Pushing/Pulling Machine

IMPORTANT: If push/pull limits are exceeded, se-

vere damage to the piston (traction) pump may oc-

cur.

If it becomes necessary to push/pull the machine, push/

pull at a speed below 1 mph (1.6 kph), and for a dis-

tance less than 100 feet (30.5 meters). The piston

(traction) pump is equipped with a by–pass valve that

needs to be rotated counterclockwise (loosened) one

turn for pushing/pulling. The by–pass valve should be

torqued from 95 to 120 in–lb (10.7 to 13.6 N–m) before

the machine is returned to operation.

See Operator’s Manual for pushing/pulling procedures.

Check Hydraulic Fluid

The ProCore 648 hydraulic system is designed to oper-

ate on anti–wear hydraulic fluid. The reservoir (Fig. 8)

holds about 1.75 gallons (6.6 liters) of hydraulic fluid.

Check level of hydraulic fluid daily.

See Operator’s Manual for fluid level checking proce-

dure and hydraulic oil recommendations.

Relieving Hydraulic System Pressure

Before disconnecting or performing any work on the hy-

draulic system, all pressure in the hydraulic system

must be relieved. With the coring head fully raised, turn

key switch to OFF and allow engine to stop. Secure cor-

ing head with service latch.

To relieve hydraulic pressure in traction circuit, move

traction lever to both forward and reverse directions.

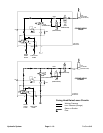

1

Figure 7

1. By–pass valve location

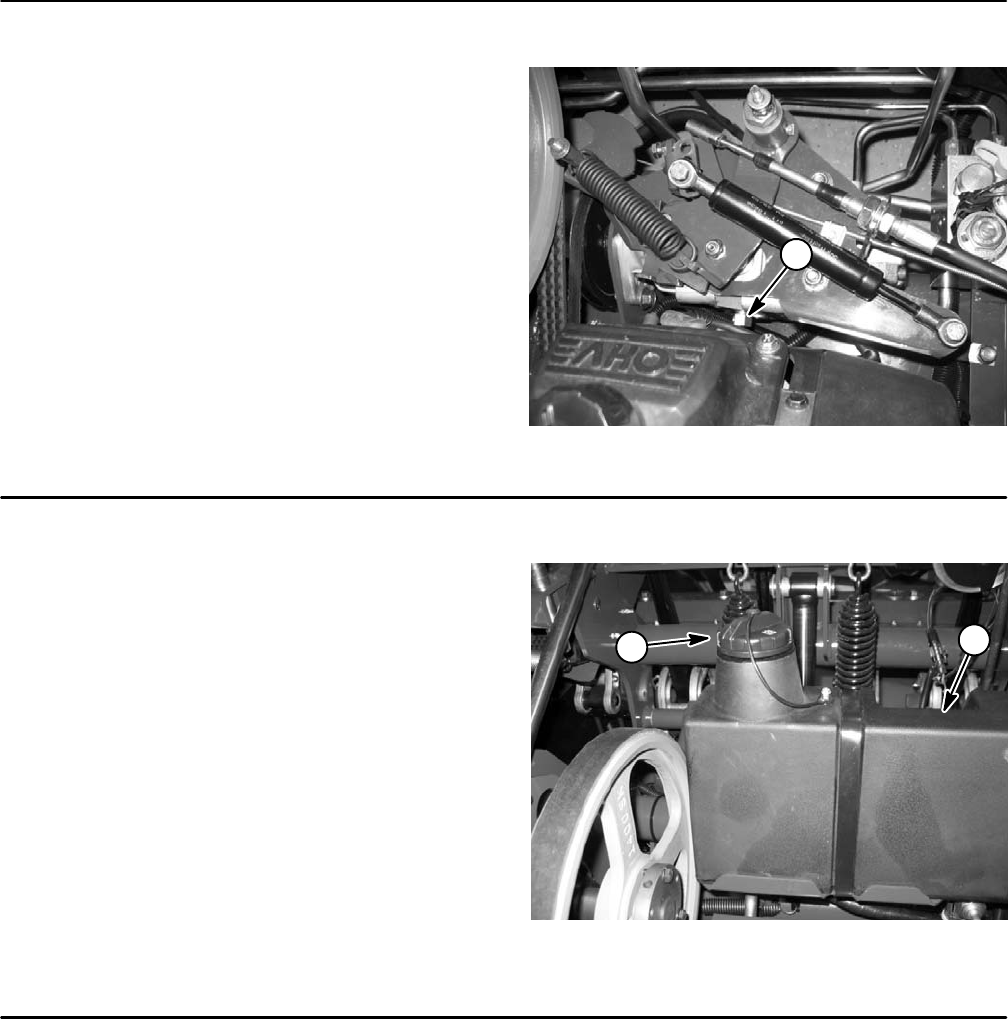

1

2

Figure 8

1. Hydraulic reservoir 2. Hydraulic reservoir cap

To relieve lift system pressure, turn key switch to ON

(engine not running). Move traction lever to forward di-

rection and depress lower switch on handle to lower cor-

ing head onto service latch. Return key switch to OFF

when pressure has been relieved. Remove key from the

ignition switch.

Hydraulic System Page 4 – 6 ProCore 648