Groundsmaster 4000--D/4010--D Page 7 -- 9 Chassis

Removal (Fig. 6)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply park ing brake and remove

key from the ignition switch.

2. Remove side deck from lift arm (see Side Cutting

Deck Removal in Chapter 8 -- Cutting Decks).

3. Remove sidedeck rear arm assemblyfrom pivoth ub

(see Side Deck Rear Arm Assembly Removal in this

section).

4. Remove lift cylinder pin (item 28)that secures lift cyl-

inder to lift arm.

5. Drive out slotted roll pin (item 11) that retains lift arm

pivot shaft. Discard roll pin.

6. Support lift arm and pull lift arm pivot shaft from lift

armand frame.Locateand removethrustwashers (item

10) during pivot shaft removal. Note location of thrust

washers for assembly purposes.

A. If pivot shaft is difficult to remove, fabricate a pull-

er as shown in Figure 8.

B. Attach puller to end of pivot shaft using bolt and

flat washer.

C. Drivepivot shaftfromlift arm andframe withham-

mer.

7. Remove lift arm from machine.

Installation (Fig. 6)

1. Apply anti--s eize lubricant to lift arm pivot shaft.

2. Positionlift armto framewith thrustwashers properly

placed (Fig. 6). Make sure that there is a thrust washer

placed between the rear of the lift arm and frame. Addi-

tional thrust washers can be used to remove end play of

lift arm.

3. Slide pivot shaft into frame and lift arm until roll pin

holes in shaft and frame align. Make sure that lift arm

pivots freely after installation.

4. Install new slotted roll pin (item 11) to secure lift arm

pivot shaft.

5. If pivot hub (item 9) was removed from pivot shaft,

slide pivot hub onto shaft.Apply Loctite #242(or equiva-

lent) to cap screw threads and secure pivot hub with

washer and cap screw. Torque cap screw from 77 to 96

ft--lb (105 to 130 N--m).

6. Align lift cylinder with lift arm. Secure lift cylinder to

lift arm with lift cylinder pin (item 28). After lift cylinder is

secured, makesure thatupper hydraulicfitting onlift cyl-

inder does not contact frame.

7. Install side deck rear arm assembly (see Side Deck

Rear Arm Assembly Installation in this section).

8. If sensing plate (item 25) was removed from lift arm,

secure plate so it is rotated as far as possible toward

center of machine.

9. Positionand install side cuttingdeck tomachine (see

Side Cutting Deck Installation in Chapter 8 -- Cutting

Decks).

10.Lubricate lift arm grease fittings after assembly is

complete.

11.After assembly iscompleted, raiseand lower thecut-

tingdeck toverify thathydraulichoses andfittings donot

contact anything.

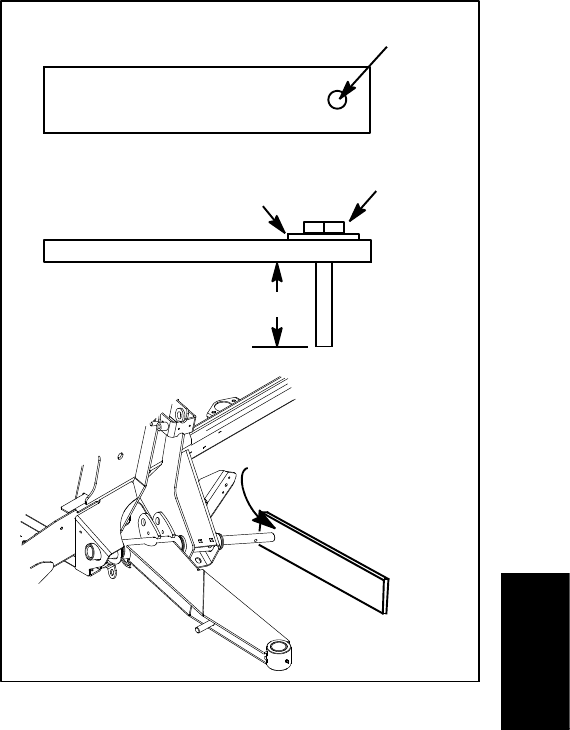

Figure 8

3” x 12” (3/8” to 1/2” thick) plate steel

9/16” hole

1/2” -- 13 UNC bolt

Flat washer

1” to 1 1/8”

Use hammer to drive

pivot shaft from lift arm

Chassis