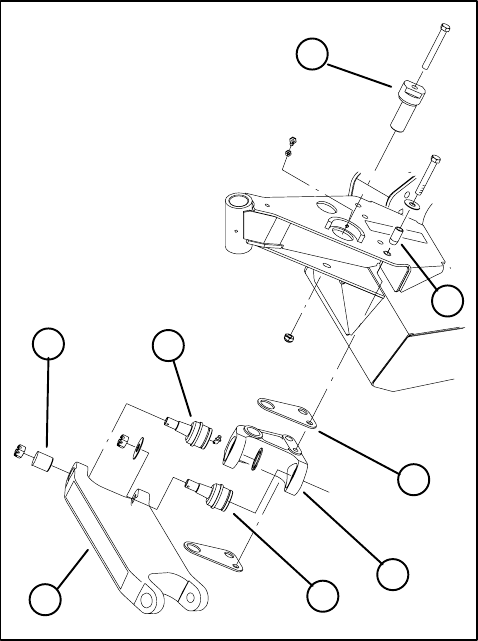

3. Pivot assembly re–assemble.

A. Press ball joints into pivot casting. Bottom ball

joint first.

B. Insert and orientate grease fittings to face up-

ward.

C. Install retaining rings on back side of ball

joints.

D. Clean any debris, oil, or dirt from tapered joints

on span casting and tapered sleeve. Any nicks

should be filed off.

E. Install pivot casting into chamber housing with

spacer plate on top and bottom of pivot casting.

F. Install pilot pin into 5/8 inch (16 mm) diameter

“pivot” hole and drive flush with top surface of

chamber housing.

G. Install eccentric cam through assembly with

identification mark facing forward. Use a small

amount of anti–seize compound on the diameter

interface between eccentric cam and pivot cast-

ing.

H. Install 7/16 inch grade 8 fasteners (and thick

washers) and tighten assembly such that eccen-

tric cam can still rotate pivot casting in chamber

housing.

I. Install span casting over ball joints in pivot

casting.

J. Use a soft mallet, tap tapered sleeve into place

in top ball joint position.

K. Torque ball joints as follows:

IMPORTANT: Failure to torque ball joints as fol-

lows can result in premature wear of ball joints

due to pre–load applied to ball joint sockets.

Bottom ball joint nut 50 ft–lbs (7 Kgm)

Top ball joint nut 50 ft–lbs (7 Kgm)

Bottom ball joint nut 125 ft–lbs (17 Kgm)

Top ball joint nut 125 ft–lbs. (17 Kgm)

NOTE: It is NOT recommended to use slotted

nuts on ball joints due to the need to over tighten

or back–off slotted nuts and to align cross holes

for use with a cotter pin.

1

2

3

4

4

5

6

7

Figure 25

1. Pivot casting 5. Span casting

2. Pivot pin 6. Tapered sleeve

3. Eccentric cam 7. Pivot spacer (2)

4. Ball joint

Contour 82 Cutting Unit

Page 10 – 16 Rev. A

Groundsmaster 3000/3000–D