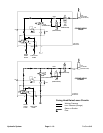

ProCore 648 Hydraulic SystemPage 4 – 9

Traction Circuit

The traction (piston) pump (P1) is driven by the engine

through the pulleys and pump drive belt. The traction cir-

cuit of the hydraulic system acts essentially as a closed

loop. Taking its suction directly from the return side of the

wheel motors of the traction circuit, the traction (piston)

pump supplies oil flow to the wheel motors through the

supply side of the traction circuit.

The gear pump (P2) is attached to the traction pump and

is directly coupled to it. The gear pump provides charge

oil to replace small amounts of traction pump internal oil

leakage. Hydraulic charge oil is supplied to the traction

circuit from the gear pump, through the lift control man-

ifold (manifold port P, proportional valve PV and man-

ifold port CHG) and past the charge circuit check valve

in the return side of the traction circuit. Proportional

valve PV ensures that sufficient gear pump flow is al-

ways available for the charge oil needs of the traction cir-

cuit. Gear pump flow in excess of charge circuit needs

is available to raise/lower the coring head. After charge

and raise/lower requirements are met, excess P2 flow

is directed to the hydraulic reservoir through the hydrau-

lic oil filter.

Forward Direction

With the engine running and the traction lever in the neu-

tral position, the traction pump supplies no flow to the

wheel motors. When the traction lever is moved to the

forward position, the linkage from the lever positions the

swash plate in the traction pump so oil flows out the low-

er port of the pump. Oil flow from the pump is directed

to the wheel motors (front motor first and then rear mo-

tors) and turns them in the forward direction. Maximum

forward traction pressure is limited by a 2900 PSI (200

Bar) relief valve located in the bottom of the pump as-

sembly.

Oil flowing from the rear wheel motors returns to the top

port of the traction pump and is continuously pumped

out the bottom port as long as the traction lever is held

in the forward direction.

Reverse Direction

The traction circuit operates essentially the same in re-

verse as it does in the forward direction. However, the

flow through the circuit is reversed. When the traction le-

ver is moved to the reverse position, the linkage from the

lever positions the swash plate in the traction motor so

oil flows out the upper port of the pump. Oil flow from the

pump goes to the wheel motors (rear motors first and

then front motor) and turns them in the reverse direction.

Maximum reverse traction pressure is limited by a 2900

PSI (200 Bar) relief valve located in the top of the pump

assembly.

Oil flowing from the wheel motors returns to the bottom

port of the traction pump and is continuously pumped

out the top port as long as the traction lever is held in the

reverse direction.

Hydraulic

System