Groundsmaster 4000--D/4010--DPage 5 -- 30Electrical System

Component Testing

For accurate resistance and/or continuity checks, elec-

trically disconnect the component being tested from the

circuit (e.g. unplug the ignition switch connector before

checking continuit y on the switch).

NOTE: For engine component testing information, see

the Yanmar Workshop Manual and Yanmar

Troubleshooting Manual.

CAUTION

When testing electrical components f or continu-

ity with a multimeter (ohms setting), make sure

that power to the circuit has been disconnected.

Ignition Switch

The ignition (key) switch is located on the control panel

and has three (3) positions: STOP, RUN and START

(Fig. 26). The To ro Electronic Controller (TEC) monitors

the operation of the ignition switch.

Testing

1. Park machine on a level surface, lower cutting

decks, engage parking brake and stop engine. Remove

key from ignition switch.

2. Before disconnecting the ignition switch for testing,

the switch and its circuit wiring should be tested as a

TEC electrical input using the InfoCenter Display (see

InfoCenter Display in this chapter). If input testing veri-

fies that the ignition switch and circuit wiring are func-

tioning correctly, no further ignition switch testing is

necessary. If, however, input testing determines that the

ignition switch and circuit wiring are not functioning cor-

rectly, proceed with the following ignition switch testing

procedure.

3. Remove controlarm coversto gain accessto ignition

switch (see Control Arm in the Service and Repairs sec-

tion of Chapter 7 -- Chassis).

4. Make sure ignition switch is in the OFF position. Dis-

connect wire harness connector from ignition switch.

5. Theignitionswitchterminals are identified in Figure

26 and the circuitry of the switch is shown in the chart in

Figure 27. With the use of a multimeter (ohms setting),

the switch functions can be tested to determine whether

continuity exists between the various terminals for each

switch position. Verify continuity between switch termi-

nals.

6. Replace ignition switch if testing determines that it is

faulty.

7. If the ignition switchtests correctly anda circuit prob-

lem still exists, check wire harness(see Electrical Sche-

matics and Wire Harness Drawings in Chapter 10 --

Foldout Drawings).

8. After testing is complete, connect machine wire har-

ness connector to ignition switch. Secure control arm

covers to machine with removed fasteners (see Control

Arm in the Service and Repairs section of Chapter 7 --

Chassis).

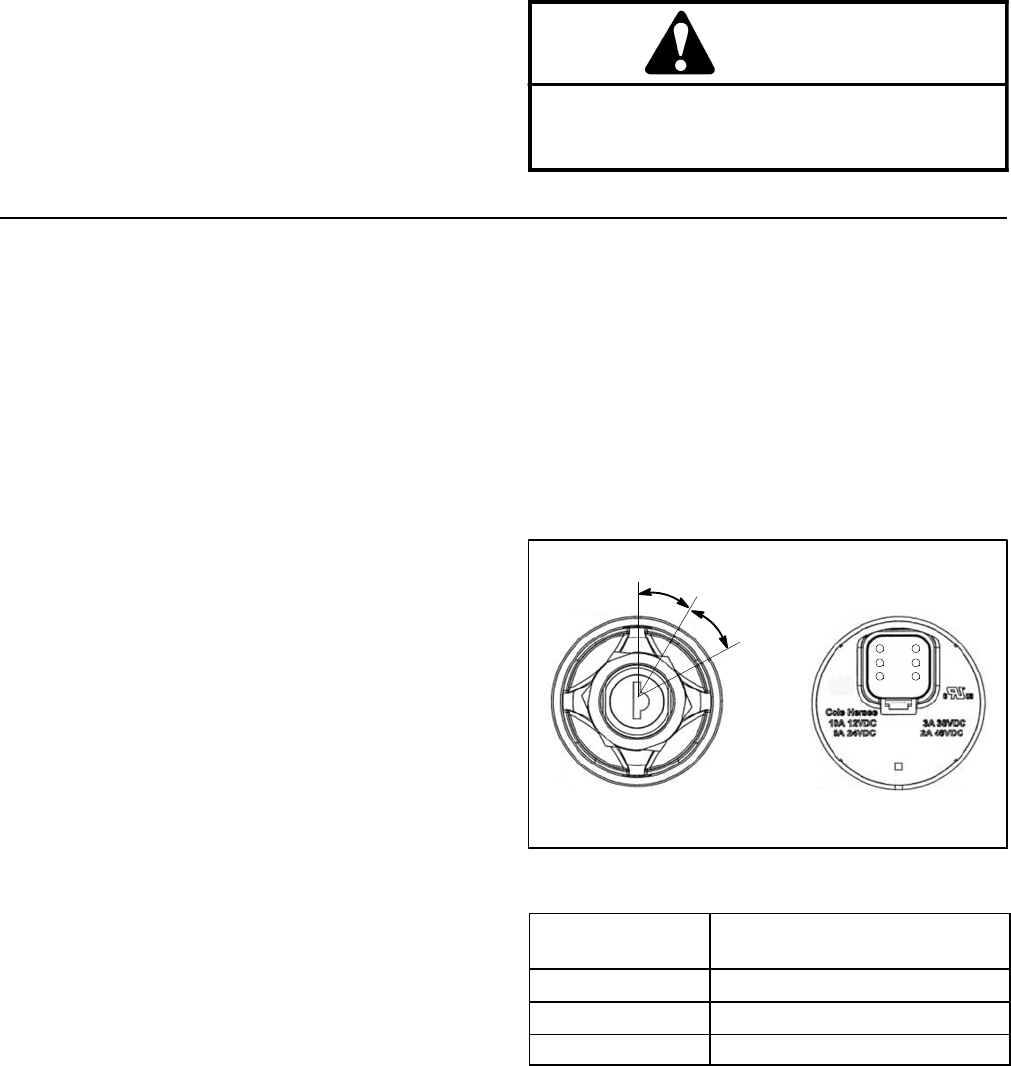

Figure 26

REAR VIEW

FRONT VIEW

START

STOP

RUN

3

2

4

5

6

1

SWITCH

POSITION

CIRCUITS

STOP 1+6

RUN 1+3+4+5+6

START 1+2+4+5+6

Figure 27

NOTE: Ignition switch terminals 1 and 6 are connected

internally.Terminals4 and5 arealso connectedinternal-

ly. These terminals should have continuity regardless of

switch position.