Groundsmaster 4100--D/4110--D Page 7 -- 21 Chassis

NOTE: Most of the seat suspension components can

be serviced with the seat suspension base mounted to

the frame platform. If the air spring assembly (item 6) re-

quires removal, the seat suspension base will haveto be

removed from the seat platform.

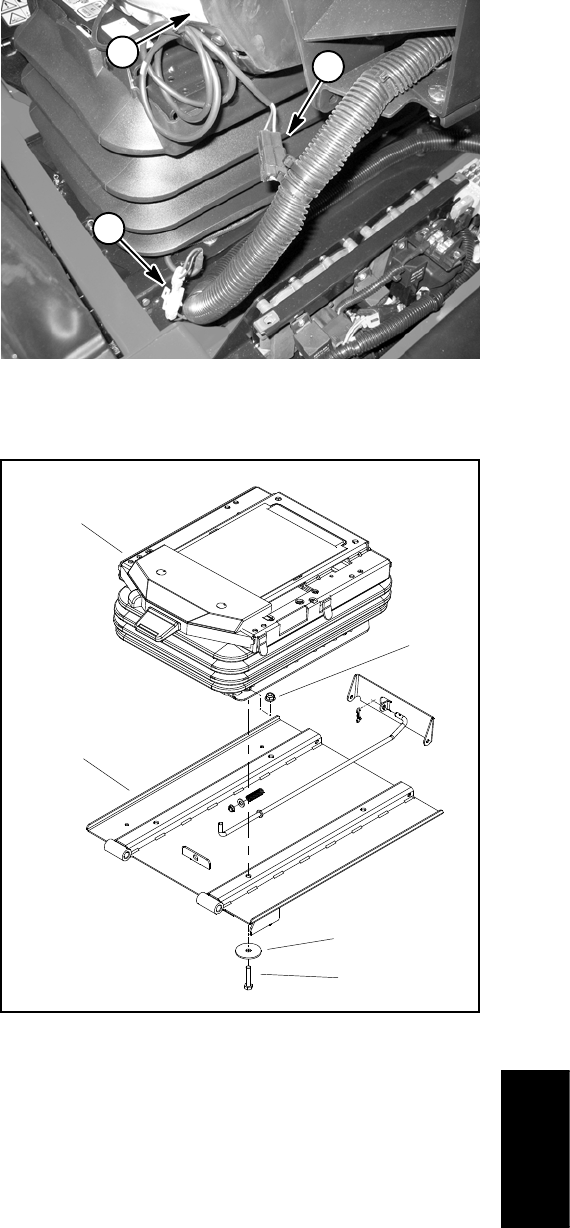

Disassembly (Fig. 22)

1. Remove operator seat from seat suspension (see

Operator Seat Removal in this section).

2. Disconnect seat suspension connector from ma-

chinewireharness(Fig.23).

3. If the air spring assembly (item 6) or base plate (item

37) requires removal, remove seat suspension from

seat plate (Fig. 24):

A. Raise and support seat plate assembly. Support

seat suspension to prevent it from falling.

B. Remove four (4) cap screws, flat washers and

flange nuts that secure seat suspension to seat

plate.

C. Remove seat suspension from machine.

4. Remove seat suspension components as needed

using Figure 22 as a guide.

Assembly (Fig. 22)

1. Install all removed seat suspension components us-

ingFigure22asaguide.

2. If seat suspension was removed from seat plate, se-

cure suspension to seat plate (Fig. 24):

A. Position seat suspension onto seat plate.

B. Secure seat suspension to seat plate with four (4)

cap screws, flat washers and flange nuts.

C. Lower and secure seat plate assembly.

3. Install operator seat to seat suspension (see Opera-

tor Seat Installation in this section).

4. Make sure that seat electrical connectors are con-

nected to machine wire harness (Fig. 23).

1. Operator seat

2. Seat switch connector

3. Suspension connector

Figure 23

1

2

3

1. Seat suspension

2. Flat washer (4 used)

3. Cap screw (4 used)

4. Flange nut (4 used)

5. Seat plate

Figure 24

4

1

2

3

5

Chassis