Groundsmaster 4100--D/4110--D Hydraulic SystemPage 4 -- 65

The cooling fan circuit test should be performed to make

sure that the engine cooling fan circuit has the correct

system pressure and fan speed.

Procedure for Engine Cooling Fan Circuit

Test

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

1. Park machine on a level surface with the cutting deck

lowered and off. Make sure hydraulic oil is at normal op-

erating temperature, engine is off and the parking brake

is applied.

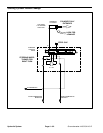

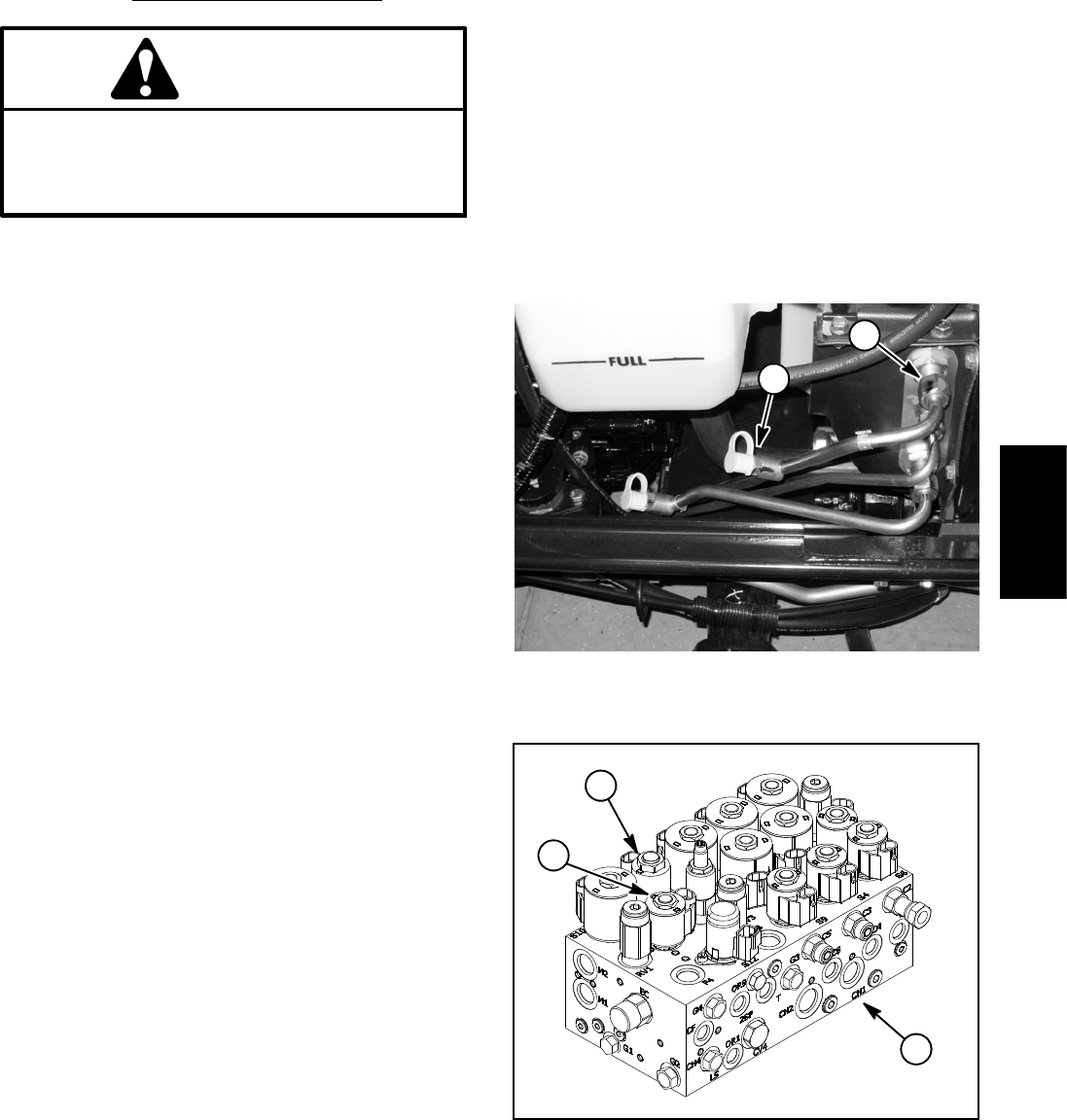

2. Raiseandsupporthoodtogainaccesstothehy-

draulic tubes that supply hydraulic flow to engine cooling

fan motor (Fig. 45). Connect a 5,000 PSI (345 bar) pres-

sure gauge with hydraulic hose attached to test port on

hydraulic tube connected inthe upper location on radiat-

or shroud.

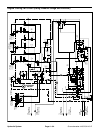

3. Raise seat t o gain access to the combination man-

ifold (Fig. 46). Locate PRV and S11 solenoid valves on

manifold.

4. Have a phototac available to identify cooling fan

speed once engine is running.

5. Start engine and increase engine speed to high idle

speed. DO NOT engage the cutting deck.

6. While monitoring the pressure gauge and using the

phototac to identify the cooling fan speed, disconnect

the wire harness connectors from the PRV solenoid

(white/green and black wires) and S11 solenoid (violet

and black wires) on combination manifold (Fig. 46). Both

fan speed and pressure should increase and stabilize

after the solenoids are disconnected.

PRESSURE GAUGE READING TO BE approxi-

mately 3250 PSI (224 bar).

PHOTOTAC READING (FAN SPEED) TO BE ap-

proximately 2800 to 3000 RPM.

NOTE: The cooling fan speed will depend on hydraulic

oil temperature. Higher oil temperatures will result in

slower fan speed.

7. Stop engine and record test results.

8. If circuit pressure rises to approximately 3250 PSI

(224 bar) but fan speed is low, consider that the fan mo-

tor is worn or damaged. If pressure and fan speed are

both low, consider that the gear pump section is worn or

damaged (see Gear Pump Flow Test in this section).

NOTE: If pressure and fan speed are both low and gear

pump flow proves to be correct, suspect that engine

cooling fan circuit cartridge valve seals in combination

manifold(e.g.S10,S11,PRV)areleakingorfaulty(see

Combination Manifold Service in the Service and Re-

pairs section of this chapter).

9. When testing is complete, remove pressure gauge

from hydraulic tube test port and reconnect wire harness

connectors to PRV and S11 solenoids. Lower and se-

cure hood and operator seat.

1. Upper hydraulic tube 2. Test port

Figure 45

1

2

1. Combination manifold

2. PRV solenoid

3. S11 solenoid

Figure 46

1

2

3

Hydraulic

System