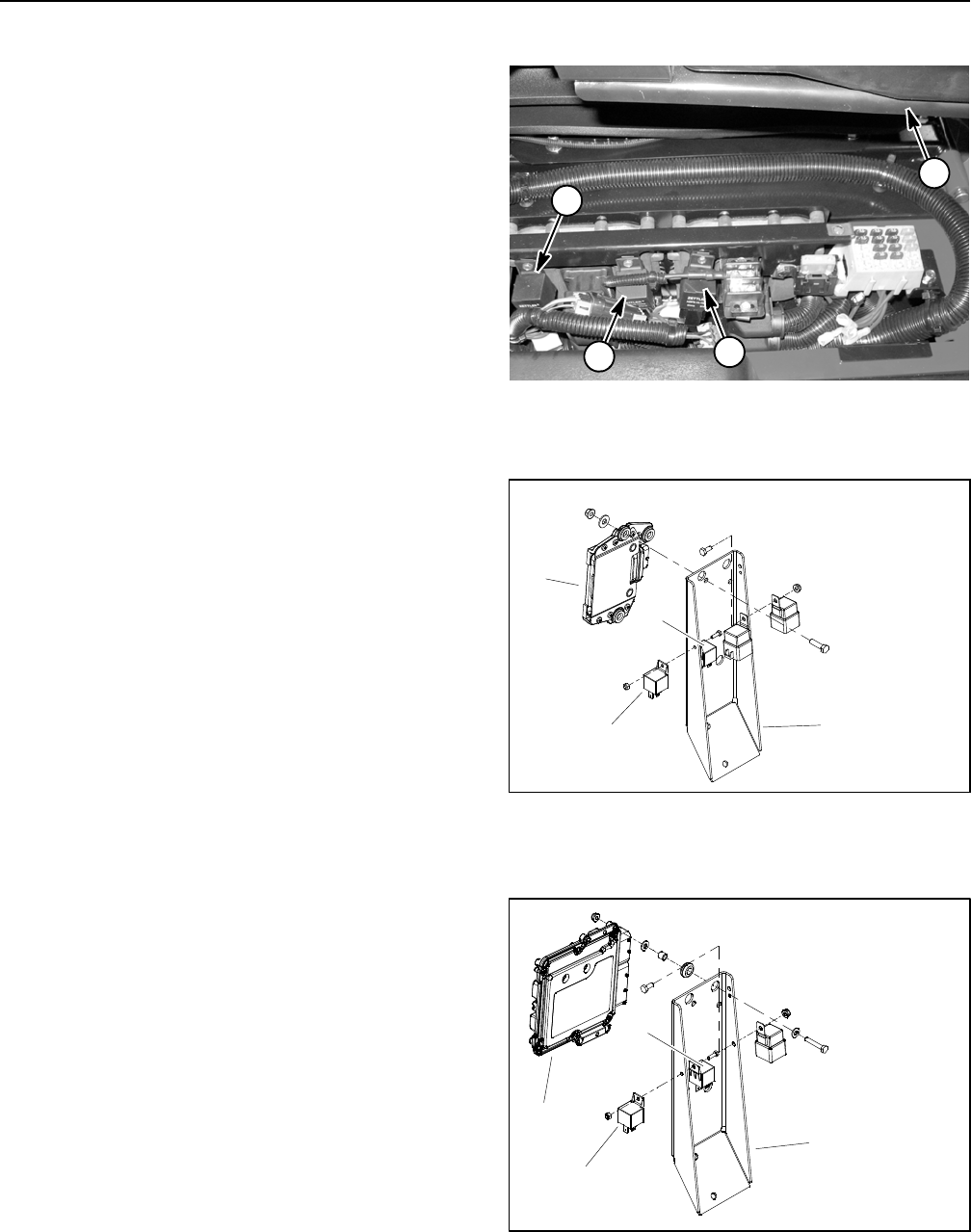

The main power, TEC power and cab power relays are

located under the controller cover next to the operator

seat (Fig. 56). The start, air heater and glow relays are

attached to the controller mount on the right side of the

engine (Fig. 57 or 58).

Testing

1. Parkmachineonalevelsurface, lower cutting deck,

stop engine, engage parking brake and remove key

from the ignition switch.

2. To make sure that machine operation does not occur

unexpectedly, disconnect negative (--) cable from bat-

tery and then disconnect positive (+) cable from battery

(see Battery Service in the Service and Repairs section

of this chapter).

3. Locate relay that is to be tested.

4. Disconnect wire harness connector from relay. Re-

move relay from mounting bracket for testing.

1. Main power relay

2. TEC power relay

3. Cab power relay

4. Operator seat

Figure 56

1

2

4

3

1. Controller mount

2. Engine ECU

3. Start relay

4. Airheaterrelay

Figure 57

MODELS 30602 AND 30604

1

3

2

4

1. Controller mount

2. Engine ECU

3. Start relay

4. Glow relay

Figure 58

MODELS 30606 AND 30608

2

3

1

4