Groundsmaster 3000/3000–D

Page 5 – 17

Hydraulic System

Auxiliary Hydraulic Pump Efficiency Test (Model 30726 Hydraulic Kit)

A worn or damaged pump will by–pass oil and make the

pump less efficient. Eventually, enough by–passing will

occur to cause the cutting units to to stall in heavy cutting

conditions. Continued operation with a worn, inefficient

pump can generate a lot of heat and cause damage to

seals and other components in the hydraulic system.

Use a tester with pressure and flow capabilities.

Specification:

Minimum 12 GPM (45 liter/min.) at 2,500 PSI (173 Bar)

1. Make sure hydraulic oil is at normal operating temper-

ature by operating the machine for approximately 10

minutes.

2. Lower cutting unit, engage parking brake and stop the

engine.

3. Disconnect the large pressure hose from the coupler

at the pump. Disconnect the large return hose from the

coupler at the return filter. Install the tester between the

pump outlet and filter inlet.

IMPORTANT: Make sure the oil flow indicator on the

flow meter shows that the oil will flow from the

pump, through the tester and into the return filter.

Make sure the flow control valve is open before

starting the engine.

4. Start the engine and move the throttle control all the

way forward. Engage the PTO.

5. Slowly close the flow control valve until the gauge

reads 2,500 PSI (173 Bar). Read the flow meter. Disen-

gage the PTO, stop the engine and open the flow control

valve on the tester. If flow is less than 12 GPM (45 liter/

min.) the pump is inefficient and should be repaired or

replaced.

NOTE: The pump has an integral relief valve that is set

at 3,625 PSI (250 Bar). This relief valve protects the

pump from shock stress. If you cannot reach 2,500 PSI

(173 Bar) when closing the flow control valve on the

tester, this relief valve may be stuck open. This could be

caused by debris or contamination in the hydraulic sys-

tem.

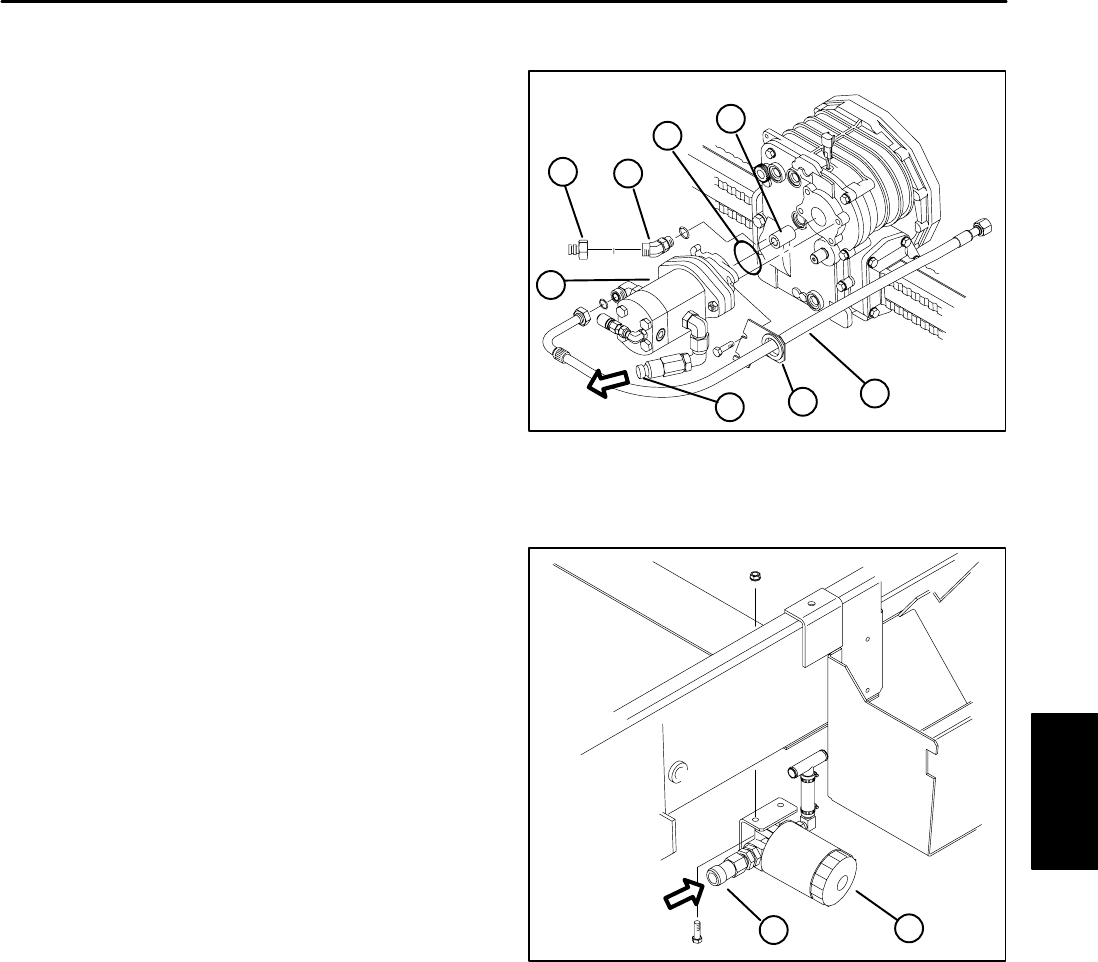

Figure 20

1. 45 degree fitting

2. Quick coupler nipple

3. Pump

4. Splined coupler

5. Flush faced coupler

6. Pump supply hose

7. Hose bracket

8. Square O–ring

1

3

2

4

5

6

7

8

Flow

Figure 21

1. Oil filter assembly

2. Flush faced fitting

1

2

Flow

Hydraulic System

and Transaxle