ProCore 648 Page 7 – 9 Coring Head

7. Disassemble bearing housing assembly:

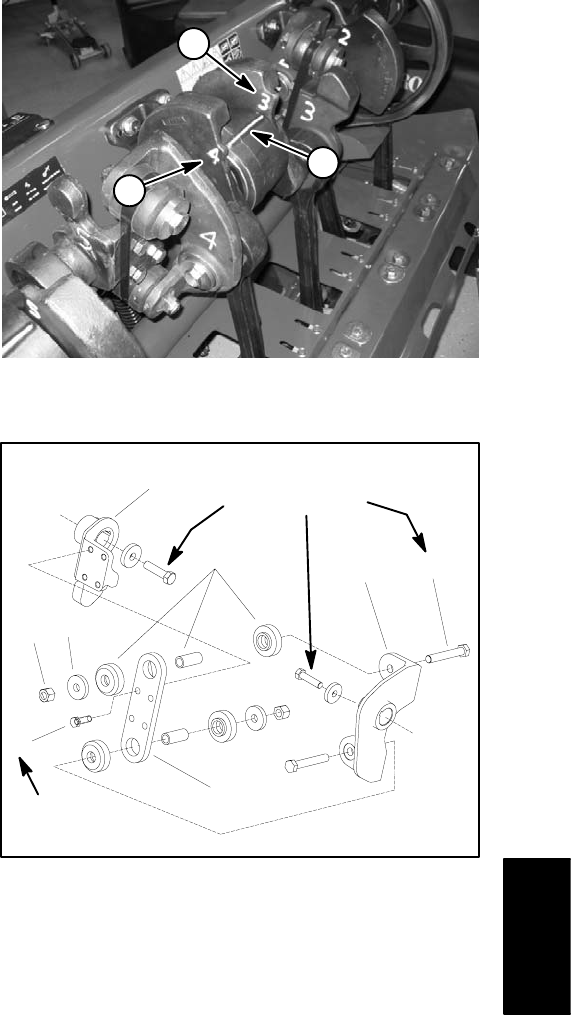

A. Remove cap screw (item 1) and flat washer (item

2) that fasten crankarms together. Take note of align-

ment of identification number on crankarm with tim-

ing mark on bearing housing (Fig. 9).

B. Slide crankarms from bearing housing.

C. If necessary, remove bearings and spacer from

bearing housing.

Installation (Fig. 8)

1. Install new bearings if they were removed from hous-

ing:

A. Install new bearing in one side of housing by

pressing on outer race of bearing.

B. Position spacer into bearing housing.

C. Install second new bearing by pressing on outer

race of bearing. Make sure that spacer is centered

between bearings.

2. Thoroughly apply antisieze lubricant to splines of

crankarms.

3. Install crankarms into bearing housing. Make sure

that correct identification number on crankarm is aligned

with timing mark on bearing housing (Fig. 9).

4. Install cap screw (item 1) and flat washer (item 2) to

retain crankarms. Do not fully tighten cap screw.

5. Drive new spring pins into coring head frame holes.

6. Position bearing housing assembly to coring head

frame and secure with four (4) cap screws, eight (8)

hardened washers and four (4) lock nuts. Torque fasten-

ers from 70 to 80 ft–lb (95 to 108 N–m).

7. Install stomper arms to crankarms on either side of

bearing housing (see Stomper Arm Installation in this

section). Do not fully tighten fasteners.

NOTE: With #1 crankarm aligned with cast mark on

bearing housing, all subsequent crankarm cast timing

numbers must be in line from 1 to 6.

8. Once all components have been installed, fully tight-

en fasteners in the following order. Tighten fasteners to

the torque specifications identified in Figures 8 and 10:

A. Cap screws that fasten crankarms.

B. Cap screws that secure top and bottom of stomp-

er arms.

C. Cap screws that secure coupling plates (Fig. 10).

D. Lock nuts that secure rotolink dampers to frame

(see Rotolink Damper Installation in this section).

9. After assembly, rotate coring crankshaft by hand to

make sure that no binding occurs.

10.If removed, install secondary coring head drive belt

(see Secondary Drive Belt Installation in this section).

11. Install rear hood (see Operator’s Manual). Disen-

gage service latch before machine use.

1. Housing timing mark 2. Crankarm position

Figure 9

1

2

2

1. Coupling (#3 shown)

2. Iso mount (2 used)

3. Coupling (#2 shown)

4. Cap screw (2 used)

5. Coupling plate

6. Cap screw (4 used)

7. Lock nut (2 used)

8. Flat washer (2 used)

Figure 10

1

2

3

4

5

6

7

8

150 to 170 ft–lb

(203 to 230 N–m)

70 to 80 ft–lb

(95 to 108 N–m)

Coring Head