97

A.1 Introduction

Within the MintDrive control software, instantaneous axis position demands produced by the MintDrive

software must be translated into motor currents. This is achieved by closed loop control of the motor.

The motor is controlled to minimize the error between the demanded and measured positions (often

known as the following error). An incremental encoder or a resolver is used to measure the motor

position. Every 1ms* the MintDrive compares demanded and measured positions and calculates the

correct demand for the motor. The corrective signal is calculated by a PIDVF (Proportional, Integral,

Derivative and Velocity Feed Forward) algorithm.

On the following page, Figure A.1 shows the MintDrive’s positional, speed and current control loops.

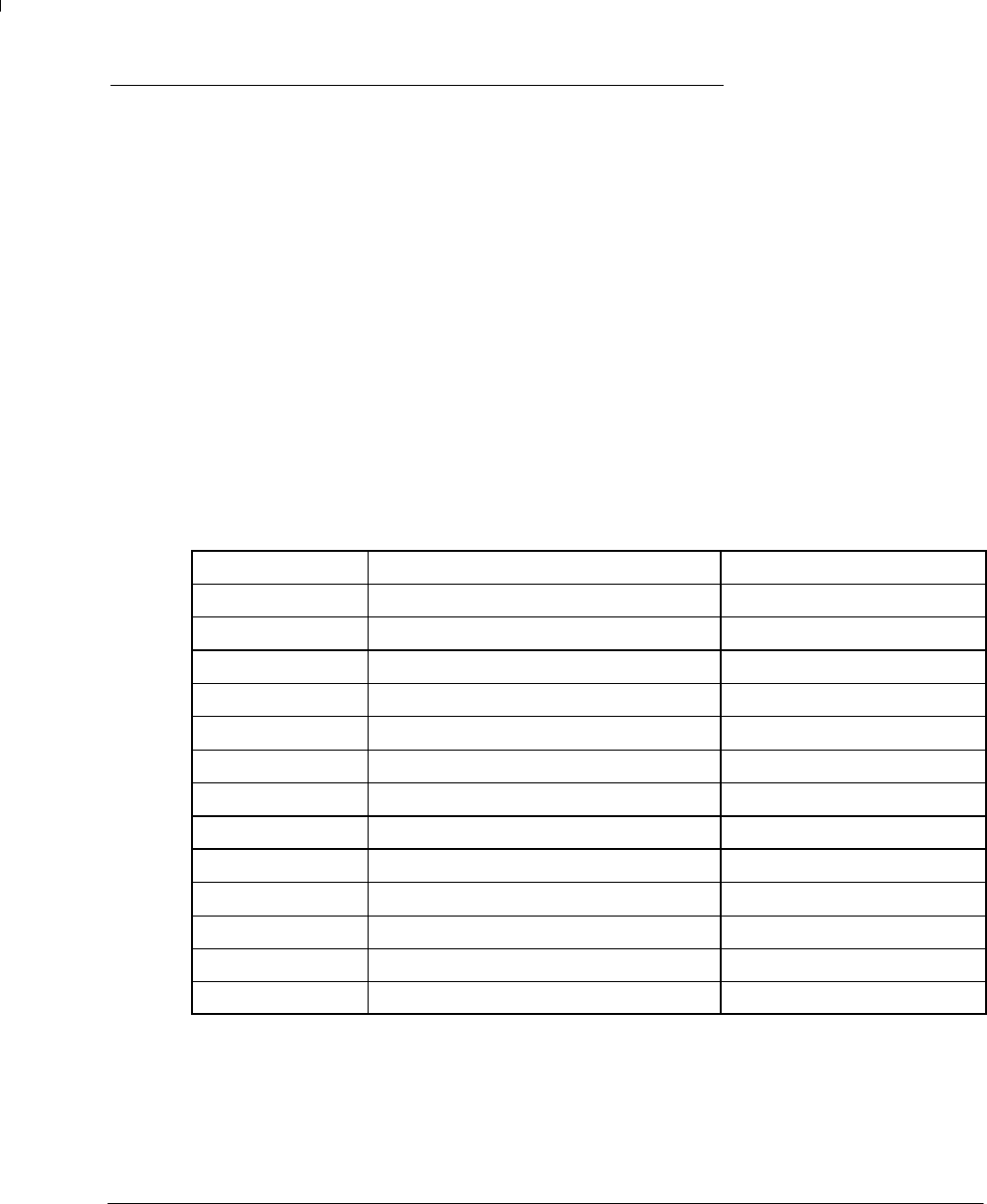

These are internal MintDrive control loops which can be tuned using the following keywords:

Purpose

Name Abbreviation / keyword

Position Control Proportional gain KPROP

Integral gain KINT

Velocity Feedback KVEL

Velocity Feedfoward KVELFF

Derivative gain KDERIV

Acceleration Feedforward KACCEL

Velocity Control Proportional gain KVPROP

Integral gain KVINT

Current Control Proportional gain KIPROP

Integral gain KIINT

* The 1ms sampling interval can be changed using the LOOPTIME keyword.

A Tuning

A