Removal (Fig. 5)

1. Park machine on a level surface, fully raise coring

head, engage parking brake, stop engine and remove

key from the ignition switch. Secure coring head with

service latch.

2. Remove rear hood (see Operator’s Manual).

3. Remove two (2) lock nuts and hardened D washers

that secure rotolink damper to coring head frame (see

Rotolink Dampers in this section).

4. If outside stomper arm (#1 or #6) is to be removed:

A. If #1 stomper arm is being removed, remove sec-

ondary coring head drive belt (see Secondary Drive

Belt Removal in this section).

B. Remove cap screw and flat washer that retain

stomper arm to coring crankshaft.

C. If #6 stomper arm is being removed, remove

spacer tube (item 12) from coring crankshaft.

D. Support stomper arm assembly to prevent it from

falling during removal. Slide stomper arm from cor-

ing crankshaft. Carefully, lower stomper arm assem-

bly from frame.

5. If inside stomper arm (#2, #3, #4 or #5) is to be re-

moved:

A. Remove fasteners that secure coupling plate to

coupling on stomper to be removed (Fig. 7).

B. Remove cap screw and flat washer that secures

coupling and stomper arm to coring crankshaft.

C. Slide coupling from coring crankshaft. Locate

and retrieve square key.

D. Support stomper arm assembly to prevent it from

falling during removal. Slide stomper arm from cor-

ing crankshaft. Carefully, lower stomper arm assem-

bly from frame.

6. If necessary, remove retaining ring and ball bearing

from stomper arm.

7. If necessary, remove tines and tine holders from

stomper arm (see Operator’s Manual).

8. Remove rotolink damper components as needed

(see Rotolink Dampers in this section).

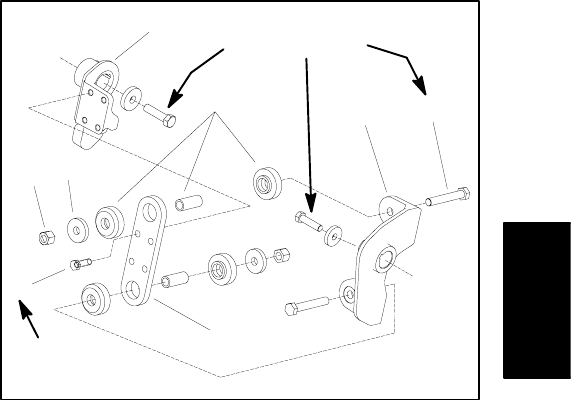

Installation (Fig. 5 and 7)

1. If removed, install ball bearing into upper end of

stomper arm and secure with retaining ring.

2. Install any rotolink damper components that were re-

moved during disassembly (see Rotolink Dampers in

this section).

3. Thoroughly apply antisieze lubricant to stomper arm

shaft surface on coring crankshaft.

4. Raise stomper arm assembly up through frame.

Slide stomper arm bearing onto coring crankshaft.

5. Secure stomper arm to coring crankshaft in the re-

verse order of disassembly.

A. Torque 5/8” cap screws from 150 to 170 ft–lb (203

to 230 N–m).

B. Torque 1/2” cap screws from 70 to 80 ft–lb (95 to

108 N–m).

6. Secure rotolink damper to coring head frame with

lock nut and hardened D washer (see Rotolink Dampers

in this section).

7. After assembly, rotate coring crankshaft by hand to

make sure that no binding occurs.

8. If removed, install tine holders and tines to stomper

arm (see Operator’s Manual).

9. If removed, install secondary coring head drive belt

(see Secondary Drive Belt Installation in this section).

10.Install rear hood (see Operator’s Manual). Disen-

gage service latch before machine use.

1

2

3

4

5

6

7

8

150 to 170 ft–lb

(203 to 230 N–m)

70 to 80 ft–lb

(95 to 108 N–m)

Figure 7

1. Coupling (#3 shown) 5. Coupling plate

2. Iso mount (2 used) 6. Cap screw (4 used)

3. Coupling (#2 shown) 7. Lock nut (2 used)

4. Cap screw (2 used) 8. Flat washer (2 used)

Coring Head

ProCore 648 Page 7 – 7 Coring Head