Rev. B

ProCore 648 Hydraulic SystemPage 4 – 23

6. Lift or jack machine so all wheels are off the floor to

allow flow through the traction circuit. Support machine

with jackstands or blocking.

7. Attach a heavy chain to the rear of the machine frame

and something immovable in the shop to prevent the

machine from moving during testing.

CAUTION

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

draulic oil.

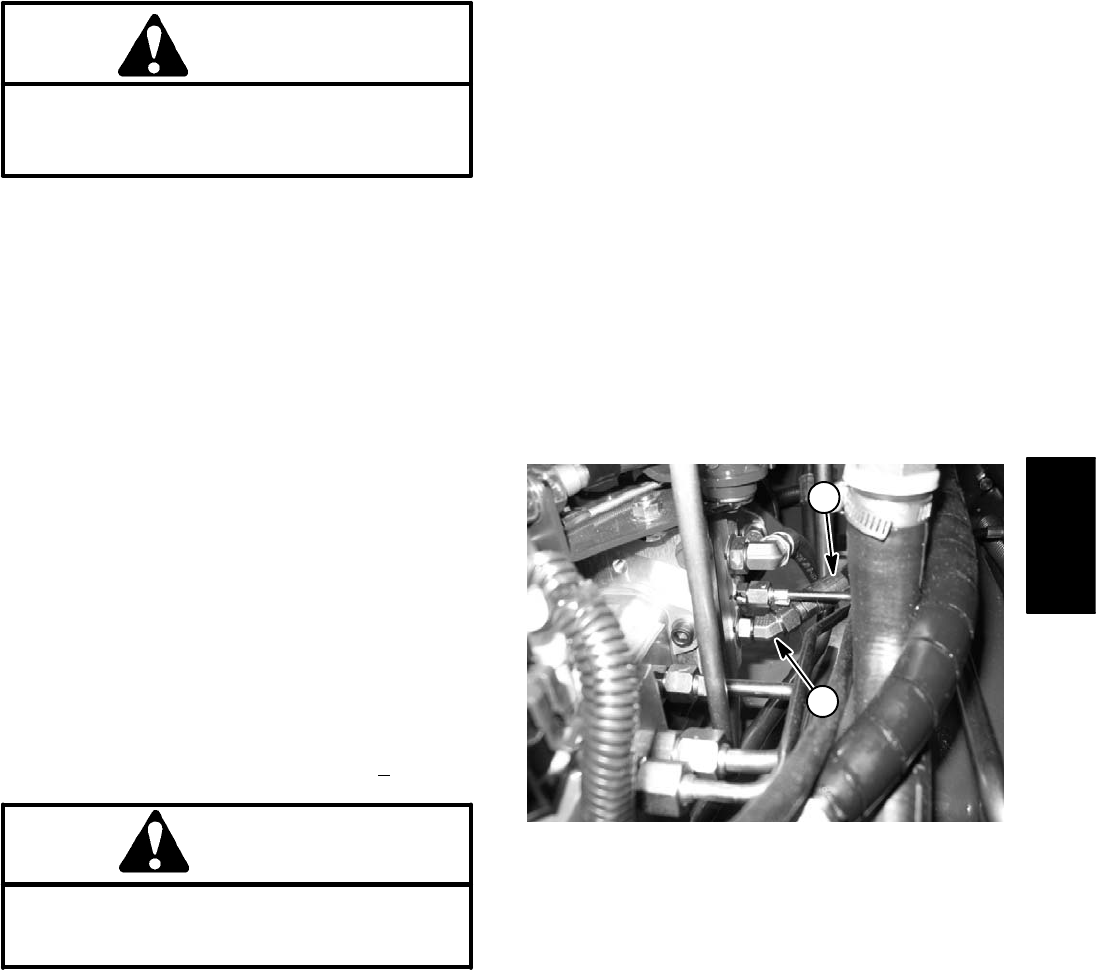

8. Clean hose fitting and disconnect hydraulic hose

from the lower 45

o

fitting on the rear side of the traction

pump (Fig. 19).

NOTE: An alternate testing location would be at the hy-

draulic hose connection to the P1 port of the front wheel

motor.

IMPORTANT: Make sure oil flow indicator arrow on

the flow meter is showing that the oil will flow from

the traction pump, through the tester and into the

disconnected hose.

9. Install hydraulic tester with flow meter and pressure

gauges in series with the traction pump and the discon-

nected hose. Make sure flow control valve on the

tester is fully open.

10.Check and adjust the oil level in the reservoir after

connecting hydraulic tester.

11. One person should operate the machine while

another person reads the tester.

12.Start and run engine at full speed (3400 +

50 RPM).

CAUTION

Use extreme caution when conducting test. The

wheels of the machine will be trying to move the

machine forward.

IMPORTANT: Do not rotate the traction pump trun-

nion shaft clockwise (reverse) during testing.

13.Using a wrench, slowly rotate traction pump trunnion

shaft counter–clockwise to the fully forward position.

14.While holding trunnion shaft fully counter–clockwise,

close flow control valve on tester until pressure gauge

reads 1000 PSI. As flow control valve is being closed,

engine speed will drop to approximately 3200 RPM.

Verify that pump speed is approximately 2500 RPM with

a phototac. Observe flow gauge.

TESTER READING: A pump in good condition

should have a flow of approximately 9.5 GPM

15.Open flow control valve on tester, return trunnion

shaft to the neutral position and turn off engine. Record

results of hydraulic flow test.

16.If flow is less than 7.6 GPM or a pressure of 1000 PSI

cannot be obtained, consider that a pump problem ex-

ists.

NOTE: Forward traction circuit relief pressure can be

determined with the same tester connections as this

test. See TEST NO. 4: Traction Circuit Relief Pressure.

17.When testing is complete, disconnect tester from

lower 45

o

fitting and hydraulic hose. Reconnect hose to

fitting. Secure pump control assembly to traction pump

(see Hydraulic (Traction/Charge) Pump Installation in

the Service and Repairs section of this chapter).

1. Lower 45

o

fitting 2. Hydraulic hose

Figure 19

2

1

Hydraulic

System