ProCore 648 Hydraulic SystemPage 4 – 39

2. Remove pump belt cover from machine (see Opera-

tor’s Manual).

3. Loosen the flange head screw (item 7) and flange nut

(item 11) that secure the drive belt idler pulley (item 10).

Lift idler pulley to allow removal of drive belt from the hy-

draulic pump pulley.

IMPORTANT: Before loosening pump pulley, mark

position of the pulley on the hydraulic pump shaft.

Pulley position is critical for proper alignment of the

hydraulic pump drive belt.

4. Loosen two (2) set screws that secure pump pulley

to the hydraulic pump shaft. Slide pulley from the pump

shaft. Locate and remove key from pump shaft.

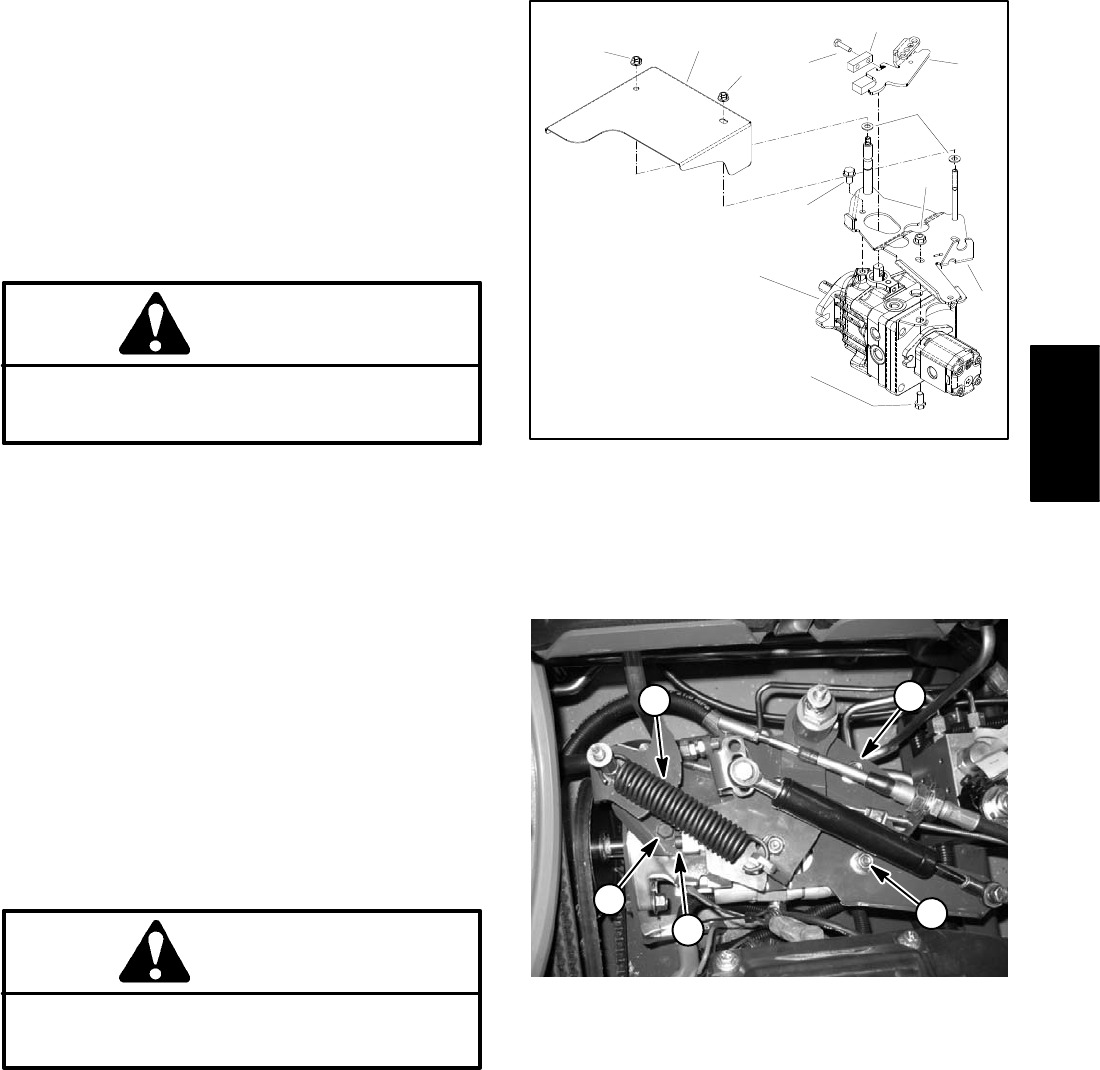

5. Remove two (2) lock nuts that secure pump shield to

pump (Fig. 32). Remove shield from pump. Locate and

retrieve two (2) flat washers from tops of studs on pump

control assembly.

6. Disconnect hydraulic pump controls (Fig. 32 and 33)

from the pump as follows:

CAUTION

The extension spring is under tension and may

cause personal injury during removal. Use cau-

tion when removing spring from neutral lever.

A. Remove extension spring from the neutral lever.

B. Loosen two (2) socket head screws (item 8, Fig.

32) that secure pump lever to pump trunnion shaft.

C. Remove two (2) cap screws with flange nuts

(items 2 and 4, Fig. 32) and washer head screw (item

9, Fig. 32) that secures control bracket to hydraulic

pump.

D. Carefully lift pump control assembly and position

away from pump.

7. Disconnect all hydraulic hoses and tubes connected

to the hydraulic fittings on the hydraulic pump assembly.

Allow hoses to drain into a suitable container. Plug or

cap openings of pump and hoses to prevent contamina-

tion.

CAUTION

Support hydraulic pump when removing it from

the pump support to prevent the pump from fal-

ling and causing personal injury.

8. Remove both flange head screws and flange nuts

securing the hydraulic pump to the pump support. Lift

pump assembly from the machine.

NOTE: If hydraulic fittings are to be removed from hy-

draulic pump, note correct orientation of fittings before

loosening the fittings.

9. Remove hydraulic fittings and o–rings from the pump

as required.

10.Discard all removed o–rings.

1. Hydraulic pump

2. Cap screw (2 used)

3. Control bracket

4. Flange nut (2 used)

5. Flat washer

6. Pump lever

7. Trunnion clamp

8. Socket hd screw (2 used)

9. Washer head screw

10. Lock nut

11. Pump shield

Figure 32

4

3

2

1

10

11

5

6

7

8

10

9

1. Extension spring

2. Socket head screw

3. Flange nut/cap screw

4. Washer head screw

Figure 33

3

3

1

4

2

Hydraulic

System