Electric Clutch

An electric clutch is used to engage the coring head on

the ProCore 648. The electric clutch is mounted on the

engine crankshaft and engages when current is applied

to the clutch. The clutch also incorporates a magnetic

brake to stop clutch rotation when the clutch is de–ener-

gized.

When the ”OK to lower” latching circuit is closed and the

coring head is lowered enough to close the aeration #3

proximity switch, the clutch relay will be energized. This

energized relay provides a current path to energize and

engage the clutch. See Electric Clutch Circuit in the Cir-

cuit Operation section of this chapter for additional elec-

tric clutch information.

Testing

1. Park machine on a level surface, fully raise coring

head, engage parking brake, stop engine and remove

key from the ignition switch. Secure coring head with

service latch.

1. Remove pump belt cover from machine (see Opera-

tor’s Manual).

2. Remove exhaust system shield (see Exhaust Sys-

tem Removal in the Service and Repairs section of

Chapter 3 – Kohler Engine).

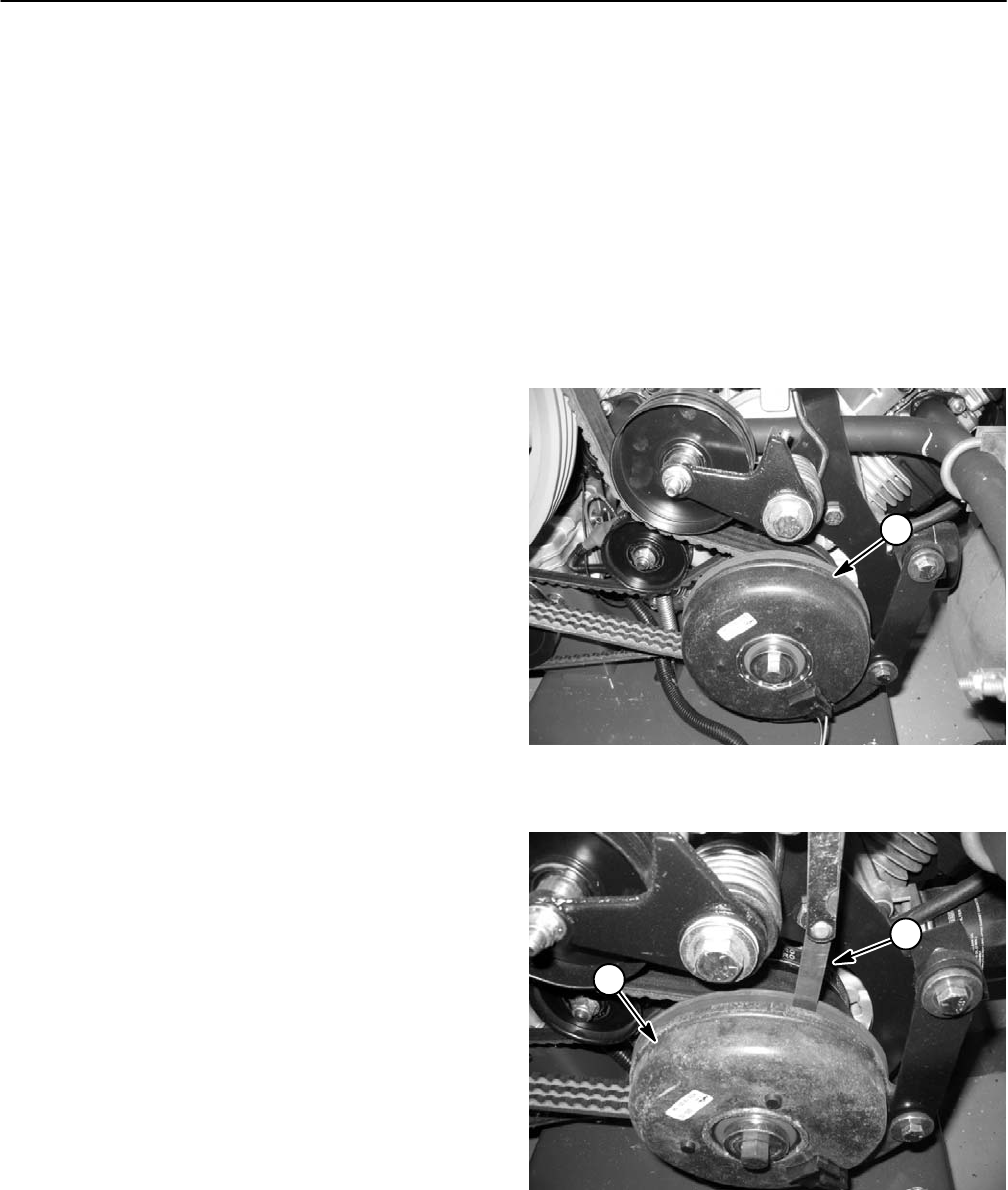

3. Locate electric clutch on engine crankshaft (Fig. 35).

Unplug machine wire harness connector from clutch.

4. For accurate resistance measuring, clutch should be

at approximately 68

o

F (20

o

C) when coil resistance is

measured.

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5 ohms or less). This resistance is due to the internal

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the component you

are testing.

5. Using a multimeter (ohms setting), verify clutch coil

resistance between the two terminals of the clutch wire

connector. Coil resistance should be 1.75 to 1.93 ohms.

6. If coil resistance is incorrect, replace clutch.

7. Measure gap between clutch rotor and armature

(Fig. 36). Gap should be less than .125” (3.18 mm). This

gap is not adjustable and increases as clutch compo-

nents wear. If gap exceeds .125” (3.18 mm), replace

clutch.

8. As an additional test, apply 12 volts to the terminals

of the clutch. The clutch should engage. If clutch does

not engage when voltage is applied, replace clutch.

9. If clutch removal is necessary, see Electric Clutch in

the Service and Repairs section of this chapter.

10.Install exhaust system shield (see Exhaust System

Installation in the Service and Repairs section of Chap-

ter 3 – Kohler Engine).

11. Install pump belt cover to machine (see Operator’s

Manual).

1

Figure 35

1. Electric clutch

1

2

Figure 36

1. Electric clutch

2. Feeler gauge

Electrical System

Page 5 – 26

ProCore 648