1 - 4

MELSEC-Q

1. OVERVIEW

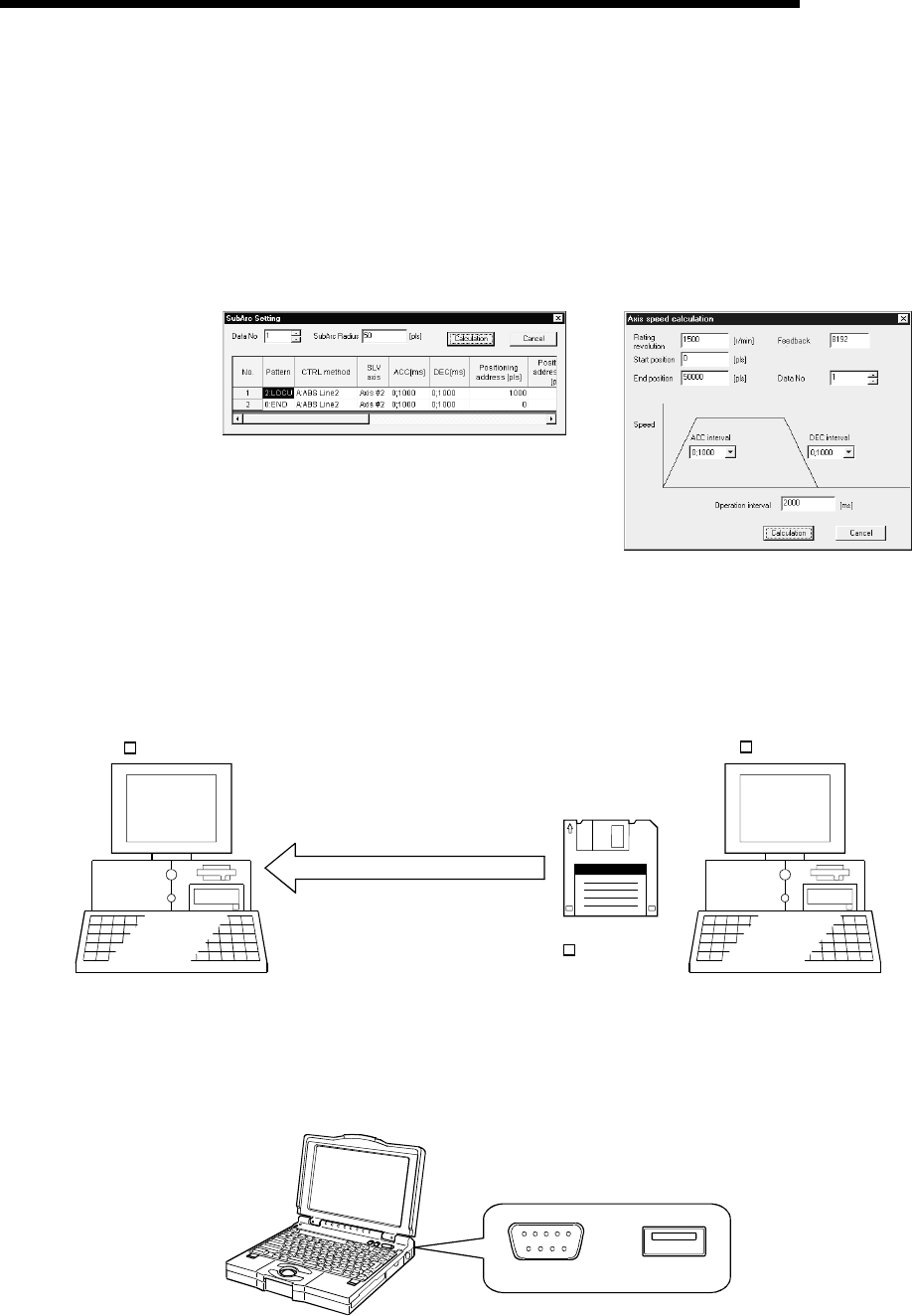

(5) Setting of optimum positioning data without complicated calculation

Positioning data can be set by sub arc setting and automatic axis speed setting.

Sub arc setting generates from the specified two linear interpolation control data

the circular interpolation control data in which the angle between two linear paths

is converted into a circular arc (curve) path.

Sub axis speed setting calculates the axis speed (command speed) from the

operation time, travel, acceleration/deceleration time and motor specifications.

[Sub arc] [Speed of axis setting]

These functions allow the optimum positioning data to be set without complicated

calculation and advance measurement.

(6) Ease of migration from AD75

You can read and use the data created on A series SW1IVD-AD75P-E and

SW0D5C-AD75P-E.

Valuable data is not wasted and can be utilized for QD75.

Open another format file.

Existing data created

on SW D5C-AD75P-E

SW D5C-QD75P-E

SW D5C-AD75P-E

(7) Versatility by compatibility with RS-232 and USB

If the personal computer does not have a free serial port, connection can be

made from the USB connector.

Especially for a notebook computer having a few serial ports, there are no

restrictions due to shortage of ports.

and

RS-232 USB