Groundsmaster 4000--D/4010--D Page 6 -- 35 Axles, Planetaries and Brakes

Pinion Gear to Ring Gear Engagement

The final position of the pinion gear is verified by using

the gear contact pattern method as described in the fol-

lowing procedure.

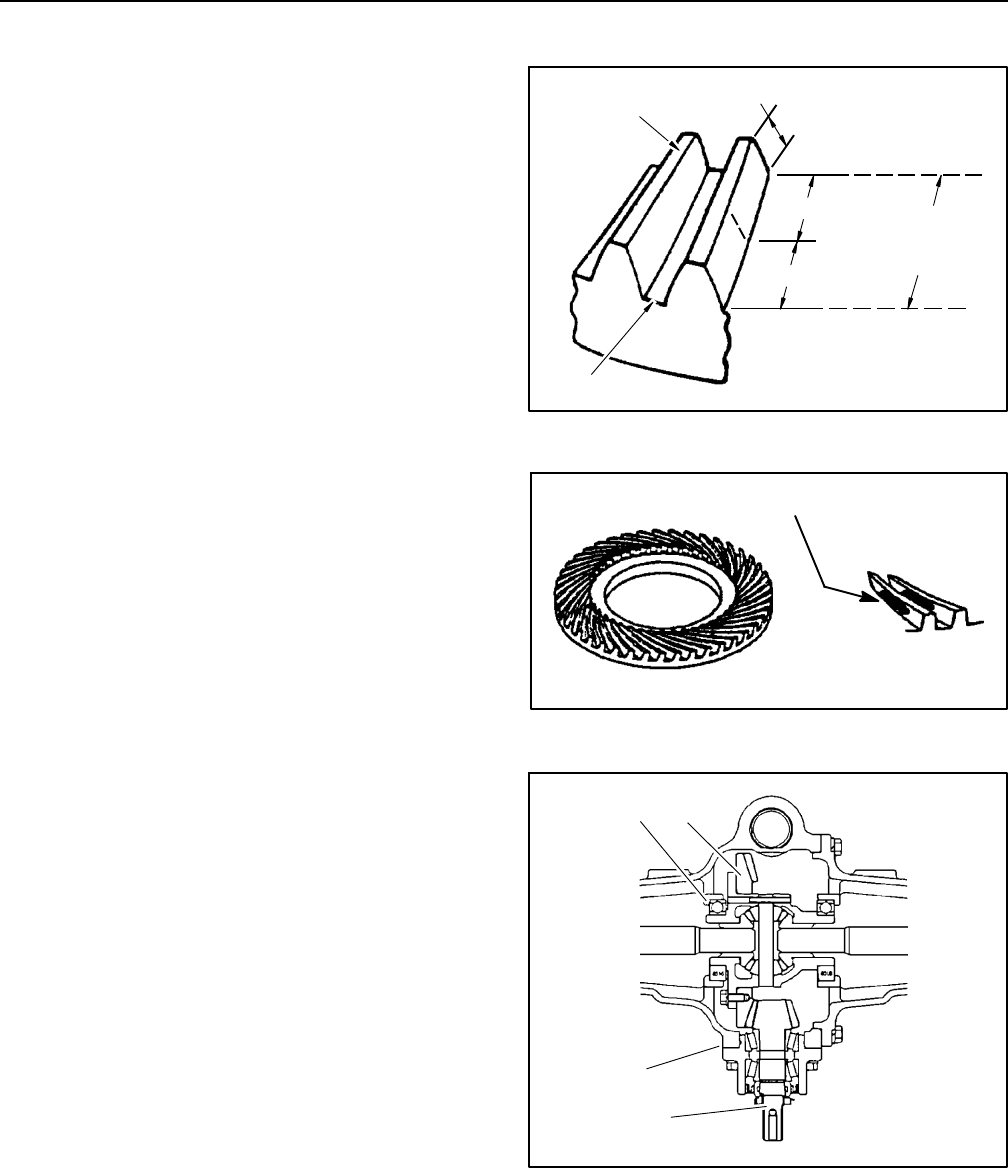

GEAR TOOTH DEFINITIONS (Fig. 46):

Toe -- the portion of the tooth surface at the end to-

wards the center.

Heel -- the portion of the gear tooth at the outer end.

Top Land -- top surface of tooth.

1. Paint the teeth of the ring gear, both drive and coast

side, with a gear marking compound, such as DyKemR

Steel Blue.

2. Install the input shaft/pinion gear assembly into axle

case.

3. While applying a light load to the ring gear, rotate the

pinion gear in the direction of forward travel until the ring

gear has made one complete revolution.

Ideal tooth contact observed on the ring gear should

cover morethan 35%of each tooth surface. Thecontact

areashouldbein thecenterof eachtooth andextend 1/3

to 1/2 way across each tooth from the toe end (Fig. 47).

Adjustments to the gear contact position are made by

moving the input shaft/pinion gear (bearing case shims)

or by moving the differentialgear case (differential bear-

ing shims) (Fig. 48).

NOTE: Bearing case shims are available in 0.004 inch

(0.10 mm) and 0.008 inch (0.20 mm) thickness.

NOTE: Differential bearing shims are available in

0.004 inch (0.10 mm), 0.008 inch (0.20 mm) and 0.016

inch (0. 40 mm) thickness.

Study the different contact patterns (Figs. 49 and 50)

and correct gear engagement as necessary.

NOTE: When making changes, note that two variables

are involved (see Gear Pattern Movement Summary in

this section of this manual).

Example: If the pinion gear to ring gear backlash is set

correctly to specifications and the bearing case shim is

changed to adjust tooth contact, it may be necessary to

readjust backlash to the correct specification before

checking the contact pattern.

Figure 46

TOE

HEEL

PROFILE

TOP LAND

ROOT

LENGTHWISE

BEARING

ARC

Figure 47

More than 35% total tooth contact

1/3to1/2ofentirewidth

from small end of tooth

1. Input shaft/pinion gear

2. Bearing case shims

3. Differential gear case

4. Differential bearing

shims

Figure 48

1

2

3

4