Install Lift Arm Ball Joints

1. Adjust ball joint in each lift arm assembly until a di-

140 ft–lb (19 Kgm)

mension of 2.75 inches (70 mm) from end of lift arm to

center of ball joint is attained.

1

2

2.75 in. (70 mm)

then continue tightening

until slot in nut aligns

with cotter pin hole

84 inch

Cutting Units

Figure 18

1. Ball Joint

2. Lift Arm

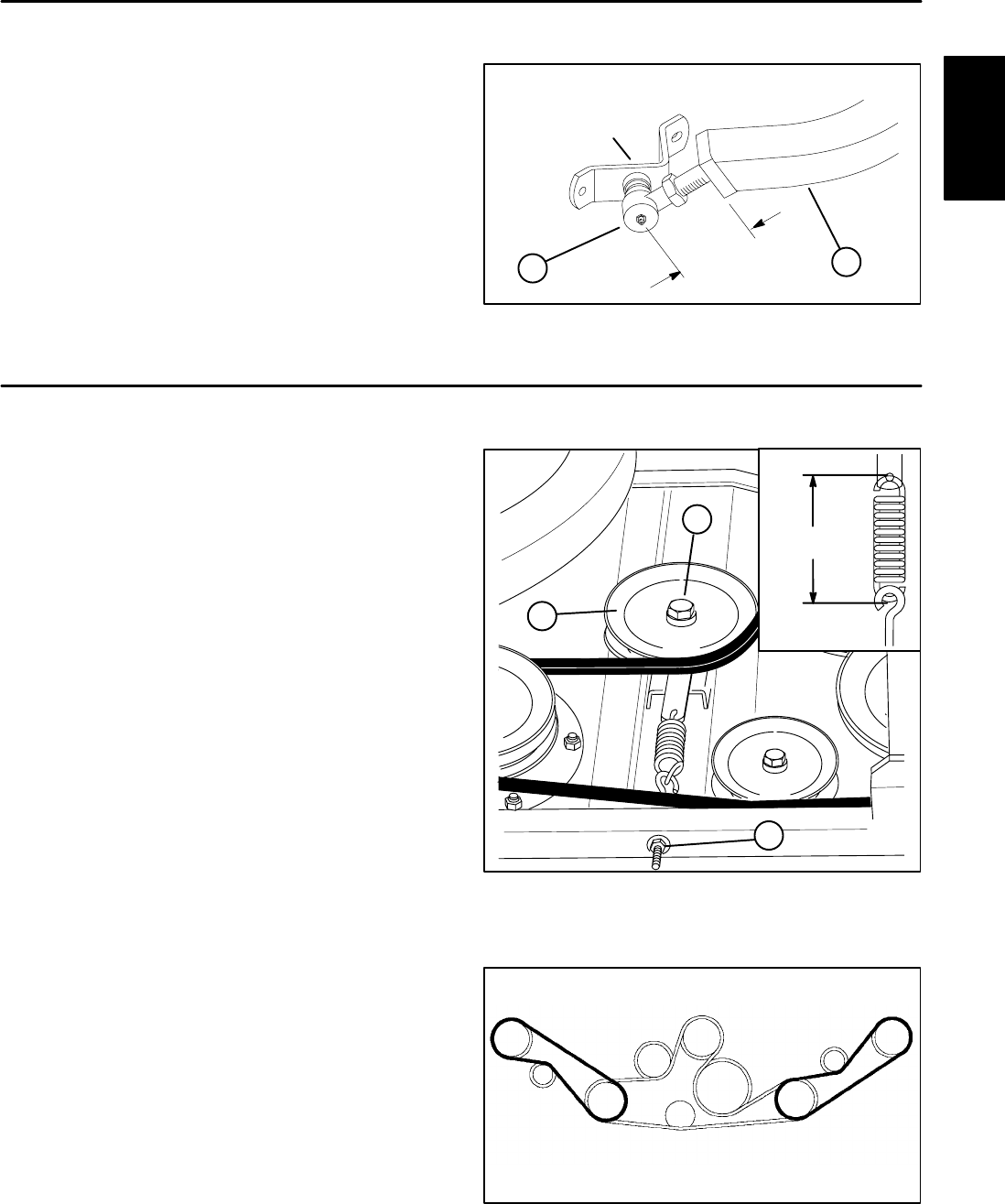

Drive Belt Replacement

The blade drive consists of three belts, one main drive

belt and two wing belts. The main drive belt is tensioned

by a fixed idler with a spring adjustment. The wing belts

have spring loaded idlers. All belts are very durable but

after many hours of use, the belt will show signs of wear.

Signs of a worn belt are: squealing when belt is rotating,

blades slipping when cutting grass, frayed edges, burn

marks and cracks. Replace any belt if any of these

conditions are evident. Adjust belt tension on main belt

after first 5 hours of operation to assure maximum dura-

bility and thereafter, check tension every 50 hours.

1. Lower cutting unit to the shop floor. Remove belt

covers from top of cutting unit and set covers aside.

2. Pull on spring loaded idlers and remove wing belts.

3. Loosen fixed idler pulley locking nut.

4. Loosen spring tensioning nut as required and re-

move belt.

5. Tighten spring tensioning nut until spring length is

4.35 inches (111 mm) inside spring loops.

6. Tighten idler pulley locking nut.

7. Pull on spring loaded idlers and install wing belts.

8. Install belt covers to top of cutting unit.

1

3

2

4.35 in. (111 mm)

Figure 19

1. Idler Pulley

2. Spring Tensioning Nut

3. Idler Pulley Locking Nut

Figure 20

Groundsmaster 3000/3000–D

Page 9 – 11

Rev. A

84 inch Cutting Units