Groundsmaster 4100--D/4110--DHydraulic System Page 4 -- 116

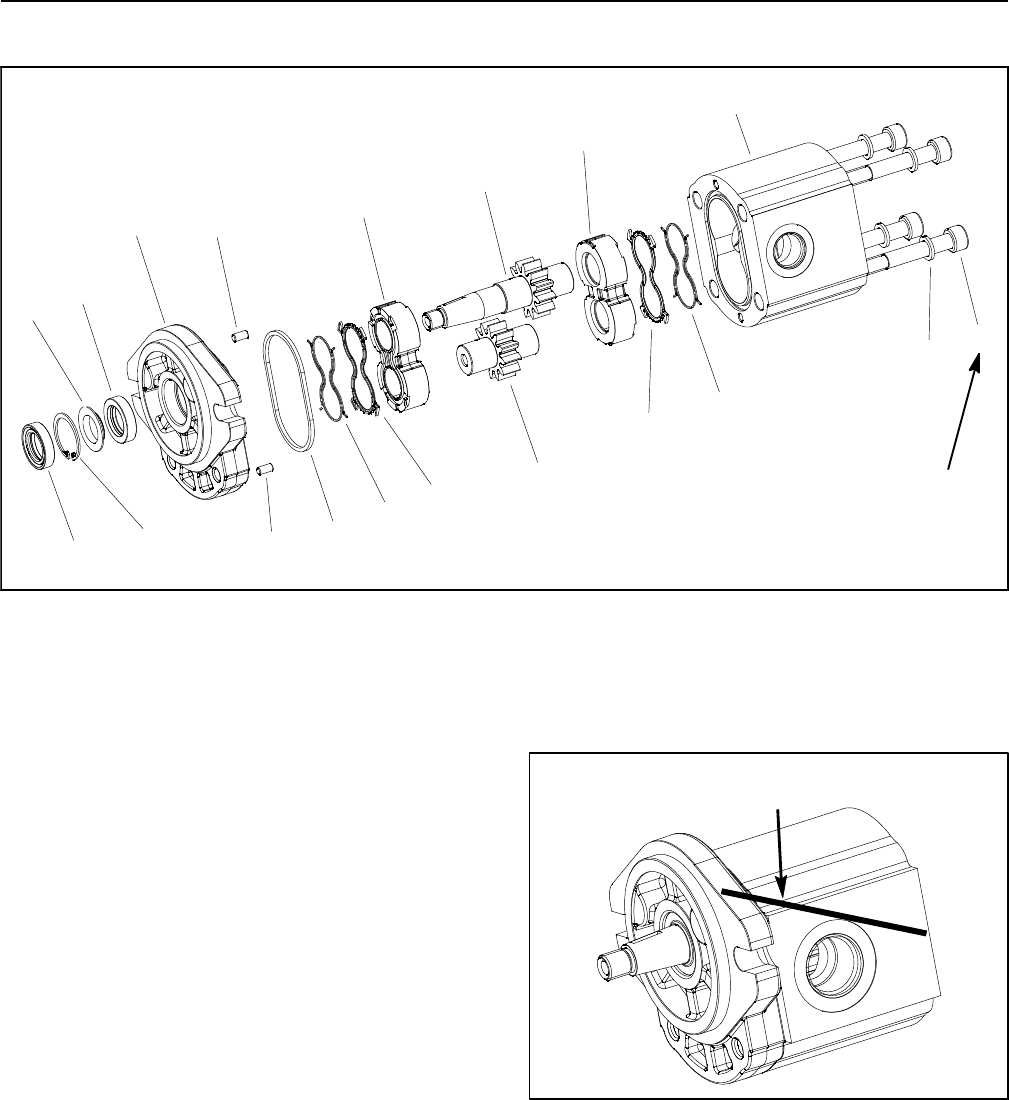

Engine Cooling Fan Motor Service

1. Flange washer

2. O--ring

3. Front flange

4. Dust seal

5. Retaining ring

6. Front wear plate

7. Shaft seal

8. Backup gasket

9. Pressure seal

10. Rear wear plate

11. Body

12. Idler gear

13. Cap screw (4 used)

14. Dowel (2 used)

15. Drive gear

16. W asher (4 used)

Figure 86

8

7

4

3

2

5

6

9

10

11

9

12

13

8

14

16

15

14

1

(45 N--m)

33 ft--lb

NOTE: Internal components for a cooling fan motor are

not available separately. Disassemble motor for clean-

ing, inspection and seal replacement only.

Disassembly (Fig. 86)

1. Plug motor ports and clean the outside of the motor

thoroughly. After cleaning, remove plugs and drain any

oil out of the motor.

2. Useamarkertomakeadiagonal line across the

front flange and body for assembly purposes (Fig. 87).

IMPORTANT: Prevent damage when clamping the

fan motor into a vise; clamp on the front flange only.

Also, use a vise with soft jaws.

3. Clamp front flange of motor in a vise with soft jaws

with the shaft end down.

4. Loosen cap screws from the rear cover.

5. Remove motor from the vise. Turn motor so that the

shaft end is facing down. Remove cap screws.

6. Carefully remove body. Lift body straight up to re-

move. Make sure the rear wear plate remains on the

drive and idler gear shafts. Remove and discard O--

rings from the body. Locate and retrieve dowel pins.

Figure 87

MARKER LINE

IMPORTANT: Note position of the open and closed

side of the wear plates before removing. Also, iden-

tify wear plates (front and rear) with a marker for

proper assembly.

7. Carefully remove rear wear plate, idler gear, drive

gear and front wear plate from the front flange.

8. Remove and discard back--up gaskets and pressure

seals from wear plates.