Groundsmaster 4100--D/4110--DPage 6 -- 32Axles, Planetaries and Brakes

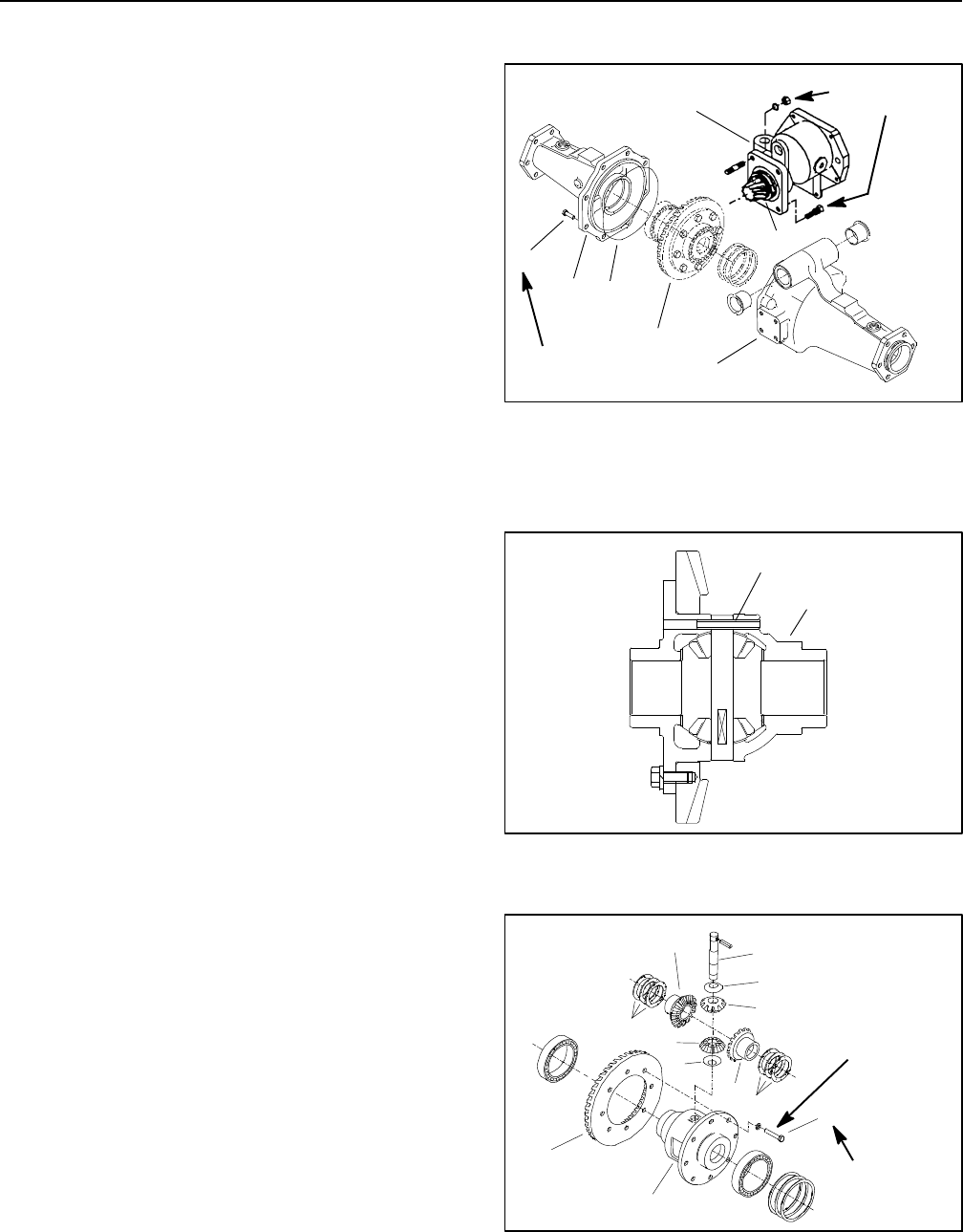

Differential Gear

The following procedures assume the rear axle assem-

bly has been removed from the machine.

Removal

1. Remove bevel gear case/axle case assemblies (see

Bevel Gear Case/Axle Case Assembly in this section of

this manual).

IMPORTANT: Do not interchange right and left dif-

ferential shafts assemblies.

2. Mark and pull the differential shaft assemblies from

theaxlesupport.

3. Remove input shaft/pinion gear assembly, shims

and O-ring from the axle support (Fig. 39).

4. Remove the axle support case screws. Separate the

axle support halves and remove the O-ring.

5. Remove the differential gear assembly, bearings and

adjusting shims from the axle case.

6. Drive the spring pin from the differential case with a

punch and hammer. Discard the spring pin (Fig. 40).

NOTE: Mark and arrange all components so they can

be reassembled in their original position.

7. Remove the differential pinion shaft, pinion gears

and pinion washers. Remove the differential side gears

and side gear shims. Remove t he ring gear only if it will

be replaced ( Fig. 41).

NOTE: Replacement ring gears are only available in

matched ring and pinion sets.

1. Gear Case

2. Pinion Gear

3. Axle support (left)

4. Axle support (right)

5. Case screw (8 used)

6. Differential gear

7. O-ring

Figure 39

1

3

4

5

6

7

2

35 to 41 ft--lb

(47 to 56 N--m)

35 to 41 ft--lb

(47to56N--m)

1. Differential case 2. Spring pin

Figure 40

1

2

1. Differential pinion shaft

2. Pinion gear

3. Pinion washer

4. Side gear

5. Side gear shims

6. Ring gear

7. Differential case

8. Bolt/washer (8 used)

Figure 41

22 to 25 ft--lb

(30to34N--m)

Threadlocking

Compound

1

3

4

5

6

7

2

2

3

4

5

8