Groundsmaster 4100--D/4110--DPage 7 -- 14Chassis

Assembly (Fig. 12)

1. Make sure that all machine components are installed

below operator platform before platform is lowered to

frame.

IMPORTANT: Make sure to not damage the electric-

al wire harness or other components while lowering

the operator platform.

2. Carefully lower operator platform and position over

center mounts (item 4) that are installed in the frame.

3. Secure operator platform to machine frame with four

(4) cap screws, flat washers, plain washers and lock

nuts. Torque lock nuts from 95 to 115 ft--lb (129 to 155

N--m).

4. Connect all electrical wire harness connections

between operator platform components and main frame

locations.

5. On Groundsmaster 4110--D machines:

A. Install operator cab to machine.

B. Secure operator cab coolant and air conditioner

hoses in engine compartment with cable ties in loca-

tions noted during disassembly.

6. Connect both brake cables to brake pedals and op-

erator frame. Adjust brakes so that both pedals have 1/2

to 1 inch (13 to 25 mm) of free travel.

7. Position traction pedal assembly to operator plat-

form and secure with removed fasteners (Fig. 14). Con-

nect machine wire harness connector to position sensor

on traction pedal assembly.

8. Secure steering tower covers to machine (see Steer-

ing Tower in this section).

9. Connect positive battery cable from battery terminal

and then connect negative cable to battery (see Battery

Service in the Service and Repairs section of Chapter 5

-- Electrical System).

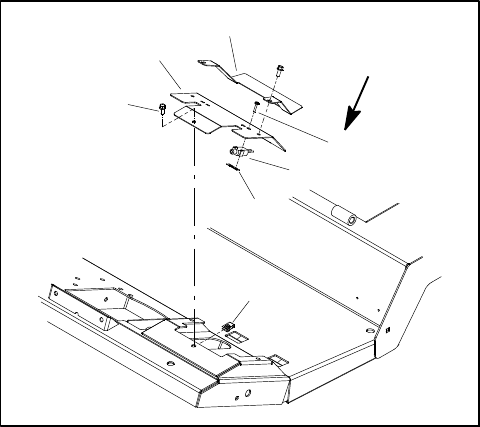

1. Flange screw (3 used)

2. Adjustment cover

3. Switch bracket

4. Brake switch (2 used)

5. Screw (2 per switch)

6. Switch nut (2 used)

7. Clip (3 used)

Figure 16

13 to 17 in--lb

(1.5 to 1.9 N--m)

1

3

5

2

4

6

7