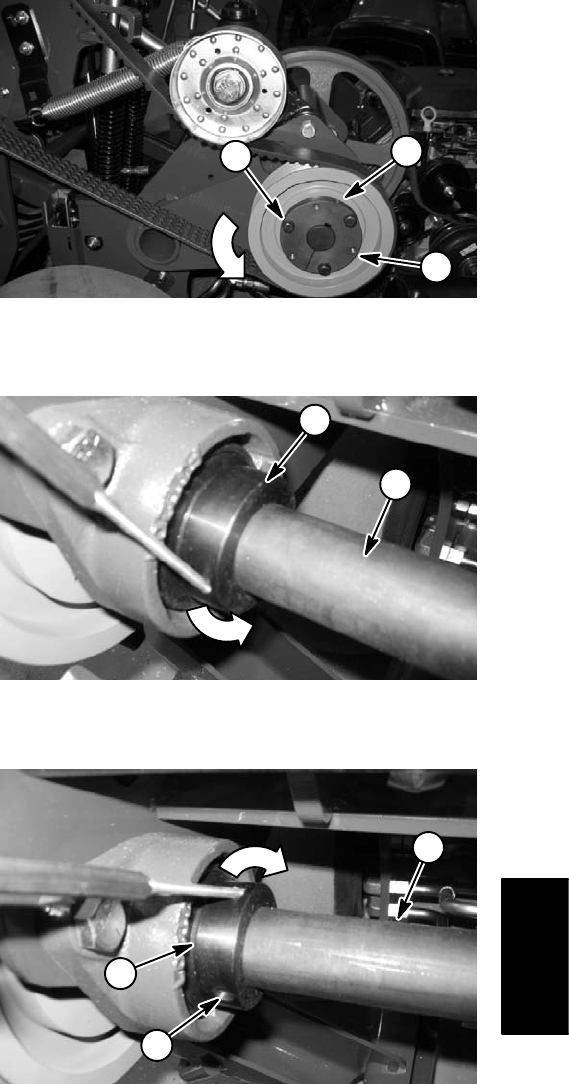

NOTE: Jackshaft rotates counterclockwise as viewed

from right side of machine (Fig. 18).

7. Loosen set screw that secures each flange mount

bearing locking collar to jackshaft. Using the blind hole

in bearing collar as a striking point, unlock collar from

jackshaft by rotating the collar in the opposite direction

of jackshaft rotation with a punch (Fig. 19).

8. Slide flange mount bearings from jackshaft.

Installation (Fig. 17)

1. Make sure that tapered surfaces of pulleys and taper

lock bushings are thoroughly clean (no oil, grease, dirt,

rust, etc.).

2. Slide flange mount bearings onto jackshaft.

3. Place woodruff keys (item 6) in jackshaft. Slide pul-

leys and taper lock bushings onto jackshaft making sure

that tapered surfaces of pulley and bushing align. Align

threaded holes of pulley with non–threaded holes of

bushing. Loosely install three (3) cap screws with lock

washers to both bushing and pulley assemblies.

4. Position jackshaft assembly to machine frame. Se-

cure flange mount bearings to frame with cap screws

and lock nuts.

IMPORTANT: When tightening bushing cap screws,

tighten in three equal steps and in a circular pattern

to prevent bushing flange damage.

5. Align taper lock bushing in primary pulley flush with

end of jackshaft and secure with set screw. Tighten

three (3) cap screws to a torque from 180 to 200 in–lb

(20.3 to 22.6 N–m) in three equal steps and in a circular

pattern to secure primary pulley and taper lock bushing.

6. Position jackshaft to align primary pulley and electric

clutch pulley on engine.

7. Using the blind hole in flange mount bearing locking

collars as a striking point, lock collars to jackshaft by ro-

tating the collars with a punch in the direction of jack-

shaft rotation (Fig. 20). Tighten set screw (item 11) to

secure each bearing locking collar to jackshaft.

8. Position secondary pulley on jackshaft to align sec-

ondary pulley and coring head pulley. Secure in position

with taper lock bushing set screw.

IMPORTANT: When tightening bushing cap screws,

tighten in three equal steps and in a circular pattern.

9. Secure taper lock bushing by tightening three (3) cap

screws to a torque from 180 to 200 in–lb (20.3 to 22.6

N–m) in three equal steps and in a circular pattern to se-

cure secondary pulley and taper lock bushing.

10.Install primary and secondary drive belts to jackshaft

pulleys (see Primary Drive Belt Installation and Secon-

dary Drive Belt Installation in this section).

11. Check that belt alignment is still correct. If needed,

readjust pulley location on jackshaft.

12.Install belt cover and rear hood to machine (see Op-

erator’s Manual). Remove service latch from coring

head before using machine.

3

1

2

DIRECTION

ROTATION

Figure 18

1. Cap screw/lock washer 3. Set screw

2. Threaded hole

2

LOOSEN

1

Figure 19

1. Flange mount bearing 2. Jackshaft

1

2

TIGHTEN

3

Figure 20

1. Flange mount bearing 3. Set screw

2. Jackshaft

Coring Head

ProCore 648 Page 7 – 15 Coring Head