Procedure for Wheel Motor Efficiency

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic reservoir is full.

2. Make sure that traction lever is adjusted to the neu-

tral position (see Operator’s Manual).

3. Park machine on a level surface with the coring head

fully raised. Make sure engine is off and the parking

brake is engaged. Secure coring head with service

latch.

4. Read Precautions For Hydraulic Testing in this sec-

tion.

CAUTION

draulic oil.

Operate all hydraulic controls to relieve system

pressure and avoid injury from pressurized hy-

5. Attach a heavy chain between the rear of the ma-

chine frame and an immovable object to prevent the ma-

chine from moving during testing.

6. If front wheel motor requires testing:

A. Both rear wheel motors should have hydraulic

lines connected. Block up both rear wheels off the

ground. Release parking brake so rear wheels can

turn.

B. Position front wheel on the ground. Immobilize

front wheel to prevent it from turning.

7. If a rear wheel motor requires testing:

A. Disconnect both hydraulic lines from rear wheel

motor that is not being tested. Cap disconnected hy-

draulic lines and plug wheel motor ports to prevent

contamination.

B. Front wheel motor should have hydraulic lines

connected. Block up front wheel off the ground.

C. Make sure parking brake is engaged to prevent

rear wheel rotation.

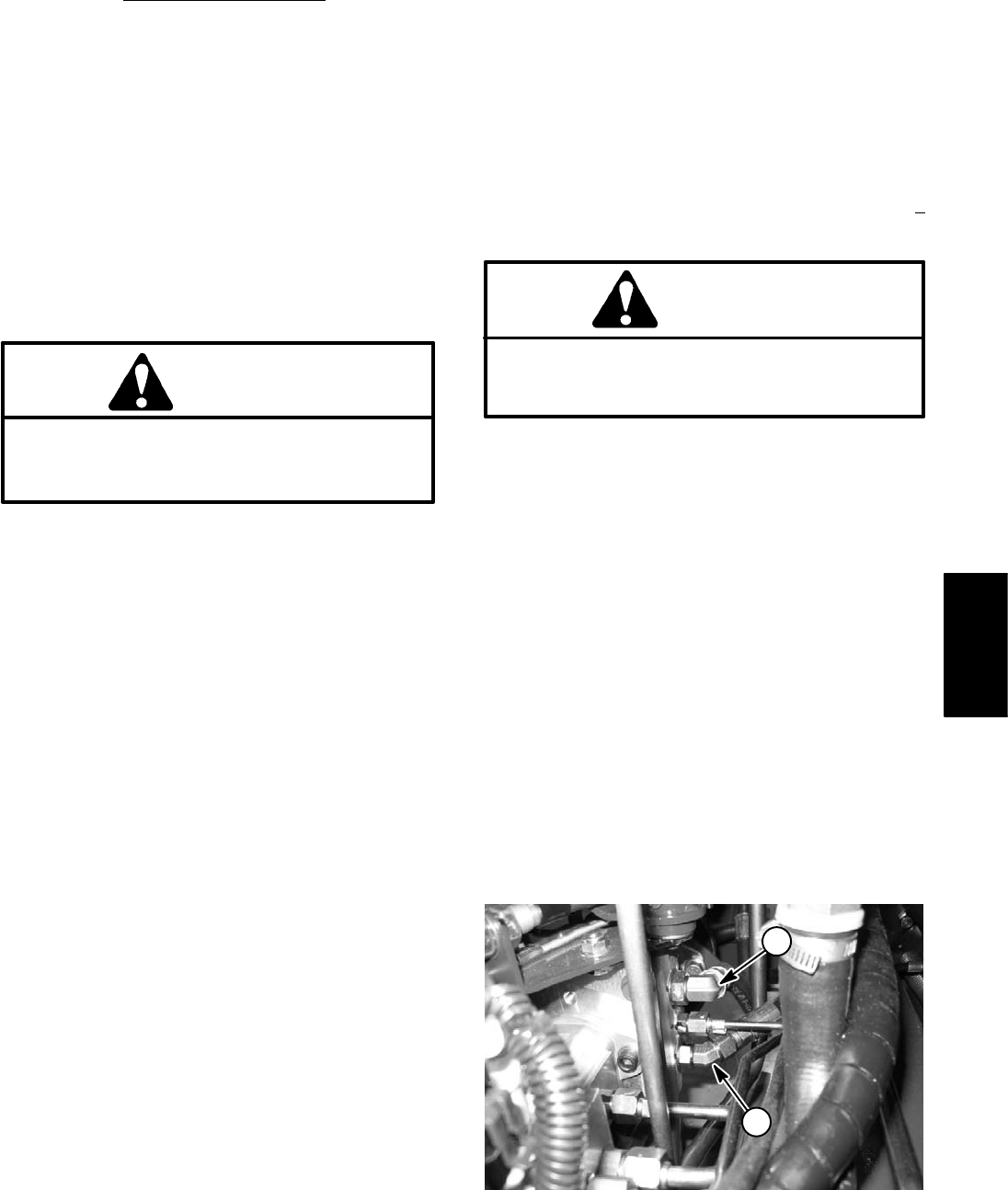

8. Clean hose fitting and disconnect hose from upper

90

o

fitting on traction pump (Fig. 25).

IMPORTANT: Make sure oil flow indicator arrow on

the flow gauge is showing that the oil will flow from

the wheel motor, through the tester and into the

traction pump fitting.

9. Install hydraulic tester with flow meter and pressure

gauges between the disconnected hose and traction

pump. Make sure flow control valve on the tester is fully

open.

10.Start engine and move throttle to full speed (3400 +

50 RPM).

CAUTION

Use extreme caution when performing test. The

tire(s) on the ground will be trying to move the

machine forward.

11. Slowly push traction lever in forward direction until

1000 PSI is displayed on the pressure gauge. Make sure

that wheel motor being tested does not rotate.

12.Wheel motor internal leakage will be shown on flow

meter in GPM. Flow should be less than 1.5 GPM for

the tested wheel motor.

13.Release traction lever and turn off engine. Record re-

sults of hydraulic flow test.

14.If specifications are not met, the tested wheel motor

needs to be repaired or replaced as necessary.

15.Reconnect hydraulic lines to wheel motor.

16.If additional wheel motor(s) require testing, complete

steps 6 to 14 for the remaining wheel motor(s).

17.Disconnect tester from machine. Reconnect hose to

pump connection.

1

2

Hydraulic

System

Figure 25

1. Upper 90

o

fitting 2. Lower 45

o

fitting

ProCore 648 Page 4 – 29 Hydraulic System