Installation Procedures Hydrastep Pressure Parts

24675030

2-5

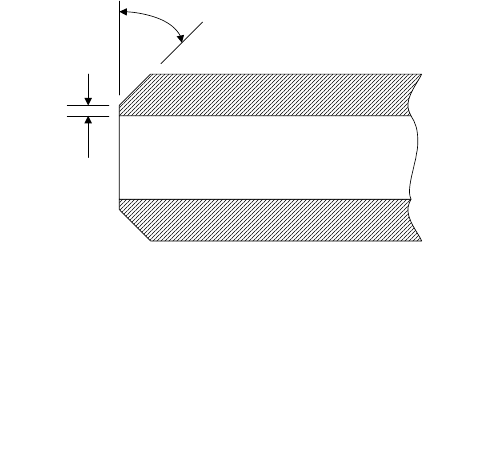

Figure 2.1 - Universal weld profile

The Steam and Water connections on the water column must be set to position the water

column at the correct level before they are welded in place, Figure 2.2 gives an example of

the water column installation. Normally, the water level of the drum will be between

electrodes 6 and 7 for a twelve port water column. However, due to the physical or operating

conditions, this could be offset. The steam leg must slope downwards to the water column

with a minimum gradient of 1 in 50 to ensure condensate circulation. The water leg must

slope downwards to the drum to prevent water from being trapped at the bottom of the water

column.

Caution: Care must be exercised to ensure that the pipework is not allowed to take the

unsupported weight of a standard water column. The weight of the column and

its associated pipework are fully supported - there must not be any load on the

welded pipework attachment points.

Installation should commence with the support of the column, see Figure 2.3. The water

column is attached to the supports which will carry the weight of the water column and allow

it to be accurately aligned with the drum steam and water connections before and during the

welding operation.

After the welding to the connecting pipework, valves and the fitting of the drain pipework is

complete, a further check on the level alignment must be carried out and adjustments made,

if necessary.

45°

1.5mm

For HP (210 bar) Material: SA106B

Size: 1" N.B, Sch. 160 pipe dim.

For HP (300 bar) Material: SA479 - 316

Size: 1" N.B, Sch. XXS PPE

For LP Material: SA106B

Size: 1" N.B, Sch. 80 pipe dim.