Groundsmaster 4100--D/4110--DPage 5 -- 50Electrical System

Toro Electronic Controllers (TEC)

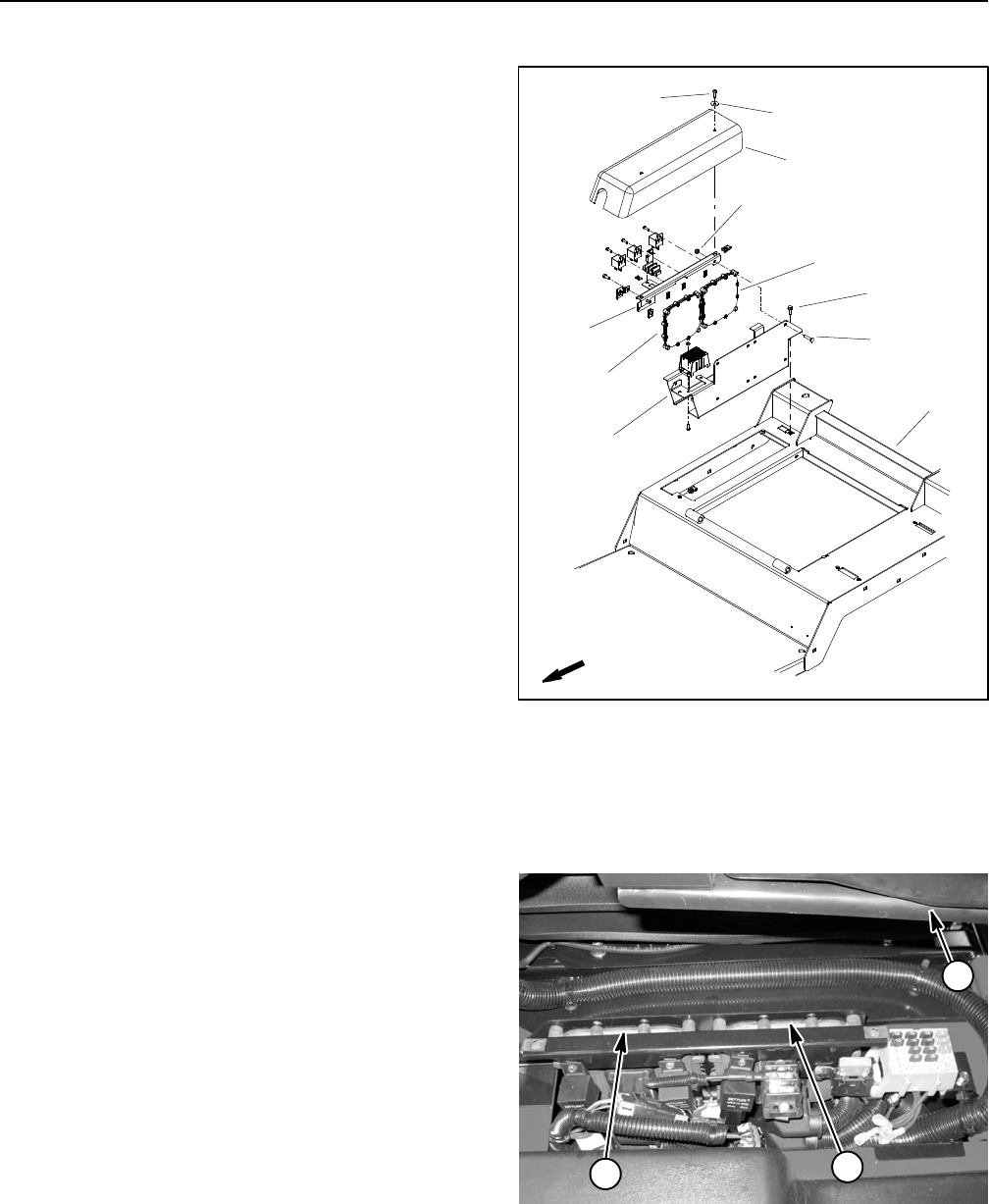

Groundsmaster 4100--D and 4110--D machines use two

(2) ToroElectronic Controllers (TEC) to control electrical

system operation. The controllers are a ttached to the

operator platform under the controller cover (Figs. 63

and 64).

Logic power is provided to the controllers as long as the

battery cables are connected to the battery. A pair of 2

Amp fuses (fuse D--1 for the front controller and fuse

D--2 for the rear controller) provide circuit protection for

this logic power to the controllers.

The front TEC controller monitors the states of the fol-

lowing components as inputs: ignition switch, traction

pedal position sensor, parking brake switch, HI/LOW

speed switch, service brake switches, seat switch, en-

gine speed switch, hydraulic temperature sender, turn

signal switch (if equipped) and hazard switch (if

equipped).

The front TEC controller controls electrical output to the

engine ECU (start and run functions), fan drive solenoid

coils (direction and flow source), traction (piston) pump

solenoids (forward and reverse) and traction solenoid

coil (HI/LOW speed). Additionally, electrical o utputs for

brake lights, turn lights and warning lights on Grounds-

master 4110--D machines are provided by the front TEC

controller. Circuit protection for front TEC outputs is pro-

vided by three (3) 7.5 Amp fuses (fuse locations A--1,

B--1 and C--1).

The rear TEC controller monitors the states of the fol-

lowing components a s inputs: ignition switch, cutting

deck lift switches, PTO switch, cruise control switch and

wing deck position switches.

The rear TEC controller controls electrical output to the

PTO solenoid coils, lift/lower solenoid coils and fan drive

solenoid coil (speed). Circuit protection for rear TEC

outputs is provided by three (3) 7.5 Amp fuses (fuse loc-

ations A--2, B--2 and C--2).

The InfoCenter display should be used to check inputs

and outputs of the TEC controllers. Information on using

the InfoCenter is included in the InfoCenter Display sec-

tion of this chapter.

The diagram in Figure 65 depicts the connection termi-

nal functions for the TEC controllers. Note that electrical

power for controller outputs is p rovided through three (3)

connectors (PWR 2, PWR 3 and PWR 4) eachprotected

with a 7.5 amp fuse. A fifty (50) pin wire harness connec-

tor attaches to the controller. The connector pins are

identified in the diagram in Figure 65. The layout of the

wire harness connectors that plug into the TEC control-

lersisshowninFig.66.

1. Controller cover

2. Screw (2 used)

3. Flat washer (2 used)

4. Flange screw (2 used)

5. Power mount

6. Relay mount

7. Carriage screw (8 used)

8. Flange nut (8 used)

9. Front TEC controller

10. Rear TEC controller

11. Operator platform

Figure 63

FRONT

2

3

7

1

6

4

5

8

9

10

11

1. Front TEC controller

2. Rear TEC controller

3. Operator seat

Figure 64

2

1

3