Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 45

Procedure for Traction Circuit Relief Pressure

Test

NOTE: Thetractionchargecircuitisdesignedtore-

place loss of hydraulic fluid from the closed loop traction

circuit.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

1. Park machine on a level surface with the cutting

decks lowered and off. Make sure hydraulic oil is at nor-

mal operating temperature, engine isoff and theparking

brake is applied.

When performing the traction circuit relief pres-

sure test, move machine to an open area, away

from people and obstructions.

CAUTION

2. Drive machine to an open area, lower cutting decks,

turn the engine off and apply the parking brake.

3. Connect a 10,000 PSI (700 bar) pressure gauge to

traction circuit test port for function to be checked (Fig.

28 or 29).

4. Start engine and increase engine speed to high idle

speed. Release parking brake. Make sure that HI/LOW

speed switch is in the HI (transport) position.

NOTE: If possible, turn off Smart Power

TM

by using the

InfoCenter display protected menu. Machines with TEC

software above revision level G will allow Smart

Power

TM

to be disabled fortesting. Check softwarerevi-

sion level using the InfoCenter About screen.

5. Sit on seat, apply brakesfully andslowly depress the

traction pedal in theappropriate direction(forward or re-

verse). While pushing traction pedal, look at pressure

reading on gauge:

GAUGE READING TO BE:

Forward: 4100 to 4600 PSI (283 to 317 bar)

Reverse: 4750 to 5250 PSI (328 to 362 bar)

6. Release traction pedal and stop engine. Record test

results.

7. If trac tion pressure is too low, inspect traction pump

relief valves (Fig. 28 or 29). Clean or replace relief

valves as necessary. These cartridge type valves are

factory set, and are not adjustable. If relief valves are in

good condition, traction pump or wheel motors should

be suspected of wear and inefficiency.

8. When testing is completed, disconnect pressure

gauge from test port. Secure dust cap to test fitting.

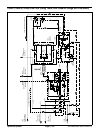

1. Forward traction port 2. Forward relief valve

Figure 28

FRONT

1

2

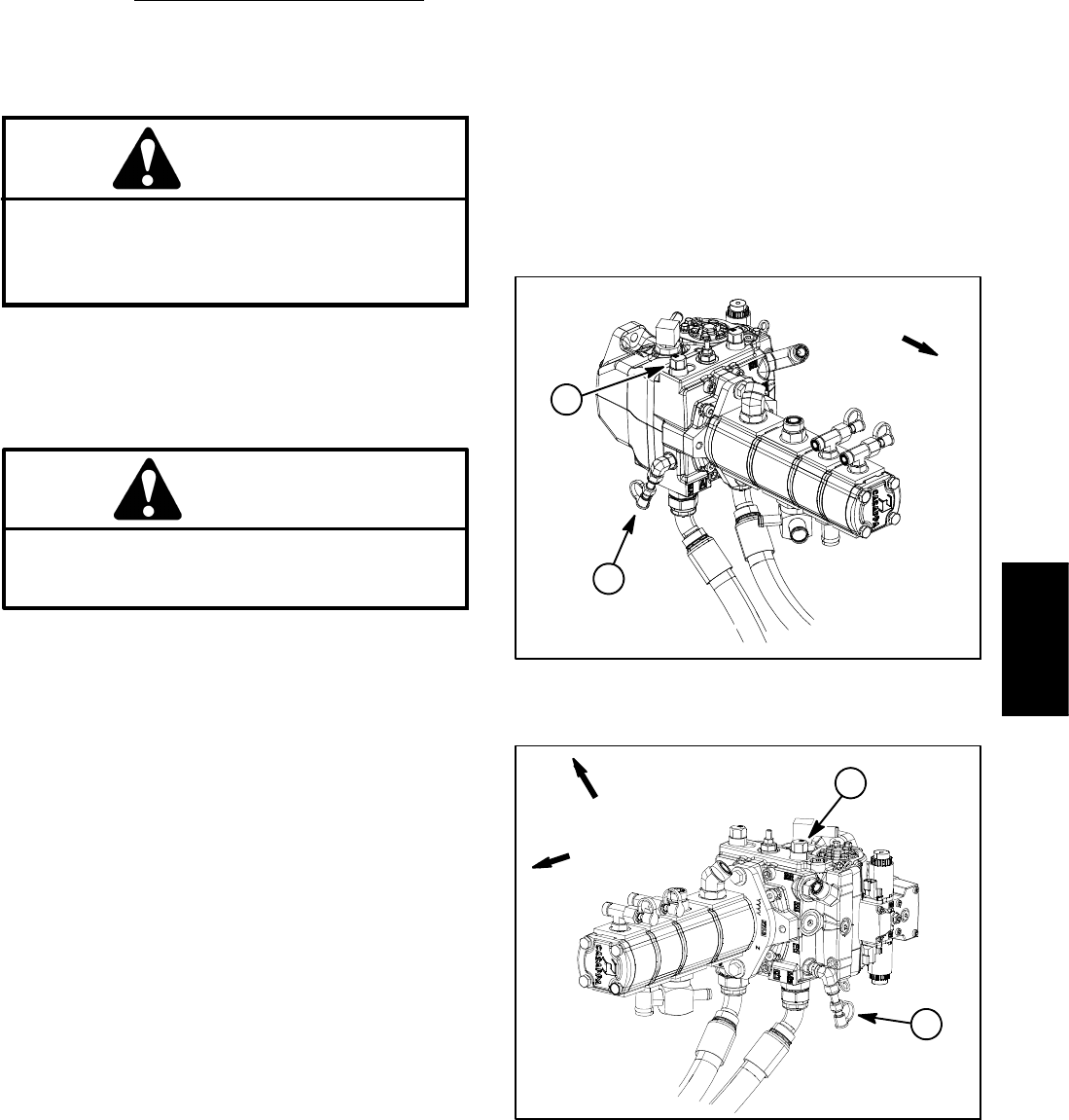

1. Reverse traction port 2. Reverse relief valve

Figure 29

FRONT

RIGHT

1

2

Hydraulic

System