Groundsmaster 4100--D/4110--D Page 6 -- 19 Axles, Planetaries and Brakes

Removal (Fig. 12)

1. Park machine on a level surface, lower cutting deck,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Drain oil from rear axle and axle gearbox (Figs. 13

and 14).

3. Chock front wheels and jack up rear of machine (see

Jacking Instructions in Chapter 1 -- Safety). Support ma-

chine with appropriate jack stands.

4. Remove both wheels from rear axle.

5. Remove hydraulic motor from rear axle assembly

(see Rear Axle Motor in the Service and Repairs section

of Chapter 4 -- Hydraulic System).

6. Remove st eering cylinder from rear axle (see Steer-

ing Cylinder in the Service and Repairs section of Chap-

ter 4 -- Hydraulic System).

7. Remove cap screws and lock washers that secure

bulkhead mount plate (item 15) to rear axle. Separate

mount plate from rear axle and support it along with at-

tached hydraulic hoses and tubes to allow the rear axle

to be lowered from machine.

8. If required, remove tie rod ends from steering arms

on rear axle (Fig. 15). Remove the cotter pins and castle

nuts from the tie rod ball joints. Use a ball joint fork and

remove the tie rod ends from the axle steering arms.

9. Support rear axle to prevent it from falling. Remove

six (6) cap screws, flat washers and lock nuts that se-

cure rear axle mount to machine frame. Lower rear axle

and rear axle mount from machine.

10.Remove lock nut and washer from rear axle pin that

attaches rear axle to rear axle mount. Remove washer

head screw that secures flange of rear axle pin to axle

mount (Fig. 16).

11.Remove rear axle pin from rear axle andmount. Sep-

arate rear axle mount from rear axle. Note location of

thrust washers (items 28 and 29) on both ends of axle

mounting boss.

Installation (Fig. 12)

1. Position rear axle mount to axle. Install thrust wash-

ers (items 28 and 29) between axle boss and axle

mount. The thicker thrust washer should be installed on

thehydraulicmotorendoftheaxle(towardtherearof

the machine). With washers installed, there should be

from 0.002” to 0.020” (0.05 mm to 0.51 mm) clearance

between rear axle mount and axle mounting boss. Add

thrust washers if needed to adjust clearance.

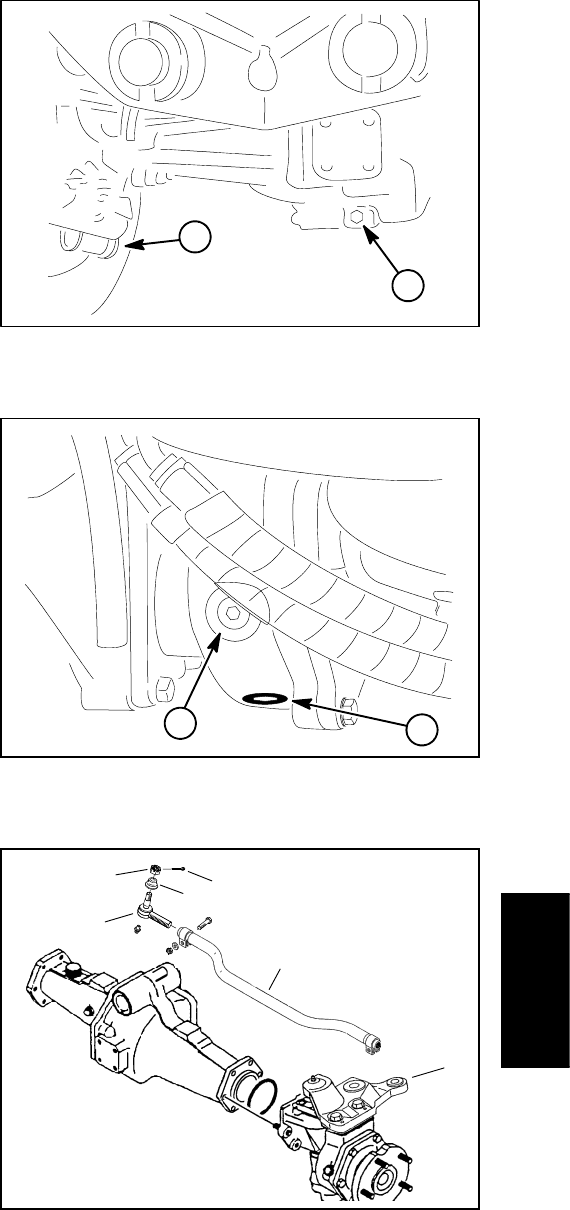

1. Center axle drain plug 2. Outside plug (2 used)

Figure 13

1

2

1. Gearbox drain plug 2. Gearbox fill plug

Figure 14

1

2

1. Tie rod

2. Dust cover

3. Cotter pin

4. Castle nut

5. Tie rod end

6. Steering arm (LH)

Figure 15

1

2

3

5

4

6

Axles, Planetaries

and Brakes