Service and Repairs

Wheel and Tire Service

The tires are over–inflated for shipping. Therefore, re-

lease some of the air to reduce the pressure. Correct air

pressure in the front and rear tires is 15 psi (1 Bar).

Maintain even pressure in all tires to as-

sure a good quality–of–cut and proper machine perfor-

Kgm) after 1-4 hours of operation and again

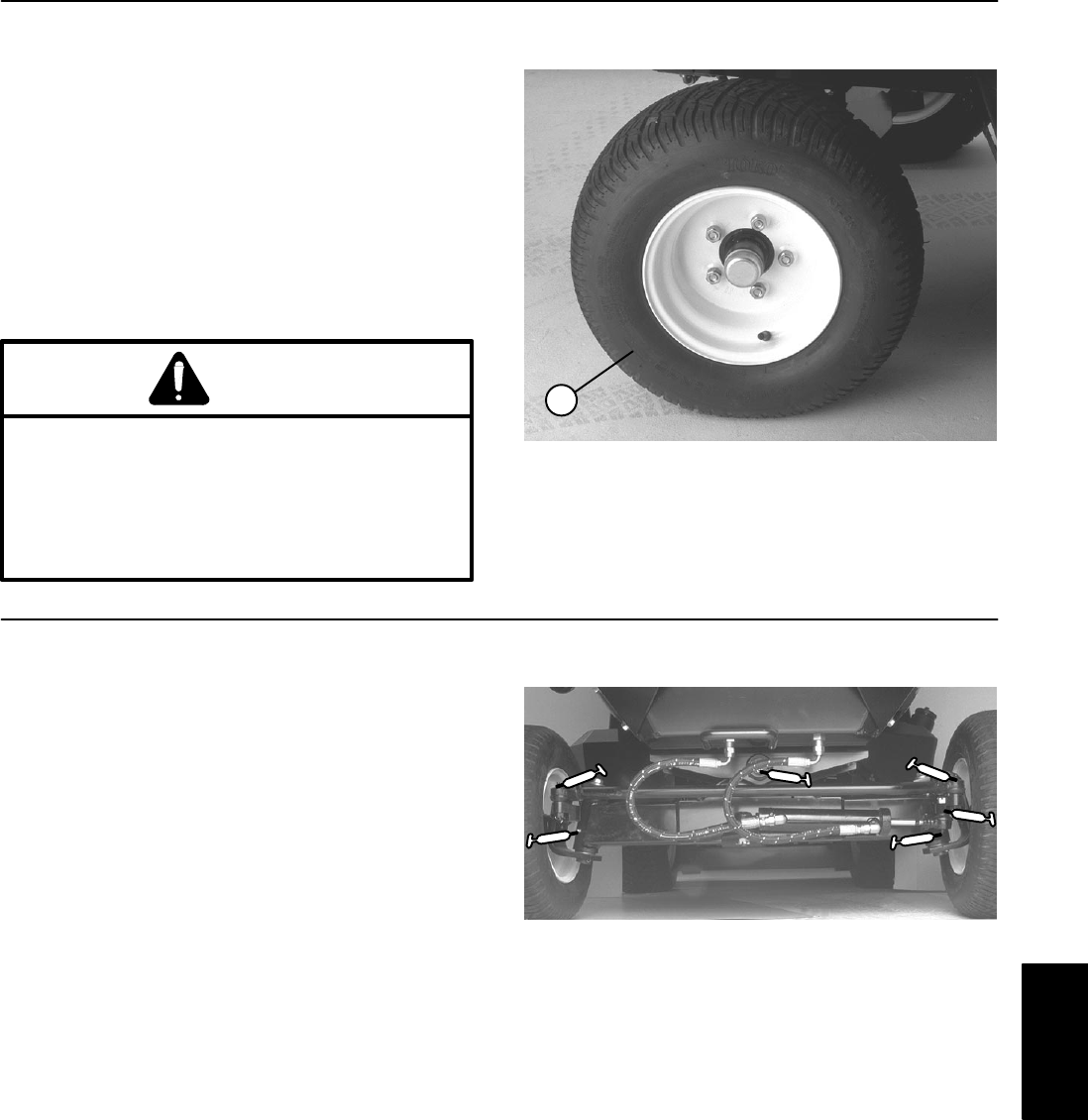

Figure 2

1. Rear wheel and tire

1

Check Tire Pressure

IMPORTANT:

mance. DO NOT UNDER INFLATE.

Check Wheel Nut Torque

WARNING

Torque wheel nuts to 70–80 ft–lb (10–11

after 10 hours of operation and every 200

hours thereafter. Failure to maintain proper

torque could result in failure or loss of wheel

and may result in personal injury.

Lubrication

The machine has grease fittings that must be lubricated

regularly with No. 2 General Purpose Lithium Base

Grease. If machine is operated under normal condi-

tions, lubricate all bearings and bushings after every 50

hours of operation or immediately after every washing.

Steering cylinder ball joint, Rear axle tie rod (2), Rear

axle pivot (1) Rear Spindle Shafts (2).

Figure 3

Groundsmaster 3000/3000–D

Page 7 – 3 Rev. A

2WD Rear Axle

2WD Rear Axle